Simplified method for simulating silicon carbide fiber high-temperature water-oxygen environment by using quartz sealing tube

A silicon carbide fiber and quartz tube technology is applied in the field of ceramic fiber materials to achieve high safety and save experimental costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

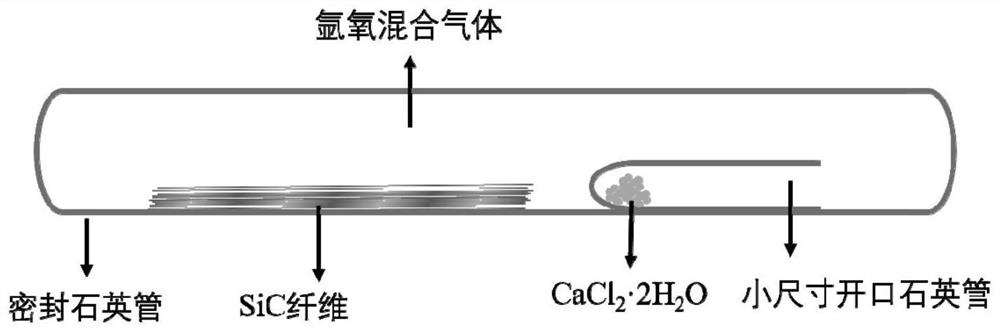

Embodiment 1

[0048] Simulated engine combustion environment (P H2O :P O2 :P Ar=14:8:78), the length of the quartz tube is 200mm, the inner diameter of the tube is 18mm, the treatment temperature of the muffle furnace is 1050°C, and when the mass reaction of SiC fiber is 10%, according to the chemical reaction equation (1), (2) and the ideal The gaseous equation calculates that the mass of silicon carbide fiber is 0.0172g, CaCl 2 2H 2 The mass of O is 0.0048g, the partial pressure of oxygen at room temperature is 1.8×103Pa, and the partial pressure of argon at room temperature is 1.75×104Pa. Use an electronic balance to weigh the required silicon carbide fiber and CaCl 2 2H 2 O mass; then CaCl 2 2H 2 O is packed into a small-sized quartz tube with an open end and packed into the selected quartz tube together with the silicon carbide fiber; finally, the quartz tube is vacuumized; finally, argon and oxygen with a certain partial pressure are filled into the quartz tube , and use a hig...

Embodiment 2

[0050] Simulated engine combustion environment (P H2O :P O2 :P Ar =14:8:78), the length of the quartz tube is 200mm, the inner diameter of the tube is 18mm, the treatment temperature of the muffle furnace is 1350°C, and when the mass reaction of SiC fiber is 10%, according to the chemical reaction equation (1), (2) and the ideal The gaseous equation calculates that the mass of silicon carbide fiber is 0.0145g, CaCl 2 2H 2 The mass of O is 0.0040g, the partial pressure of oxygen at room temperature is 1.5×103Pa, and the partial pressure of argon at room temperature is 1.47×104Pa. Use an electronic balance to weigh the required silicon carbide fiber and CaCl 2 2H 2 O mass; then CaCl 2 2H 2 O is packed into a small-sized quartz tube with an open end and packed into the selected quartz tube together with the silicon carbide fiber; finally, the quartz tube is vacuumized; finally, argon and oxygen with a certain partial pressure are filled into the quartz tube , and use a hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com