Extreme rheological behavior composite material multi-layer co-extrusion continuous forming method and equipment

A multi-layer co-extrusion and composite material technology, applied in the field of polymer material molding, can solve the problems of difficult realization of multi-layer composite products with different viscosity, no material mixing function, and inability to form composite films in one step, and achieve good positive displacement transportation. Function, good dispersion and mixing effect, good dispersion and mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

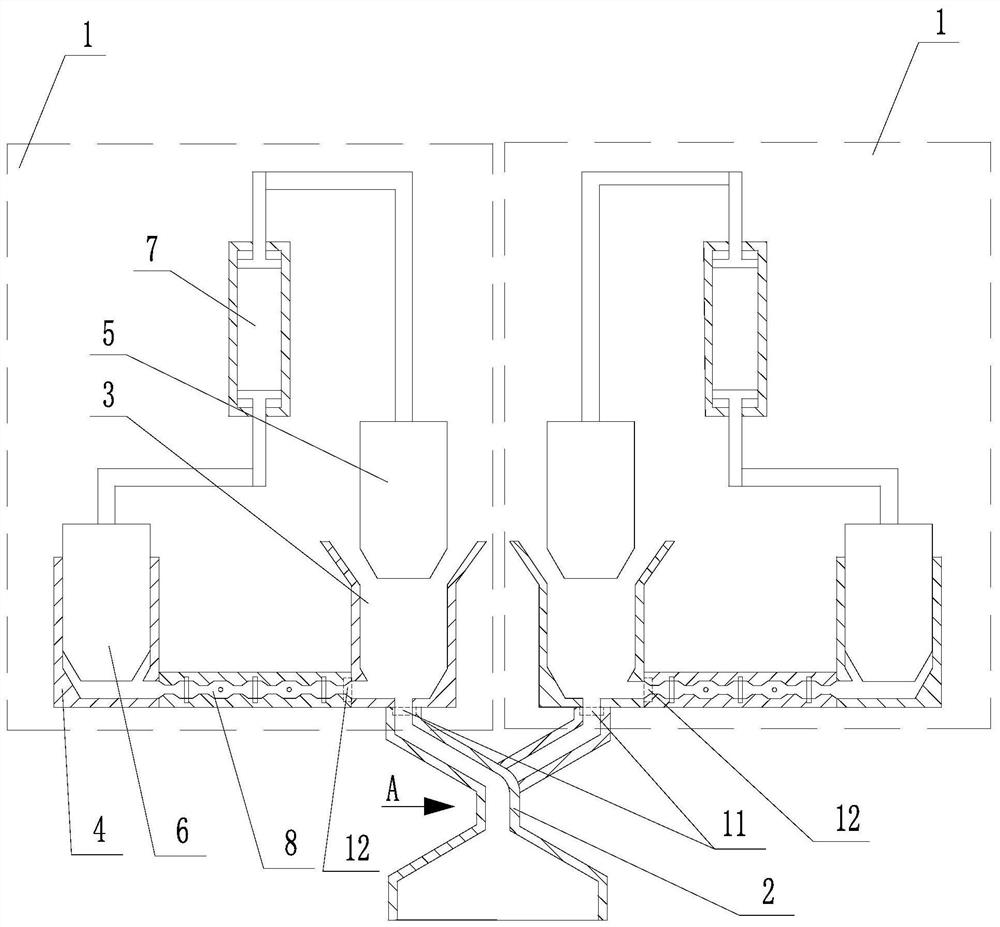

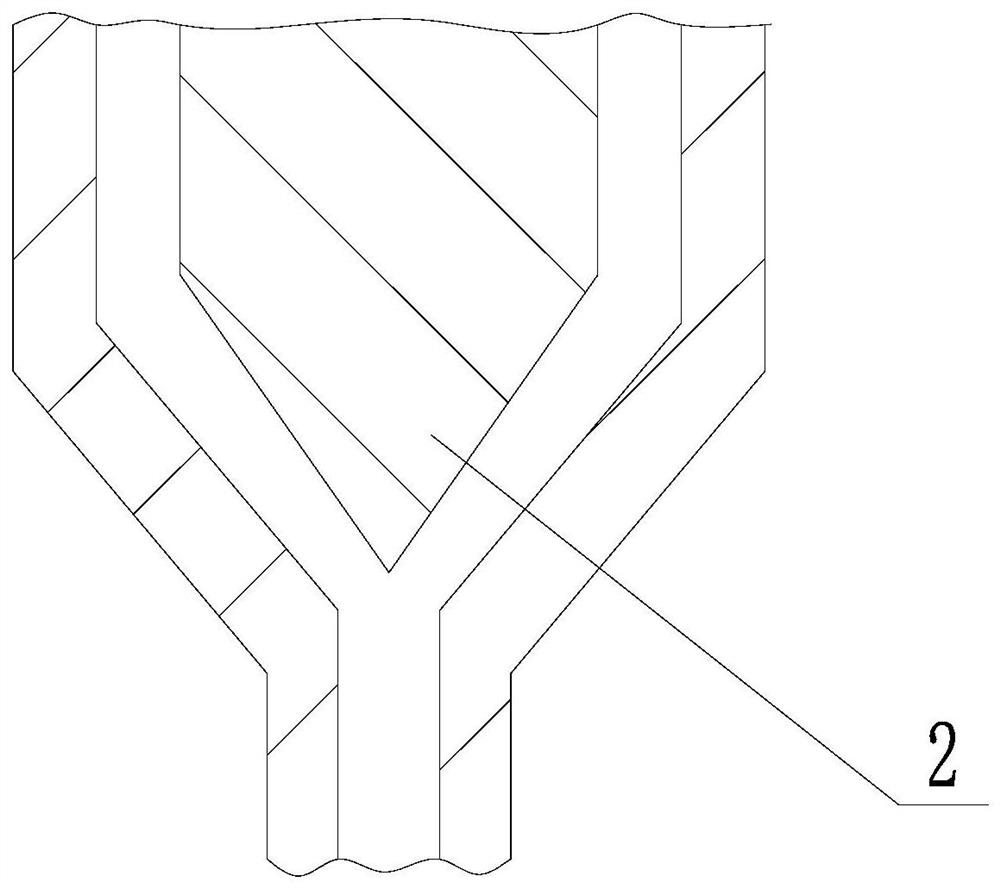

[0038] This embodiment is a multi-layer co-extrusion continuous molding method and equipment for composite materials with extreme rheological behavior, which are used for molding multi-layer sheets composed of different materials.

[0039] The extreme rheological behavior composite multi-layer co-extrusion continuous molding method is to use the flow field generated by the reciprocating cycle of the stretching chaotic unit to disperse and mix the materials with extreme rheological behavior; Carry out multi-layer co-extrusion continuous molding. Among them, materials with extreme rheological behavior are ultra-viscous materials (such as ultra-high molecular weight polymers such as ultra-high molecular weight polyethylene), medium-viscosity materials (such as polymers such as PE, PP) or ultra-thin materials (such as graphite and crude oil) mixed solutions, etc.).

[0040]In the stretching chaotic unit, the materials located at both ends of the stretching chaotic unit are altern...

Embodiment 2

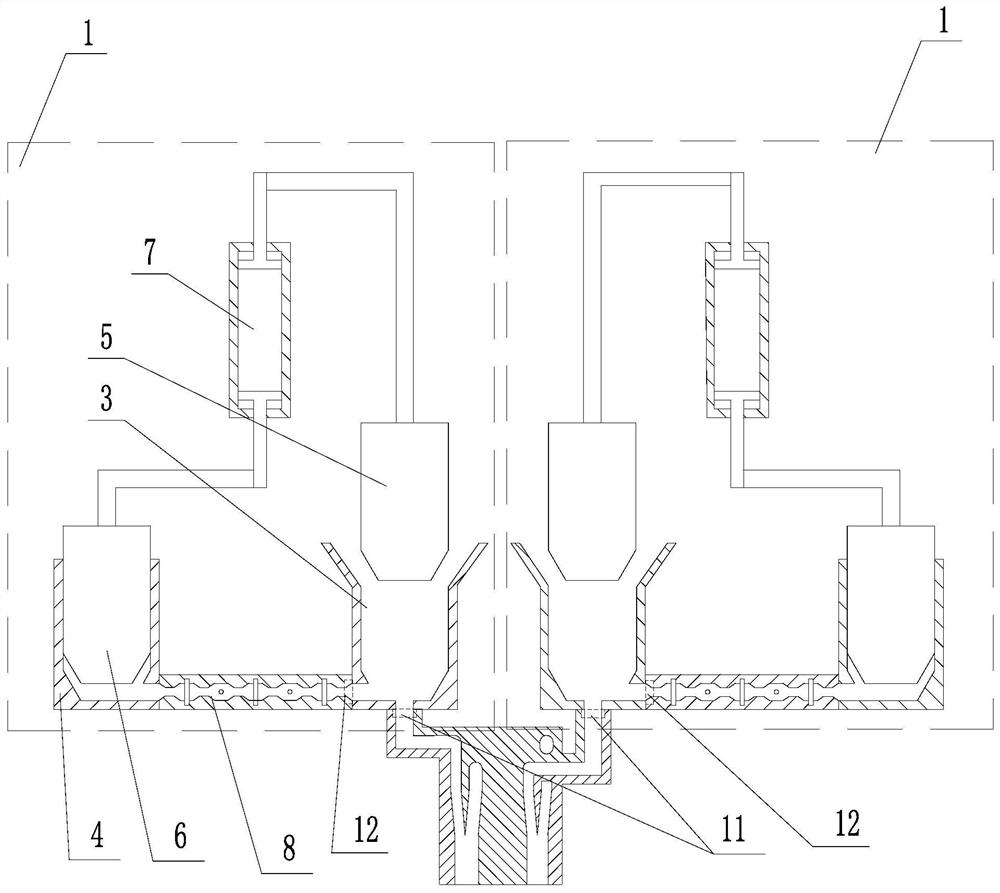

[0048] This embodiment is a multi-layer co-extrusion continuous molding method and equipment for composite materials with extreme rheological behavior, which are used for forming multi-layer pipes composed of different materials. Compared with Example 1, its difference is: as image 3 As shown, the structure of the multi-layer co-extrusion die in the co-extrusion device is different from that of Example 1, and the final product obtained by this device is a multi-layer pipe.

Embodiment 3

[0050] This embodiment is a multi-layer co-extrusion continuous molding method and equipment for composite materials with extreme rheological behavior, which are used for molding multi-layer sheets composed of different materials. Compared with Example 1, its difference is: as Figure 7 to Figure 9 As shown, the stretching chaotic unit includes multiple stretching and converging outer cylinders connected in sequence, each stretching and converging outer cylinder 9 is provided with a shunt pin 10, and a shunt pin is distributed in the same section of the stretching and converging outer cylinder, An included angle of 30°, 45°, 60° or 90° is formed between the shunt pins in any two adjacent sections, and the specific angle value of the included angle can be selected according to the actual situation of the equipment. The multi-section tensile convergence outer cylinder is connected to form a continuous inner cavity, and the cross section of the inner cavity shows a periodic chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com