Inclined U-shaped chiral structure and preparation method thereof

A chiral structure, U-shaped technology, applied in the field of tilted U-shaped chiral structure and its preparation, can solve the problems of complex three-dimensional chiral nanostructure, high input cost, complicated process, etc., achieve excellent field enhancement effect, reduce Loss, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

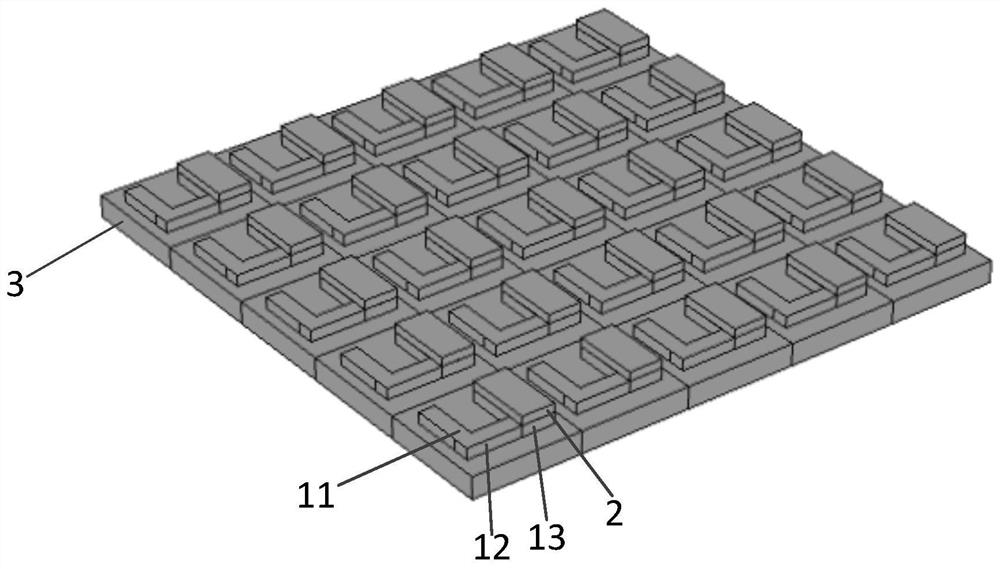

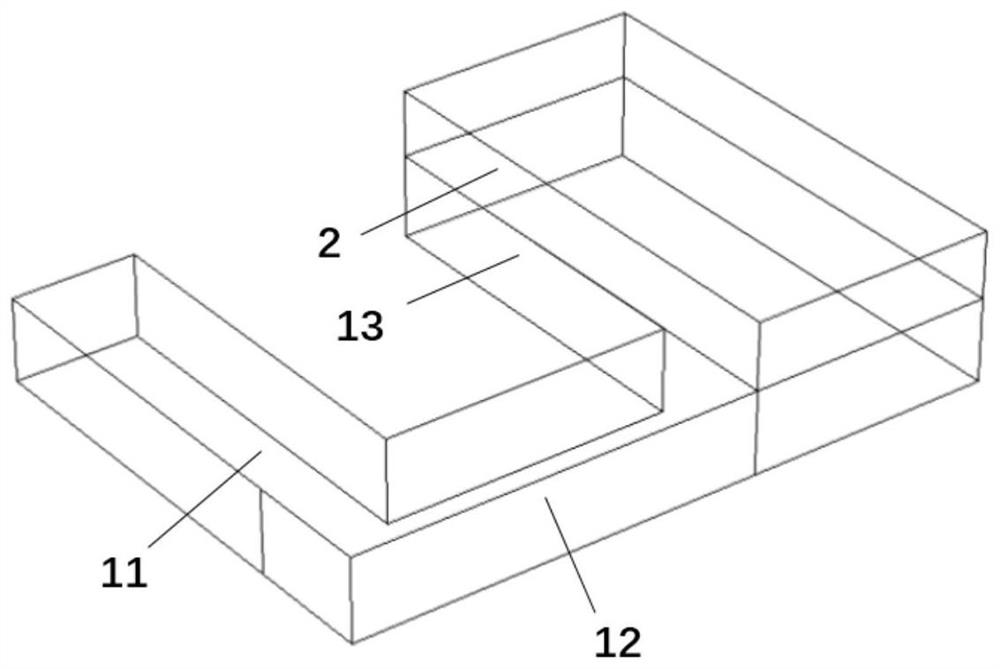

[0039] The present application provides a tilted U-shaped chiral structure, which includes: a substrate 3 and a plurality of chiral units periodically arranged on the substrate 3, each chiral unit includes a first rectangular bar 11, a second rectangular bar 12, a third Rectangular strip 13 and raised portion 2, the two ends of the second rectangular strip 12 are respectively connected with the first rectangular strip 11 and the third rectangular strip 13, the first rectangular strip 11 and the third rectangular strip 13 are parallel to each other, and the first rectangular strip The strip 11 and the third rectangular strip 13 are all perpendicular to the second rectangular strip 12, the first rectangular strip 11, the second rectangular strip 12 and the third rectangular strip 13 form a "U"-shaped structure, and the protrusion 2 is arranged on the third rectangular strip. The strip 13 is away from the side of the base 3 , and the projections of the raised portion 2 and the thi...

Embodiment 2

[0047] Optionally, the width of the first rectangular strip 11 is equal to the width of the second rectangular strip 12, and the thicknesses of the first rectangular strip 11, the second rectangular strip 12, and the third rectangular strip 13 perpendicular to the direction of the base 3 are equal.

[0048] Optionally, the width of the third rectangular strip 13 is greater than the widths of the first rectangular strip 11 and the second rectangular strip 12 , and the lengths of the first rectangular strip 11 , the second rectangular strip 12 and the third rectangular strip 13 increase sequentially.

[0049] Optionally, the first rectangular strip 11 and the second rectangular strip 12 have a width of 150 nanometers, the third rectangular strip 13 has a width of 300 nanometers, the first rectangular strip 11 has a length of 450 nanometers, and the second rectangular strip 12 has a width of 300 nanometers. The length is 500 nanometers, the length of the third rectangular strip 13...

Embodiment 3

[0054] Based on Embodiment 1, this embodiment of the present application provides another inclined U-shaped structure. It is basically the same as Embodiment 1, the only difference is that the inclined U-shaped structure is composed of two different materials.

[0055] Optionally, the material of the pad portion is silicon, and the material of the protruding portion 2 is a noble metal material. That is to say, the materials of the first rectangular strip 11 , the second rectangular strip 12 and the third rectangular strip 13 are all silicon, and the material of the protruding portion 2 is noble metal material.

[0056] Optionally, the precious metal material is any one of gold, silver and copper. Preferably, the structure is made of silver. The price is cheaper than gold, which can save experimental costs.

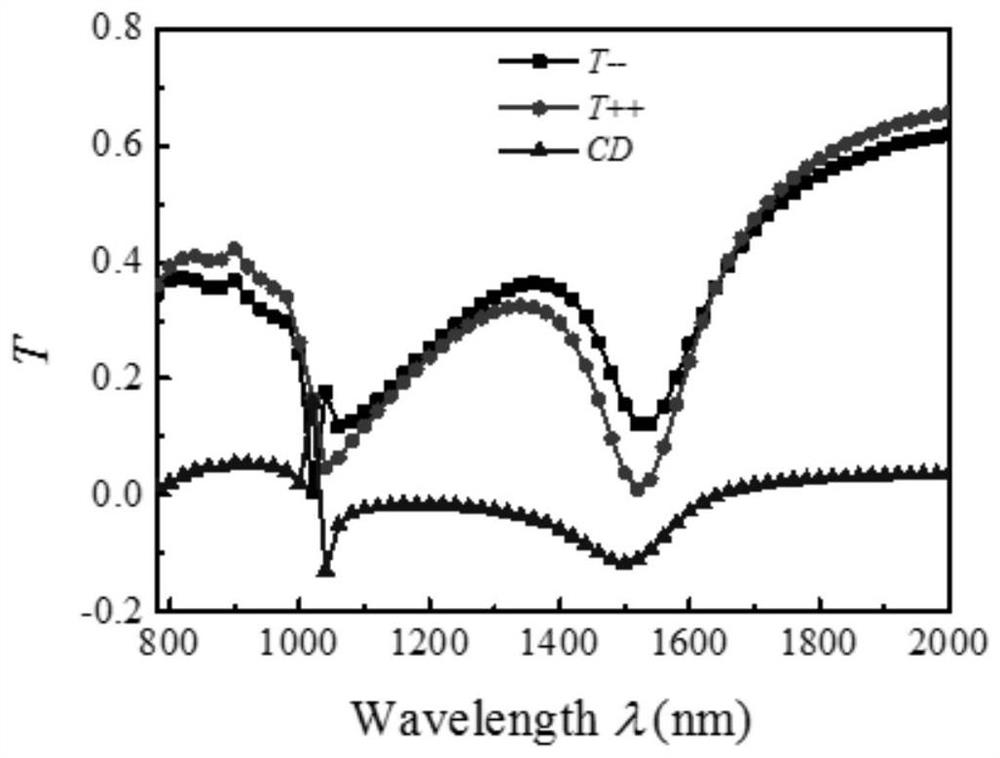

[0057] For the convenience of explanation, the calculation and simulation experiment of the tilted U-shaped chiral structure is carried out here by using the three-dime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com