Pavement brick prepared from construction waste recycled aggregate and preparation process thereof

A technology of recycled aggregates and construction waste, applied in the field of building materials, can solve problems such as low strength levels, achieve the effects of reducing production costs, reducing environmental pollution, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

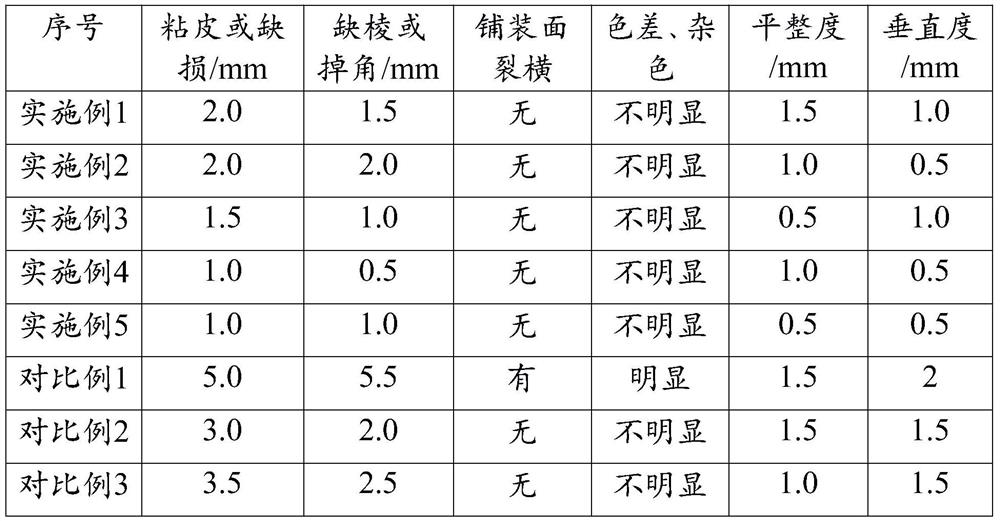

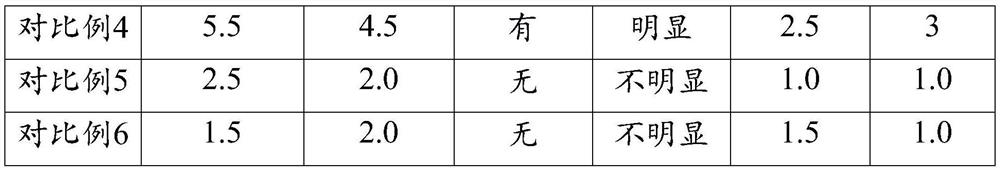

Examples

Embodiment 1

[0049] The utility model relates to a pavement brick prepared from construction waste recycled aggregate, which is composed of a surface layer and a bottom layer.

[0050] Wherein, the surface layer is made of the following raw materials in mass percentage: 25% of cement, 62% of tailing sand and 13% of water. Among them, the particle size of tailings sand is less than 5mm.

[0051] The bottom layer is made of the following raw materials in mass percentage: 12% of cement, 48% of brick-concrete mixed recycled aggregate, 26% of concrete recycled aggregate, 4% of mineral admixture, and 10% of water.

[0052] Among them, the mineral admixture is composed of 47% limestone powder, 33% natural pozzolan and 20% slag.

[0053] The particle size of the brick-concrete mixed recycled aggregate is less than 5mm, and the particle size of the concrete recycled aggregate is 3-8mm.

[0054] The total thickness of the above-mentioned paving bricks is 50mm, wherein the thickness of the surface ...

Embodiment 2

[0062] The utility model relates to a pavement brick prepared from construction waste recycled aggregate, which is composed of a surface layer and a bottom layer.

[0063] Wherein, the surface layer is made of the following raw materials in mass percentage: 22% of cement, 68% of tailing sand and 10% of water. Among them, the particle size of tailings sand is less than 5mm.

[0064] The bottom layer is made of the following raw materials in mass percentage: 14% of cement, 46% of brick-concrete mixed recycled aggregate, 29% of concrete recycled aggregate, 3% of mineral admixture, and 8% of water.

[0065] Among them, the mineral admixture is composed of 55% limestone powder, 31% natural pozzolan and 14% slag.

[0066] The particle size of the brick-concrete mixed recycled aggregate is less than 5mm, and the particle size of the concrete recycled aggregate is 3-8mm.

[0067] The total thickness of the above-mentioned paving bricks is 50mm, wherein the thickness of the surface l...

Embodiment 3

[0075] The utility model relates to a pavement brick prepared from construction waste recycled aggregate, which is composed of a surface layer and a bottom layer.

[0076] Wherein, the surface layer is made of the following raw materials in mass percentage: 29% of cement, 63% of tailing sand and 8% of water. Among them, the particle size of tailings sand is less than 5mm.

[0077] The bottom layer is made of the following raw materials in mass percentage: 15% of cement, 47% of brick-concrete mixed recycled aggregate, 25% of concrete recycled aggregate, 5% of mineral admixture, and 8% of water.

[0078] Among them, the mineral admixture is composed of 45% limestone powder, 34% natural pozzolan and 21% slag.

[0079] The particle size of the brick-concrete mixed recycled aggregate is less than 5mm, and the particle size of the concrete recycled aggregate is 3-8mm.

[0080] The total thickness of the above-mentioned paving bricks is 63mm, wherein the thickness of the surface la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com