A non-destructive laser cleaning method

A technology of laser cleaning and cleaning room, which is applied in the direction of cleaning methods and appliances, chemical instruments and methods, optical testing defects/defects, etc., and can solve problems such as easy emission of protective gas, damage to workpiece substrates, and damage to workpiece cleaning. Achieve non-destructive cleaning, avoid excessive cleaning, and save operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

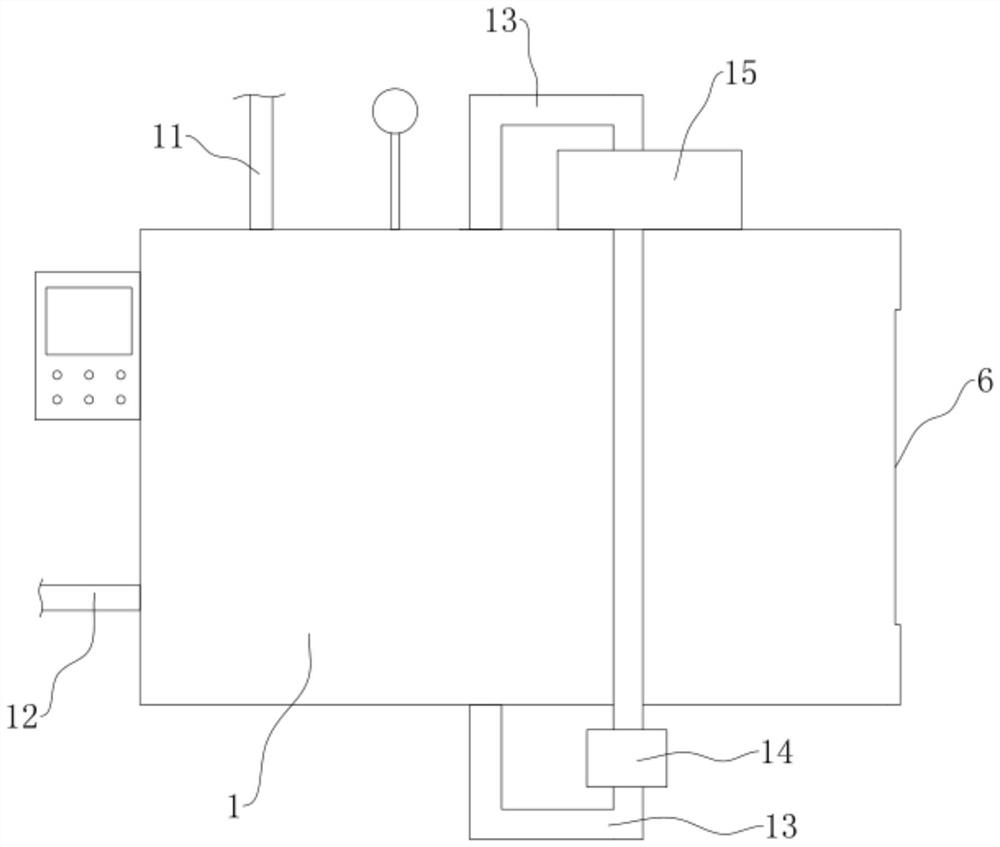

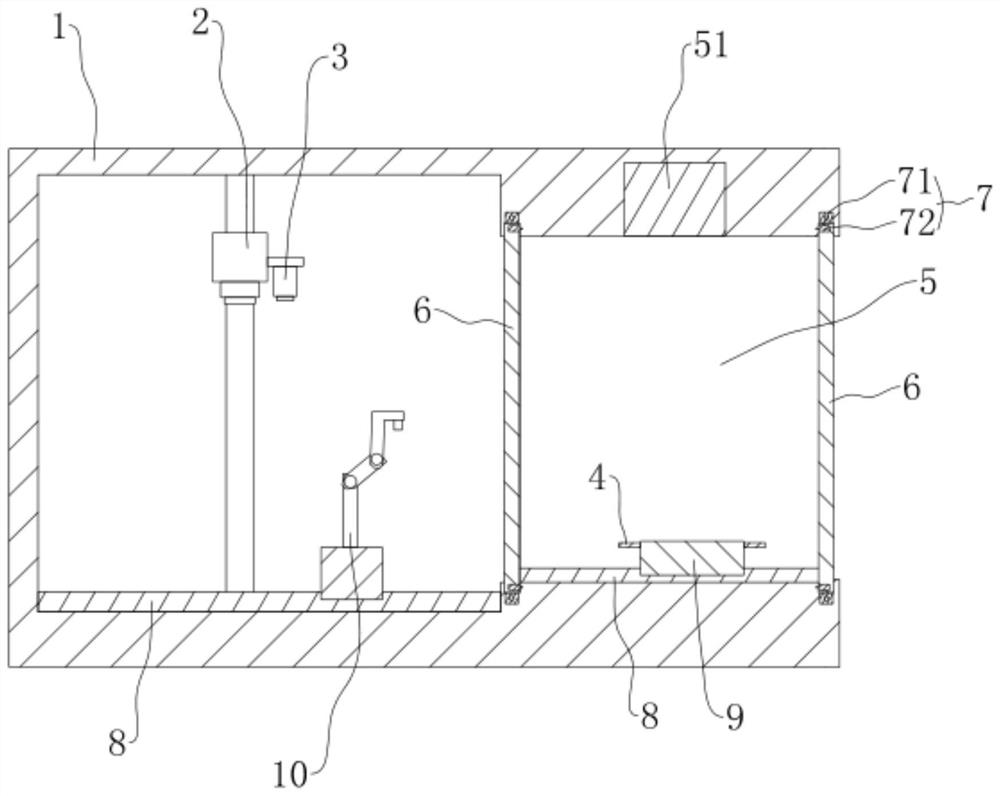

[0033] refer to Figure 1 to Figure 2 The non-destructive laser cleaning method is further explained.

[0034] A non-destructive laser cleaning method, such as figure 1 and figure 2 As shown, cleaning is performed by an airtight cleaning device. Specifically, the airtight cleaning device includes an airtight cleaning chamber 1 and a laser cleaning gun 2 arranged in the airtight cleaning chamber 1. The gun head of the laser cleaning gun 2 is provided with a tool for collecting workpieces to be cleaned. The image acquisition module 3 of the surface image, the outer wall of the closed cleaning chamber 1 is provided with a display for displaying the image acquired by the image acquisition module 3, so as to observe the surface image of the workpiece through the display in real time during cleaning.

[0035] like figure 1 and figure 2 As shown, the side wall of the airtight cleaning chamber 1 is provided with an inlet and outlet channel 5 for the workpiece to enter and exit, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com