Riverway sludge-based engineering soil and preparation method thereof

A technology of river silt and engineering soil, which is applied in the field of river silt-based engineering soil and its preparation, can solve the problems that engineering soil cannot meet the engineering soil mechanical index requirements, high drying cost, high production cost, etc., and achieve the reduction of solid waste landfill and Outbound processing capacity, low cost of raw materials, and the effect of improving compaction and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

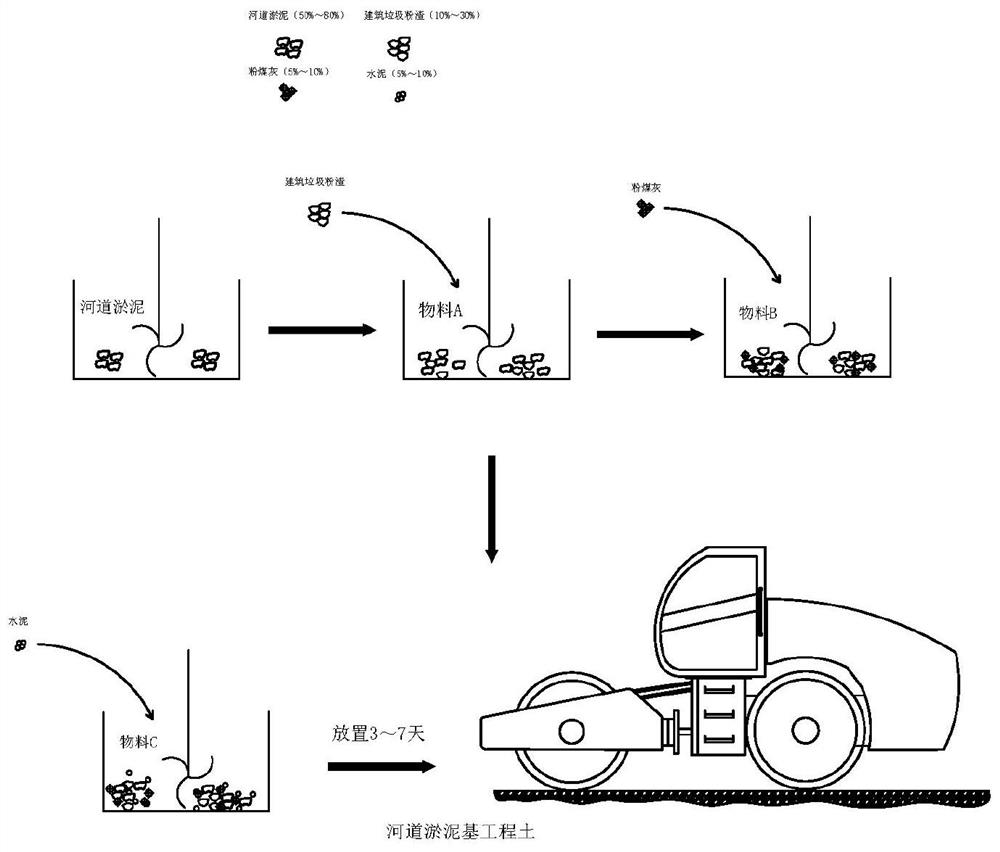

[0031] A kind of river course silt-based engineering soil, its preparation method comprises the steps:

[0032] 1) The raw materials are weighed, the components and their dosage conditions are: 800kg of river silt (dried for 4 days, moisture content 28%), 100kg of construction waste slag, 50kg of fly ash, 50kg of cement, and a water-cement ratio of 0.2;

[0033] 2) Place the weighed river silt particles and construction waste slag in the mixing bin, and after stirring for 60 seconds, add fly ash in the stirring state, and stir for 30 seconds; then add cement in the stirring state, and stir for 30 seconds to obtain the mixture ;

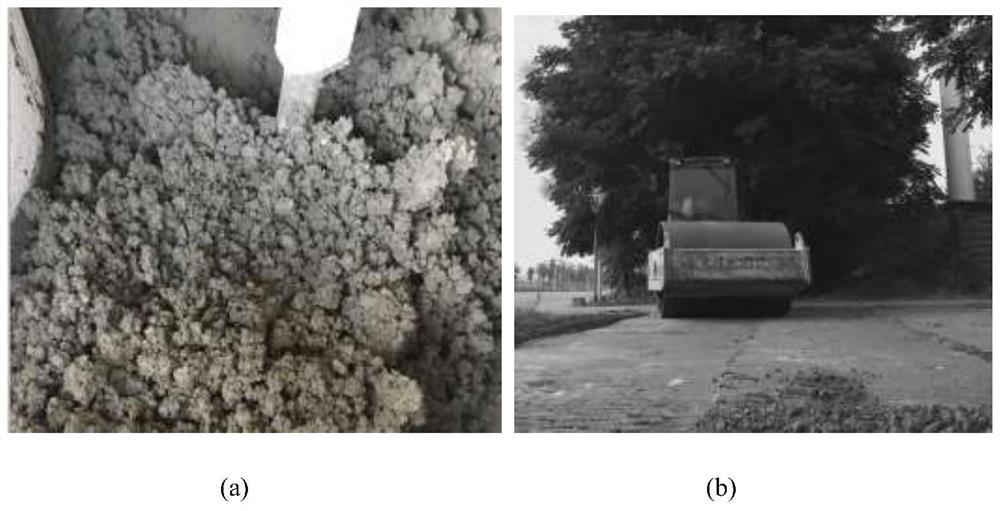

[0034] 3) The mixture obtained in step 2) is discharged out of the mixer, and placed at room temperature for 3 to 7 days, and then the river channel silt-based engineering soil can be obtained by rolling.

Embodiment 2

[0036] A kind of river course silt-based engineering soil, its preparation method comprises the steps:

[0037] 1) The raw materials are weighed, each component and its dosage conditions are: 700kg of river silt (4 days in the air, moisture content 28%), 230kg of construction waste slag, 50kg of fly ash, 20kg of cement, and a water-cement ratio of 0.15;

[0038] 2) Place the weighed river silt particles and construction waste slag in the mixing bin, and after stirring for 60 seconds, add fly ash in the stirring state, and stir for 30 seconds; then add cement in the stirring state, and stir for 30 seconds to obtain the mixture ;

[0039] 3) The mixture obtained in step 2) is discharged out of the mixer, and placed at room temperature for 3 to 7 days, and then the river channel silt-based engineering soil can be obtained by rolling.

Embodiment 3

[0041] A kind of river course silt-based engineering soil, its preparation method comprises the steps:

[0042] 1) The raw materials are weighed, the components and their dosage conditions are: 600kg of river mud (drying for 3 days, moisture content 35%), 300kg of construction waste slag, 50kg of fly ash, 50kg of cement, and a water-cement ratio of 0.15;

[0043]2) Place the weighed river silt particles and construction waste slag in the mixing bin, and after stirring for 60 seconds, add fly ash in the stirring state, and stir for 30 seconds; then add cement in the stirring state, and stir for 30 seconds to obtain the mixture ;

[0044] 3) The mixture obtained in step 2) is discharged out of the mixer, and placed at room temperature for 3 to 7 days, and then the river channel silt-based engineering soil can be obtained by rolling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com