Membrane electrode assembly production quality rapid sampling inspection method

A membrane electrode assembly, production quality technology, applied to electrical components, measurement of electrical variables, electrochemical generators, etc., can solve the quality control requirements that cannot truly reflect the performance and life of membrane electrode assemblies, and test methods cannot adapt to mass production And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

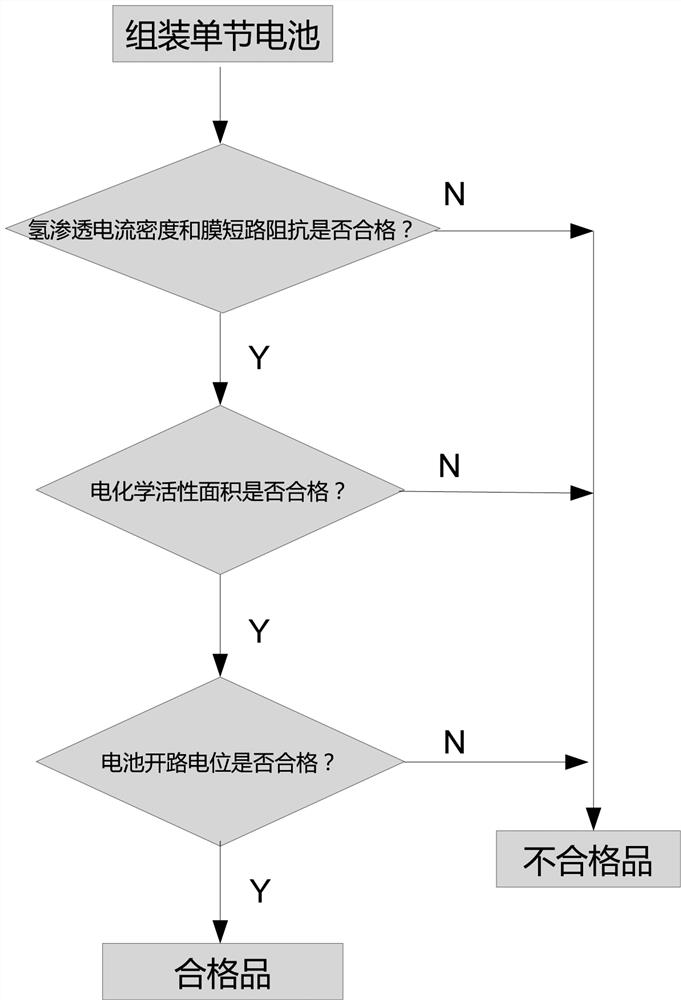

[0038] refer to figure 1 As shown, this embodiment is a rapid sampling method for the production quality of membrane electrode assemblies, including the following steps:

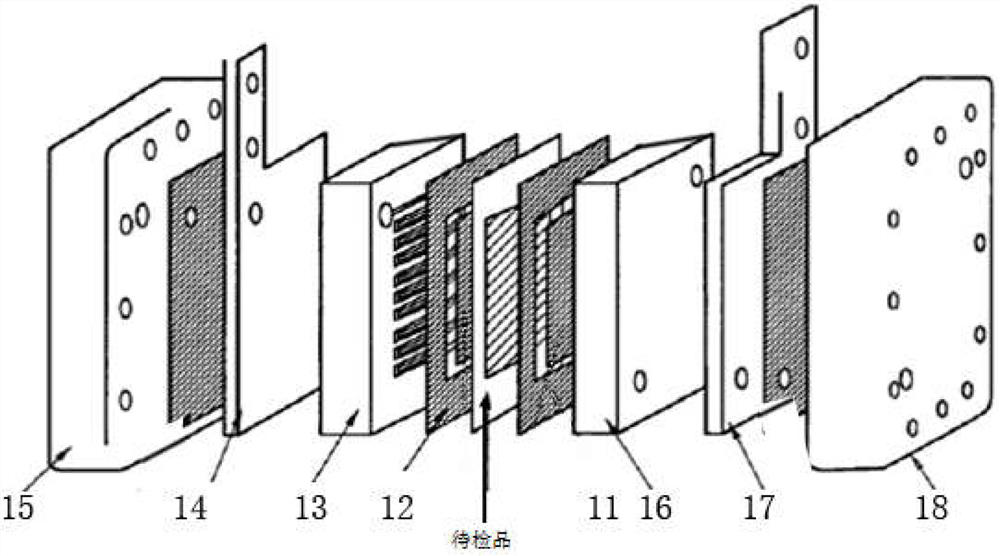

[0039] In step 1, the products to be inspected are taken out from the produced membrane electrode assemblies according to the batch sampling inspection requirements. Cooperate with the plate clamping tool to assemble a single fuel cell according to the assembly relationship, wherein the plate clamping tool includes cathode electrode sheet, cathode seal, cathode flow field plate, anode seal, anode flow field plate, anode electrode sheet and necessary The fasteners, the surface of the cathode electrode sheet and the anode electrode sheet are attached with a 2nm gold film by vacuum evaporation, and the above components are assembled through the stress of 10% compression rate in the active area of the membrane electrode. After assembly, it is connected to a single fuel cell detection device, which includes an...

Embodiment 2

[0044] This embodiment is a method for rapid sampling inspection of the production quality of membrane electrode assemblies, including the following steps:

[0045] In step 1, the products to be inspected are taken out from the produced membrane electrode assemblies according to the batch sampling inspection requirements. Cooperate with the plate clamping tool to assemble a single fuel cell according to the assembly relationship, wherein the plate clamping tool includes cathode electrode sheet, cathode seal, cathode flow field plate, anode seal, anode flow field plate, anode electrode sheet and necessary The fasteners, the surface of the cathode electrode sheet and the anode electrode sheet are attached with a 2nm gold film by vacuum evaporation, and the above components are assembled through the stress of 10% compression rate in the active area of the membrane electrode. After assembly, it is connected to a single fuel cell detection device, which includes an integrated con...

Embodiment 3

[0049] This embodiment is a method for rapid sampling inspection of the production quality of membrane electrode assemblies, which includes the following steps: Step 1, taking out the products to be inspected from the produced membrane electrode assemblies according to the batch sampling inspection requirements. Cooperate with the plate clamping tool to assemble a single fuel cell according to the assembly relationship, wherein the plate clamping tool includes cathode electrode sheet, cathode seal, cathode flow field plate, anode seal, anode flow field plate, anode electrode sheet and necessary The fasteners, the surface of the cathode electrode sheet and the anode electrode sheet are attached with a 2nm gold film by vacuum evaporation, and the above components are assembled through the stress of 10% compression rate in the active area of the membrane electrode. After assembly, it is connected to a single fuel cell detection device, which includes an integrated control unit, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com