Insulated gate bipolar transistor and manufacturing method thereof

A technology of bipolar transistors and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of increasing conduction voltage drop and increasing turn-off time, so as to reduce turn-off time and turn-off time. The effect of breaking loss and improving recombination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0112] Insulated gate bipolar transistors (IGBTs) can generally be classified into lateral IGBTs and vertical IGBTs. IGBTs fabricated based on a silicon-on-insulator (SOI) process are typically lateral. Wherein, the horizontal IGBT means that the plane where the transistor structure is located is parallel to the plane where the substrate is located, and the plane where the vertical IGBT transistor structure is located is perpendicular to the plane where the substrate is located.

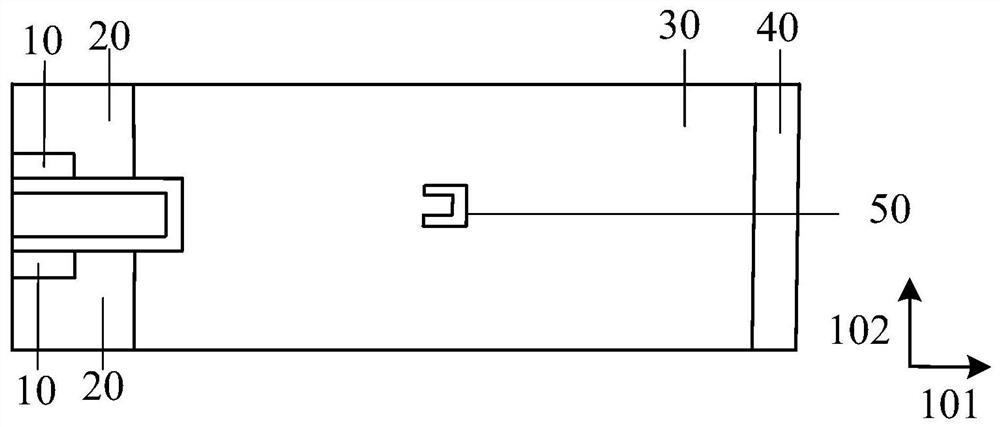

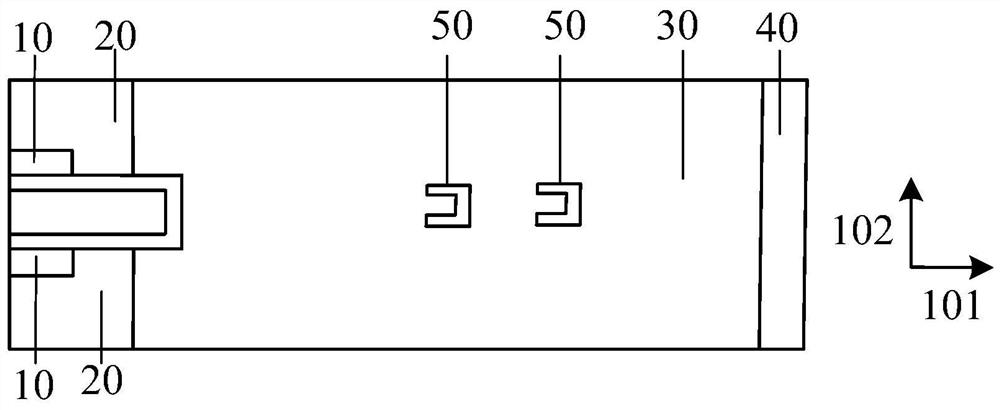

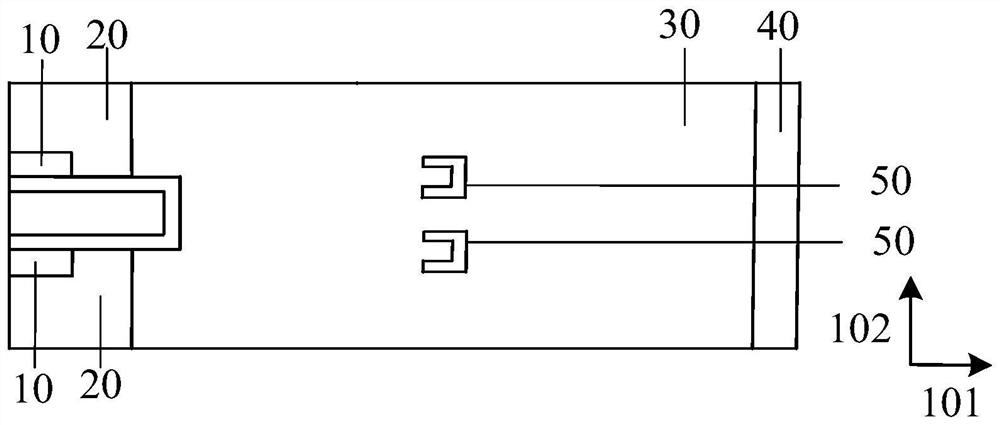

[0113] Figure 5 A structural diagram of an SOI lateral insulated gate bipolar transistor is shown, which includes an emitter region 10, a body region 20, a drift region 30, a collector region 40, a polysilicon gate 60, a gate oxide layer 70, and a buried oxide layer 80 and substrate 90.

[0114] When the insulated gate bipolar transistor is turned on, electrons are injected from the emitter region 10 to the drift region 30, holes are injected from the collector region 40 to the drift region 30, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com