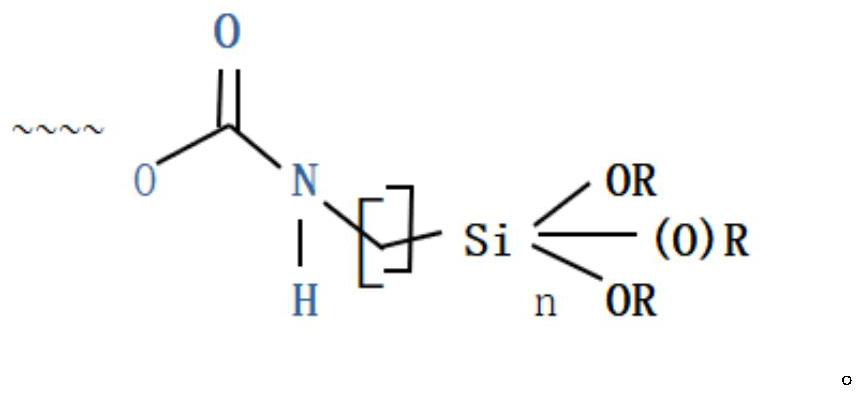

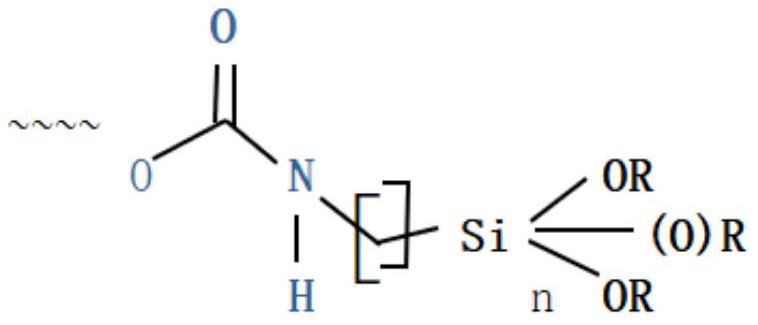

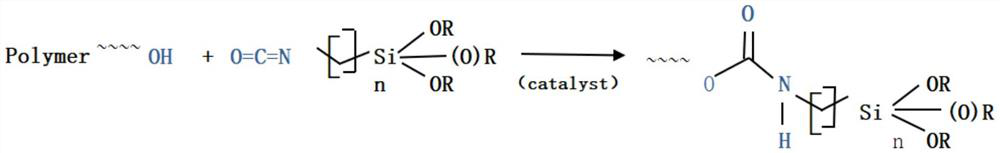

Silane modified polymer waterproof coating with zero solvent and high environmental protection performance and preparation method thereof

A silane-modified, waterproof coating technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of high drying degree of substrates, poor weather resistance, poor water resistance of coating films, etc. Good weather resistance, excellent water resistance, fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In a closed reaction kettle, add silane-modified polymer resin and start stirring, the mixer speed is 300 rpm; add water remover and light stabilizer and stir for 5 minutes, adjust the mixer speed to 600 rpm, and then add meteorological silica 1. Disperse aluminum hydroxide for 20 minutes with constant stirring speed, then add superfine calcium carbonate and disperse for 30 minutes. After the dispersion is uniform, the rotation speed is maintained at 600 rpm, slowly add the silane coupling agent, stir for 5 minutes, turn off the stirring, and defoam for 10 minutes under the vacuum pressure of -0.09~-0.1MPa to prepare a zero-solvent silane-terminated polymer waterproof coating.

[0031] The amount of each component described in the preparation method of the above-mentioned zero-solvent high-environmental protection performance silane-modified polymer waterproof coating is respectively: 35 parts of silane-modified polymer resin, 49 parts of calcium carbonate, 1 part of wat...

Embodiment 2

[0033] In a closed reaction kettle, add silane-modified polymer resin and start stirring, the mixer speed is 300 rpm; add water remover and light stabilizer and stir for 5 minutes, adjust the mixer speed to 600 rpm, and then add meteorological silica 1. Disperse aluminum hydroxide for 20 minutes with constant stirring speed, then add superfine calcium carbonate and disperse for 30 minutes. After the dispersion is uniform, the rotation speed is maintained at 600 rpm, slowly add the silane coupling agent, stir for 5 minutes, turn off the stirring, and defoam for 10 minutes under the vacuum pressure of -0.09~-0.1MPa to prepare a zero-solvent silane-terminated polymer waterproof coating.

[0034] The amount of each component described in the preparation method of the above-mentioned zero-solvent high-environmental protection performance silane-modified polymer waterproof coating is respectively: 35 parts of silane-modified polymer resin, 30 parts of nano-calcium, 3 parts of water-r...

Embodiment 3

[0036] In a closed reaction kettle, add silane-modified polymer resin and start stirring, the mixer speed is 300 rpm; add water remover and light stabilizer and stir for 5 minutes, adjust the mixer speed to 600 rpm, and then add meteorological silica 1. Disperse aluminum hydroxide for 20 minutes with constant stirring speed, then add superfine calcium carbonate and disperse for 30 minutes. After the dispersion is uniform, the rotation speed is maintained at 600 rpm, slowly add the silane coupling agent, stir for 5 minutes, turn off the stirring, and defoam for 10 minutes under the vacuum pressure of -0.09~-0.1MPa to prepare a zero-solvent silane-terminated polymer waterproof coating.

[0037]The dosage of each component described in the preparation method of the above-mentioned silane-modified polymer waterproof coating with zero solvent and high environmental performance is: 20 parts of silane-modified polymer resin, 40 parts of nano-calcium, 1 part of water-removing agent, li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com