Unqualified fresh steam condensate water waste heat utilization and secondary recovery method

A technology for secondary recovery and condensed water, applied in steam/steam condensers, heat exchangers, heat exchanger types, etc., can solve problems such as waste and heat loss, reduce steam volume, avoid losses and waste, and save energy cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

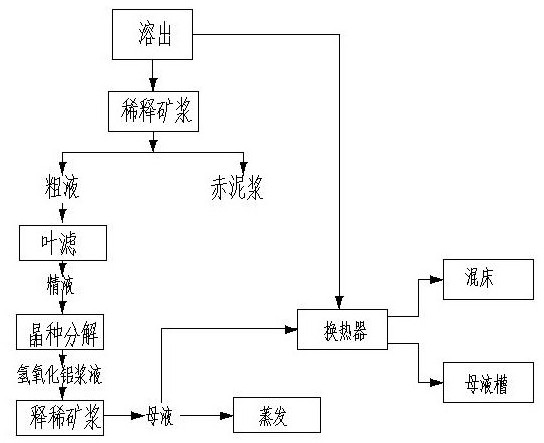

Method used

Image

Examples

Embodiment

[0013] In this embodiment, the production capacity of 800,000 tons of alumina in a certain factory is taken as an example.

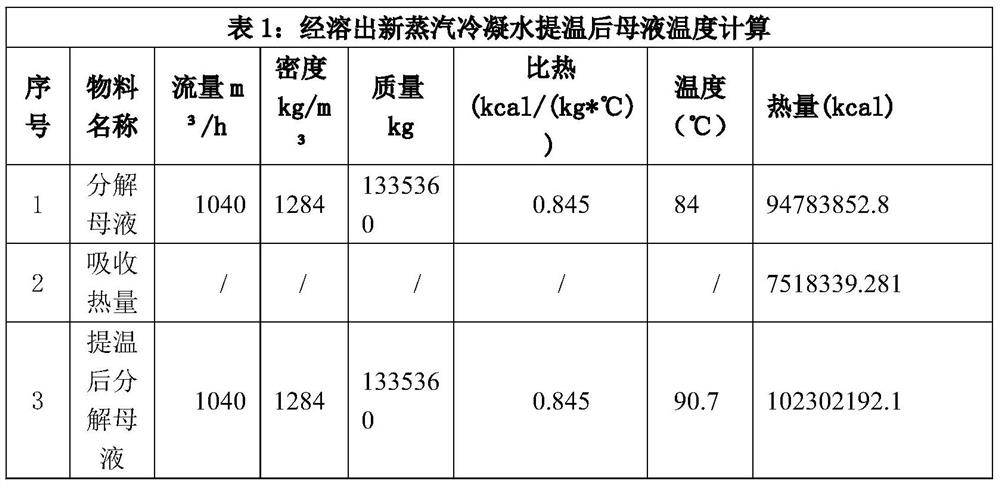

[0014] The decomposed mother liquid is heated through the shell and tube heat exchanger to form the evaporated raw liquid, and the average amount of decomposed cold mother liquid is 1040m 3 / h, the temperature of the evaporating stock solution is 84°C; the temperature of the whole stock solution can be increased to 90.7°C after stripping out unqualified new steam condensed water to heat up the temperature (see Table 1)

[0015]

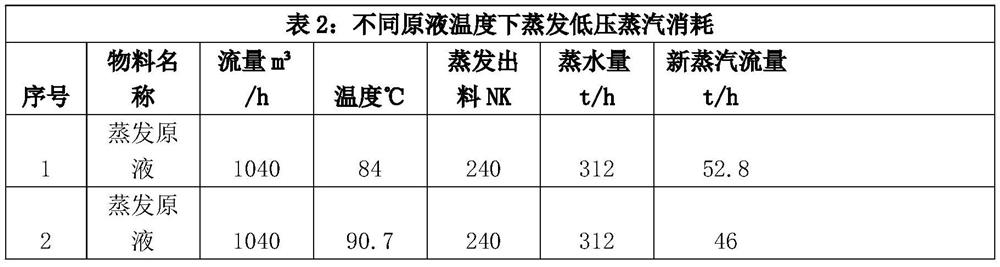

[0016] According to the calculation of evaporation heat balance, when the temperature of the evaporation stock solution is 90.7°C, the new steam consumption is 6.8t / h less than that of the stock solution temperature of 84°C (see Table 2).

[0017]

[0018] At the same time, chemical water treatment mainly removes calcium, magnesium plasma and suspended solids in raw water, and unqualified dissolution of new steam condenses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com