Domestic sewage treatment process

A domestic sewage and treatment process technology, applied in the direction of biological water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of poor operation stability of sewage treatment system, unstable effluent quality, and low sewage treatment efficiency To achieve the effect of promoting the improvement of treatment efficiency, accelerating the enrichment and adsorption removal, and improving the quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

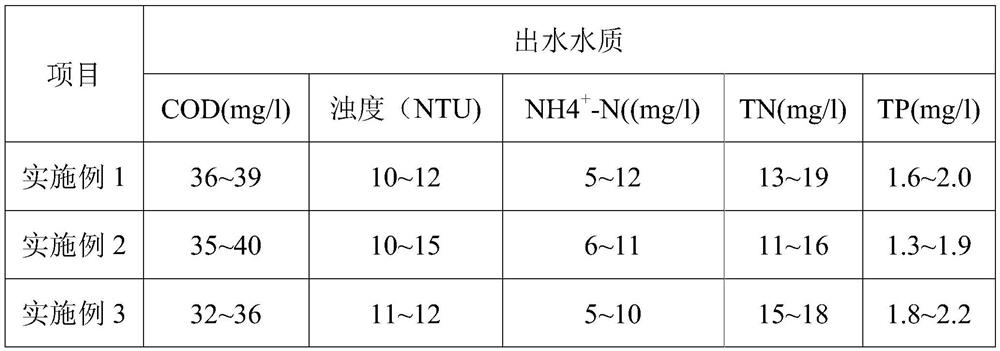

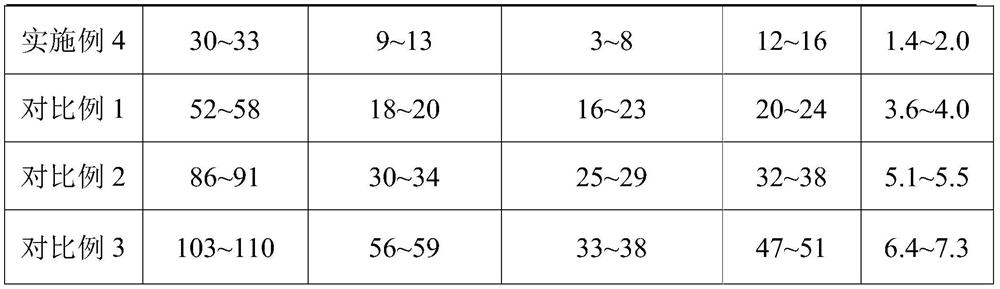

Examples

Embodiment 1

[0024] Embodiment 1-a kind of domestic sewage treatment process comprises the steps:

[0025] Step 1: Pretreatment, filter the domestic sewage through the grid well to remove large solid impurities in the sewage;

[0026] Step 2: Primary flocculation, put the domestic sewage in the primary flocculation tank, add flocculant A, the dosage is 18.5mg per liter of domestic sewage, make it react with the organic matter and suspended particles in the sewage for 15 minutes, and get the treatment Water I; The flocculant A comprises 30 parts of iron sulfate, 10 parts of aluminum sulfate, 3 parts of chitosan and 20 parts of cationic starch according to the ratio of parts by weight;

[0027] Step 3: Anaerobic primary degradation, the treated water I is subjected to anaerobic degradation reaction in the anaerobic reaction tank for 15 hours, and the biodegradable organic matter in the sewage is removed to obtain the treated water II;

[0028] Step 4: secondary flocculation, put the treated...

Embodiment 2

[0030] Embodiment 2-a kind of domestic sewage treatment process, comprises the steps:

[0031] Step 1: Pretreatment, filter the domestic sewage through the grid well to remove large solid impurities in the sewage;

[0032] Step 2: Primary flocculation, put the domestic sewage in the primary flocculation tank, add flocculant A, the dosage is 23.5mg per liter of domestic sewage, make it react with the organic matter and suspended particles in the sewage for 20 minutes, and get the treatment Water I; The flocculant A comprises 50 parts of ferric sulfate, 20 parts of aluminum sulfate, 5 parts of chitosan and 30 parts of cationic starch according to the ratio in parts by weight;

[0033] Step 3: Anaerobic primary degradation, the treated water I is subjected to anaerobic degradation reaction in the anaerobic reaction tank for 20 hours, and the biodegradable organic matter in the sewage is removed to obtain the treated water II;

[0034] Step 4: secondary flocculation, put the trea...

Embodiment 3

[0036] Embodiment 3-a kind of domestic sewage treatment process, comprises the steps:

[0037] Step 1: Pretreatment, filter the domestic sewage through the grid well to remove large solid impurities in the sewage;

[0038] Step 2: Primary flocculation, put the domestic sewage in the primary flocculation tank, add flocculant A, the dosage is 20.5mg per liter of domestic sewage, make it react with the organic matter and suspended particles in the sewage for 16 minutes, and get the treatment Water I; The flocculant A comprises 40 parts of ferric sulfate, 12 parts of aluminum sulfate, 4 parts of chitosan and 22 parts of cationic starch according to the ratio in parts by weight;

[0039] Step 3: Anaerobic primary degradation, the treated water I is subjected to anaerobic degradation reaction in an anaerobic reaction tank for 16 hours, and the biodegradable organic matter in the sewage is removed to obtain the treated water II;

[0040] Step 4: secondary flocculation, put the treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com