A Method to Solve Conical Evaporator Salt Deposition

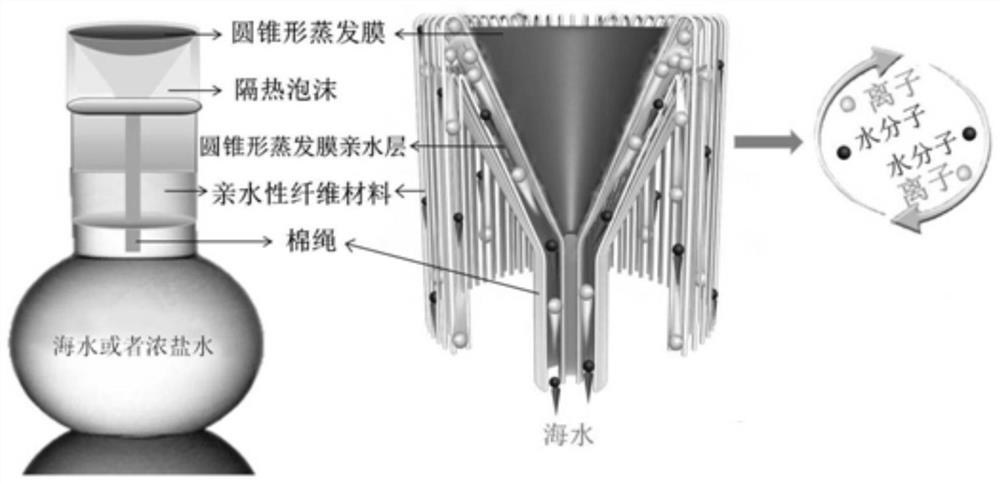

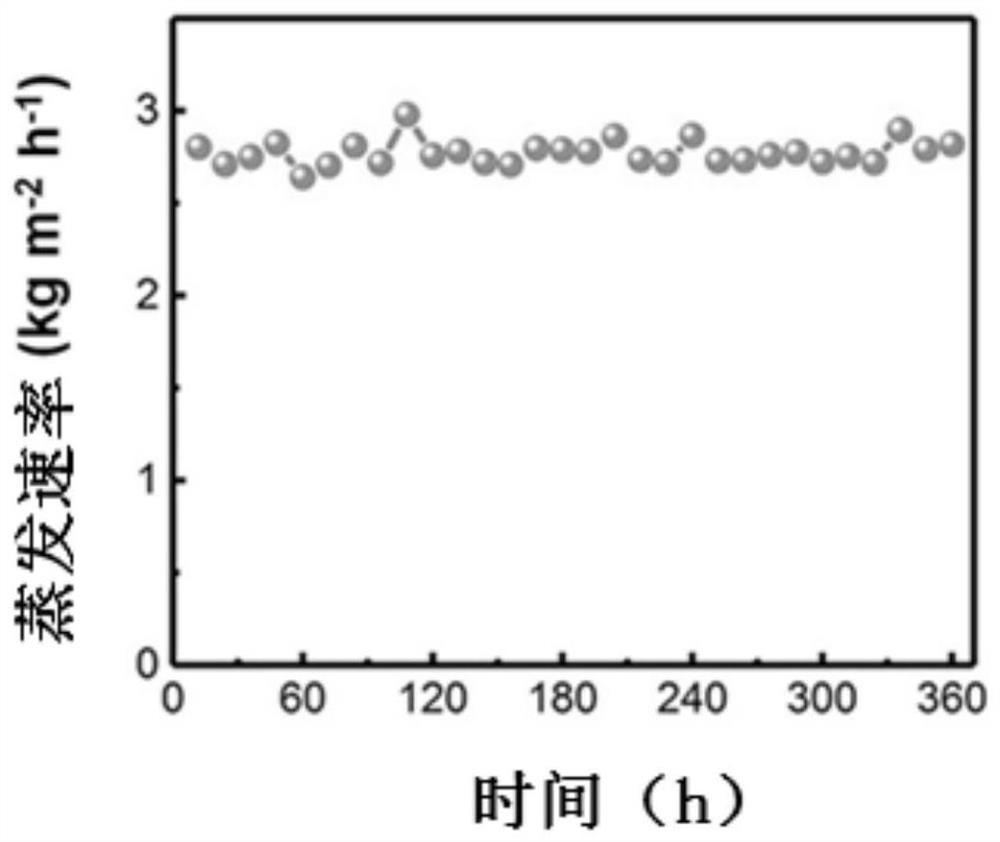

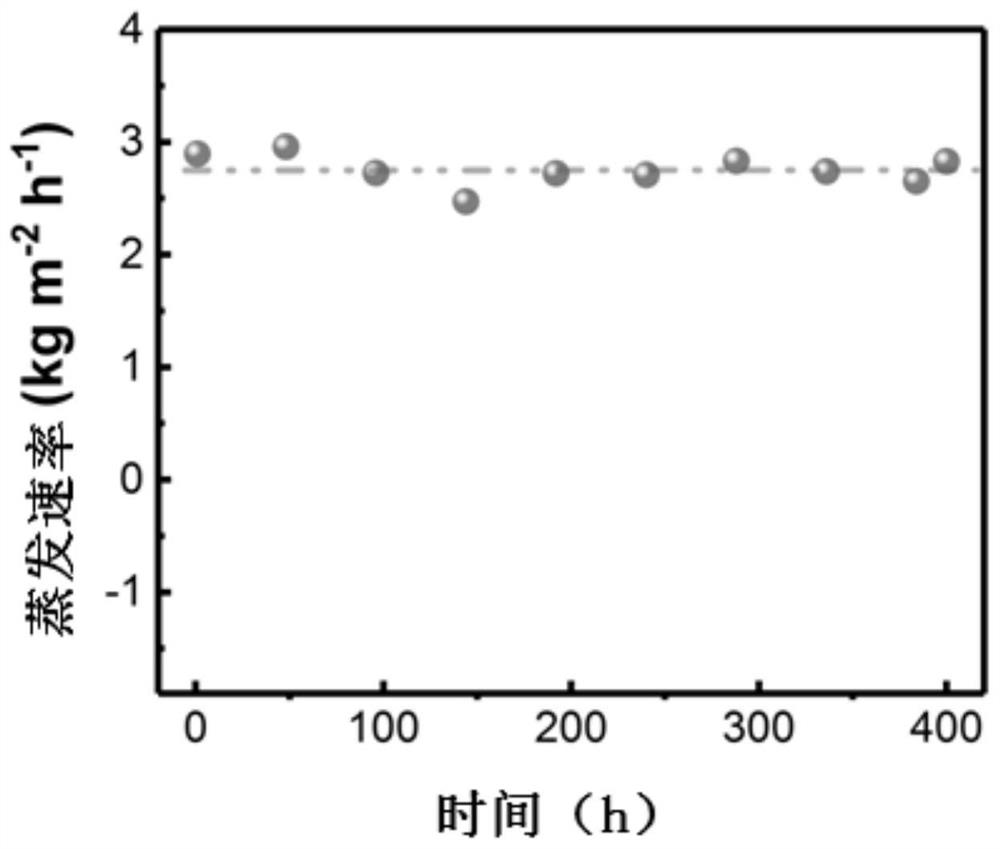

A conical, salt deposition technology, applied in the field of solar seawater desalination, can solve the problems of declining evaporation rate, inability to realize long-term continuous and stable operation of seawater desalination, etc. anti-salt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Specific implementation mode one: a kind of method for solving the salt deposition of conical evaporator in this implementation mode is completed according to the following steps:

[0023] 1. Evenly distribute the superhydrophobic light-to-heat conversion material on one surface of the hydrophilic support substrate to obtain a light-to-heat conversion film, and then fold the light-to-heat conversion film into Conical shape to obtain a conical light-to-heat conversion film;

[0024] 2. Process a conical groove on the upper end surface of the cylindrical heat insulating device, and process a through hole along the axial direction at the center of the bottom of the conical groove, and then insert one end of a hydrophilic water guiding device from the The upper end of the through hole extends until it is exposed from the lower end of the through hole, the other end of the hydrophilic water guiding device stays at the center of the bottom of the conical groove, and then the ...

specific Embodiment approach 2

[0029] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the superhydrophobic light-to-heat conversion material described in step 1 is graphene, carbon nanotubes, carbon black, graphite, molybdenum carbide@carbon, SiO 2 and one or more of polymer copolymers.

[0030] Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the hydrophilic support substrate described in step one is one of filter paper, non-woven fabric, cotton net, cloth strip and microporous membrane or several.

[0032] Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com