Method for calculating tapping time of steelmaking converter

A calculation method and technology of a steel-making converter, which are applied in the field of iron and steel metallurgy, and can solve the problem of not publicly reporting the tapping time of the steel-making converter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

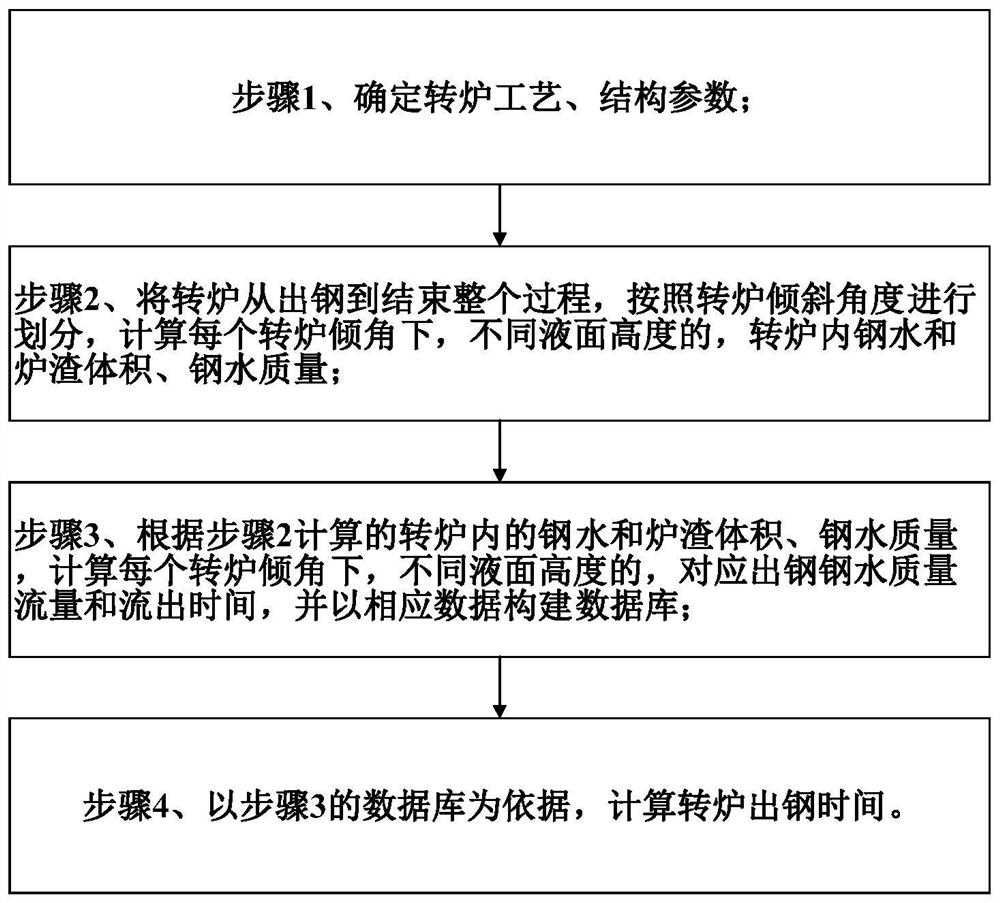

[0046] In an embodiment of the present invention, a method for calculating the tapping time of a steelmaking converter, such as figure 1 shown, including the following steps:

[0047] Step 1. According to the actual steelmaking converter structure and process conditions, determine the converter furnace type and structure size, as well as the converter tapping tilting mechanism type, working characteristics and speed range.

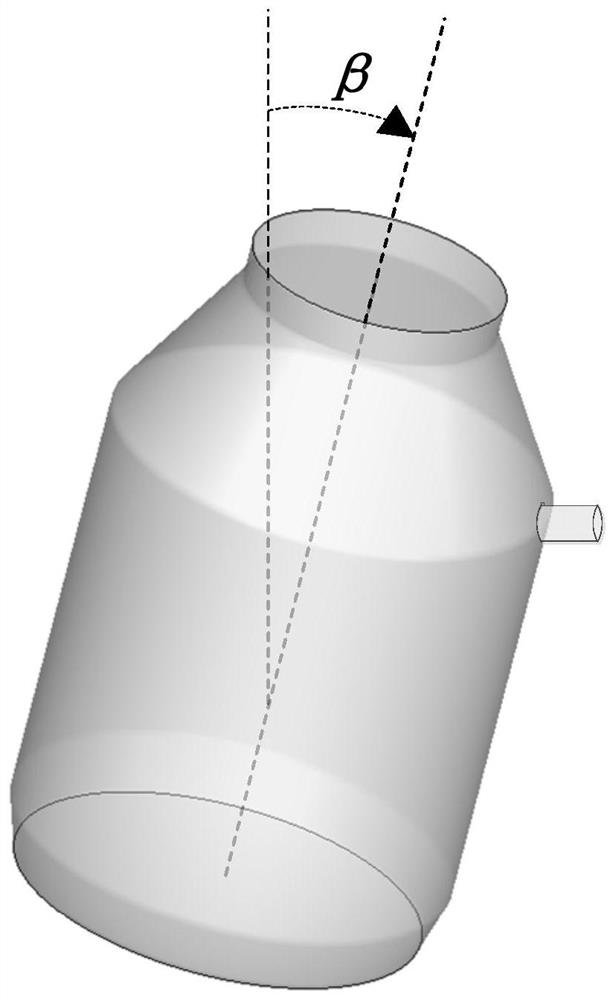

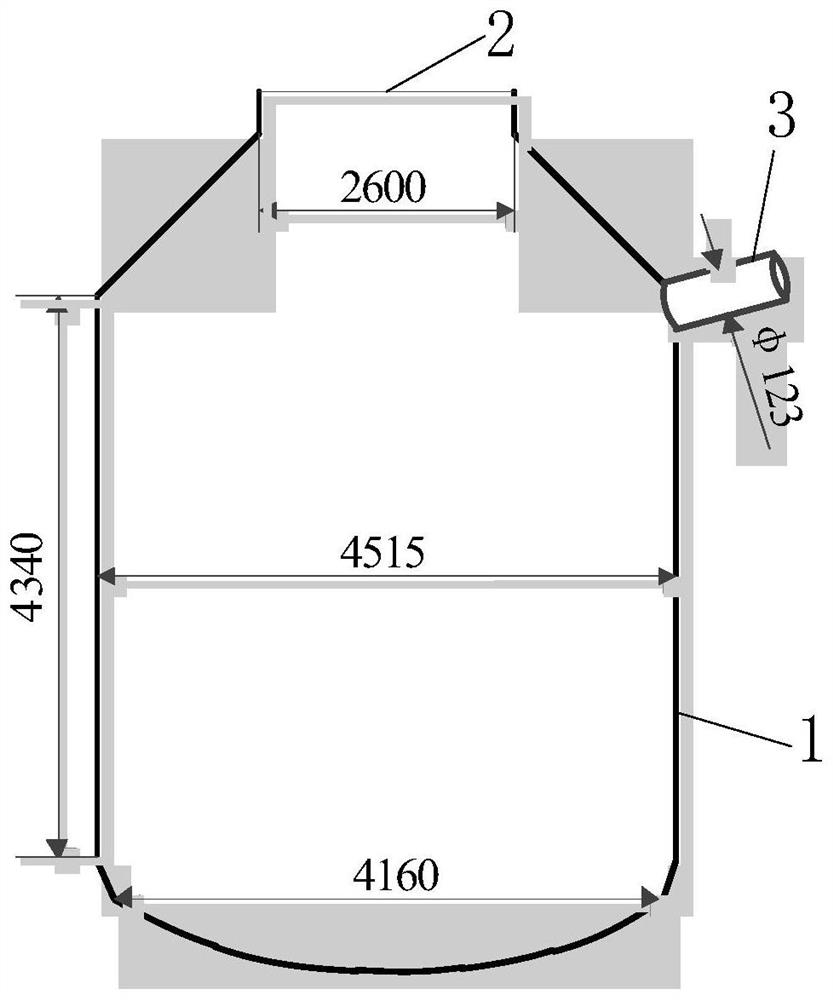

[0048] The embodiment of the present invention is a 120t cone-spherical converter, and its internal structure schematic diagram is as follows figure 2 As shown, β is the inclination angle of the converter, and the main structural parameters of the converter are as follows image 3 As shown, the inner diameter of converter shaft 1 is 4515mm, the diameter of furnace mouth 2 is 2600mm, and the inner diameter of tapping hole 3 is 123mm. The converter adopts a suspended tilting mechanism, and the entire transmission device is on the trunnion, especially the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com