High-solid amino resin for synthetic coating and preparation method thereof

An amino resin, high solid content technology, applied in the direction of coating, can solve the problems of complex preparation process, high baking temperature and low gloss of paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of preparation method of high-solid amino-containing resin for synthetic paint, method comprises the following steps:

[0023] ①Mix the alcoholic organic solvent and paraformaldehyde evenly, then raise the temperature to 70°C and keep it warm for 1 hour to obtain a transparent formaldehyde-polyol solution;

[0024] ②Then add melamine to the formaldehyde-polyol solution prepared in step ①, then raise the temperature to 90°C and keep it warm for 30min (carry out the methylolation reaction of melamine);

[0025] ③Then lower the temperature to 50°C, then add the modifier and catalyst, and keep the temperature at 50°C for 50 minutes to obtain the high-solid amino-containing resin for synthetic coatings.

Embodiment 2

[0027] A kind of preparation method of high-solid amino-containing resin for synthetic paint, method comprises the following steps:

[0028] ①Mix the alcoholic organic solvent and paraformaldehyde evenly, then raise the temperature to 80°C and keep it warm for 0.5h to prepare a transparent formaldehyde-polyol solution;

[0029] ②Then add melamine to the formaldehyde-polyol solution prepared in step ①, then raise the temperature to 100°C and keep it warm for 15min (carry out the methylolation reaction of melamine);

[0030] ③Then lower the temperature to 60°C, then add modifier and catalyst, and keep warm at 60°C for 30 minutes to obtain high-solid amino resin for synthetic coatings.

Embodiment 3

[0032] A kind of preparation method of high-solid amino-containing resin for synthetic paint, method comprises the following steps:

[0033] ①Mix the alcoholic organic solvent and paraformaldehyde evenly, then raise the temperature to 75°C and keep it warm for 0.8h to prepare a transparent formaldehyde-polyol solution;

[0034] ②Then add melamine to the formaldehyde-polyol solution prepared in step ①, then heat up to 95°C and keep it warm for 28min (carry out the methylolation reaction of melamine);

[0035] ③Then lower the temperature to 55°C, then add the modifier and catalyst, and keep the temperature at 55°C for 40 minutes to obtain the high-solid amino-containing resin for synthetic coatings.

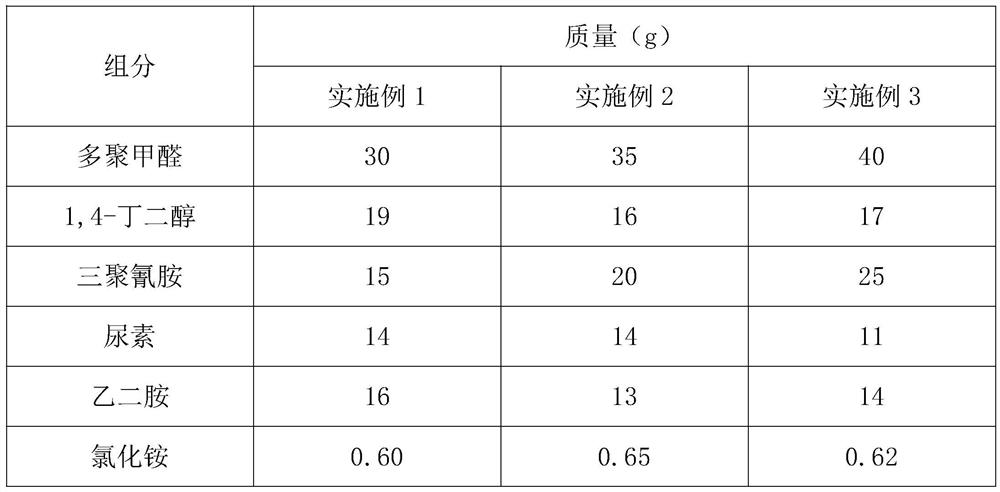

[0036] The mass percent of each component of table 1 embodiment 1-3

[0037]

[0038] Compared with the conventional methanol-etherified amino resin for the high-solid amino resin for synthetic coatings, the specific parameters of product quality are shown in Table 2.

[0039]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com