Processing technology of organic green tea leaves

A processing technology, a technology for green tea leaves, applied in the direction of tea treatment before extraction, etc., can solve the problems of low extraction rate of tea content, and achieve the effect of improving the content of water extract and the uniformity of water content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

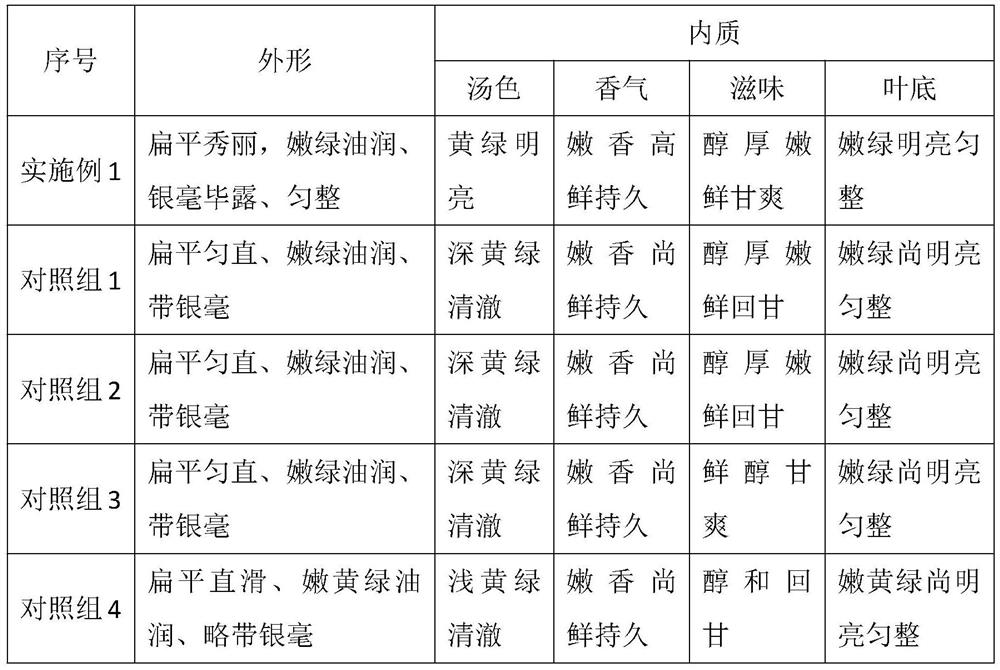

Examples

Embodiment 1

[0032] A kind of processing technique of organic green tea, is characterized in that: comprise the following steps:

[0033] 1) Picking: picking young buds and leaves, the standard is a single bud or one bud and one leaf at the beginning of development;

[0034] 2) Green spreading: Cut the picked fresh leaves into 2-3cm long segments, and then spread them on the dustpan with a leaf thickness of 1-1.5cm. 4 hours, turning 1 to 2 times in the middle, until the fresh leaves lose part of the water, the surface of the fresh leaves loses luster, until the water content is ≤85%;

[0035] 3) Finishing: the green tea leaves after being greened are finished with a roller fixing machine, the fixing temperature is 180°C, and the time is 4 minutes. The 6CST060 type roller fixing machine is used for finishing, and the speed of the fixing machine is set at 45 rpm;

[0036] 4) Spreading and airing: After the green leaves are cooled to 18-20°C, put them into bamboo or wooden tea storage contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com