Electroluminescent device, preparation method thereof and display device

A technology of electroluminescent devices and light-emitting layers, which is applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve problems such as limiting the performance of electroluminescent devices, large work function, and restricting the effective injection and transmission of electrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

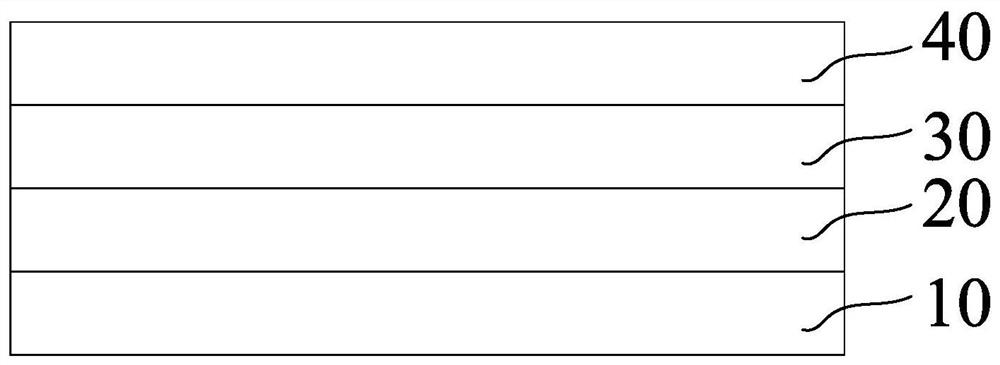

[0062] The embodiment of the present invention also provides a method for preparing an electroluminescent device, the electroluminescent device has an inverted structure, and the preparation method includes:

[0063] forming a cathode layer 10 on the substrate;

[0064] Forming the electronic functional layer 20 on the cathode layer 10, wherein the steps of forming the electronic functional layer 20 on the cathode layer 10 are:

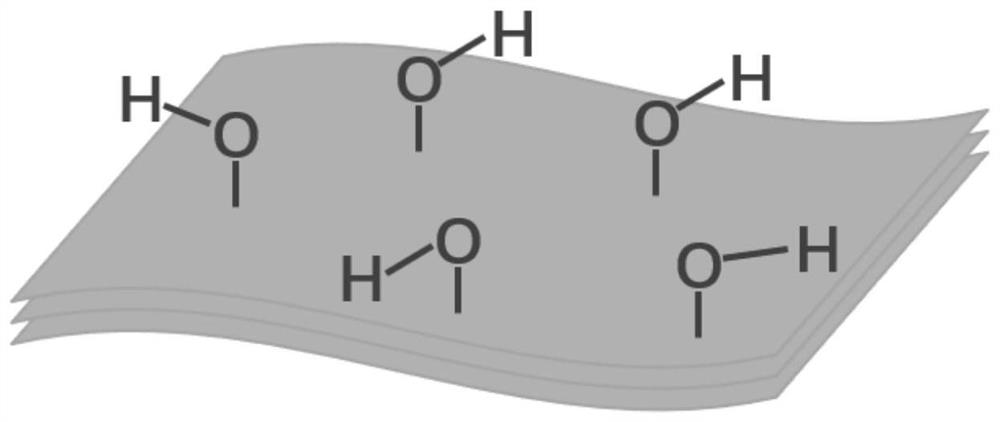

[0065] Provided is a mixed system comprising a functional material for transporting and / or injecting electrons, a hydroxyl-modified two-dimensional layered nanomaterial, and a solvent, the work function of the hydroxyl-modified two-dimensional layered nanomaterial being smaller than that of the functional material function;

[0066] depositing said hybrid system on said cathode layer 10; and

[0067] The solvent in the mixed system is removed.

[0068] In one of the embodiments, the preparation method of the electroluminescent device includes:

[...

Embodiment 1

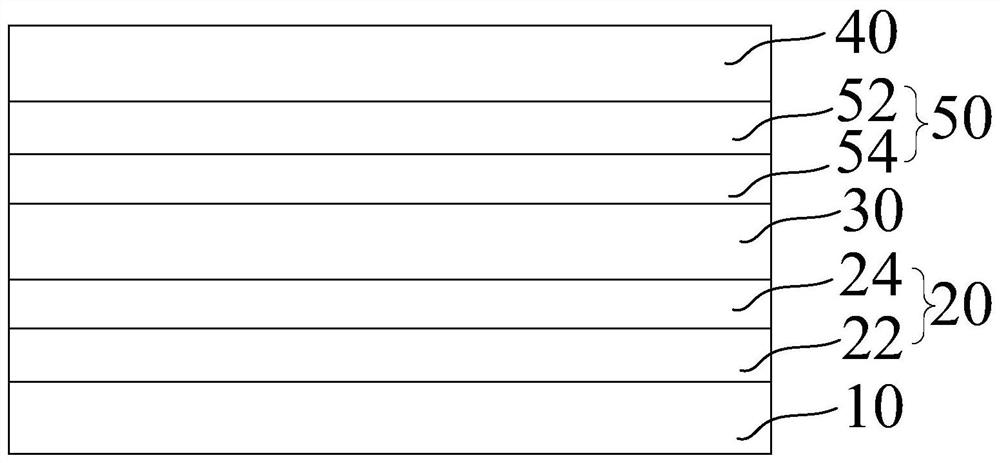

[0092] (1) The transparent conductive film ITO is used as the cathode layer 10 with a thickness of 50 nm.

[0093] (2) The electronic functional material SnO 2 and hydroxyl-modified two-dimensional layered nanomaterials Ti 4 N 3 (OH) 2 According to the mass ratio of 0.7:0.3 dispersed in water and ethanol mixed liquid to obtain electron transport layer 24 mixed system. The mixed system of the electron transport layer 24 was coated on the cathode layer 10 with a solution, and the solvent was removed to obtain the electron transport layer 24 with a thickness of 50 nm.

[0094] (3) Deposit ZnCdS / ZnS quantum dot material as the quantum dot light-emitting layer 30 on the electron transport layer 24 by solution method, with a thickness of 25 nm.

[0095] (4) Depositing CPB as the hole transport layer 54 on the quantum dot light-emitting layer 30 by evaporation method, with a thickness of 40 nm.

[0096] (5) Deposit HAT-CN as the hole injection layer 52 on the hole transport laye...

Embodiment 2

[0099] (1) The transparent conductive film ITO is used as the cathode layer 10 with a thickness of 50 nm.

[0100] (2) The two-dimensional layered nanomaterial Ti modified by the electronic functional material ZnO and hydroxyl groups 4 N 3 (OH) 2 According to the mass ratio of 0.8:0.2 dispersed in water and ethanol mixed liquid to obtain electron transport layer 24 mixed system. The mixed system of the electron transport layer 24 was coated on the cathode layer 10 with a solution, and the solvent was removed to obtain the electron transport layer 24 with a thickness of 60 nm.

[0101] (3) Deposit ZnCdS / ZnS quantum dot material on the electron transport layer 24 as the quantum dot light-emitting layer 30 with a thickness of 30 nm by using a solution method.

[0102] (4) Deposit TCTA as the hole transport layer 54 on the quantum dot light-emitting layer 30 by evaporation method, with a thickness of 30 nm.

[0103] (5) Deposit MoO on the hole transport layer 54 by vapor depos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron work function | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com