Isolation layer coating for heavy metal polluted basal plane as well as preparation method and application

An isolation layer and heavy metal technology, applied in the field of coatings, can solve the problems of secondary pollution of the surrounding environment and human harm, and achieve the effects of improving acid and alkali corrosion resistance, eliminating hazards and improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

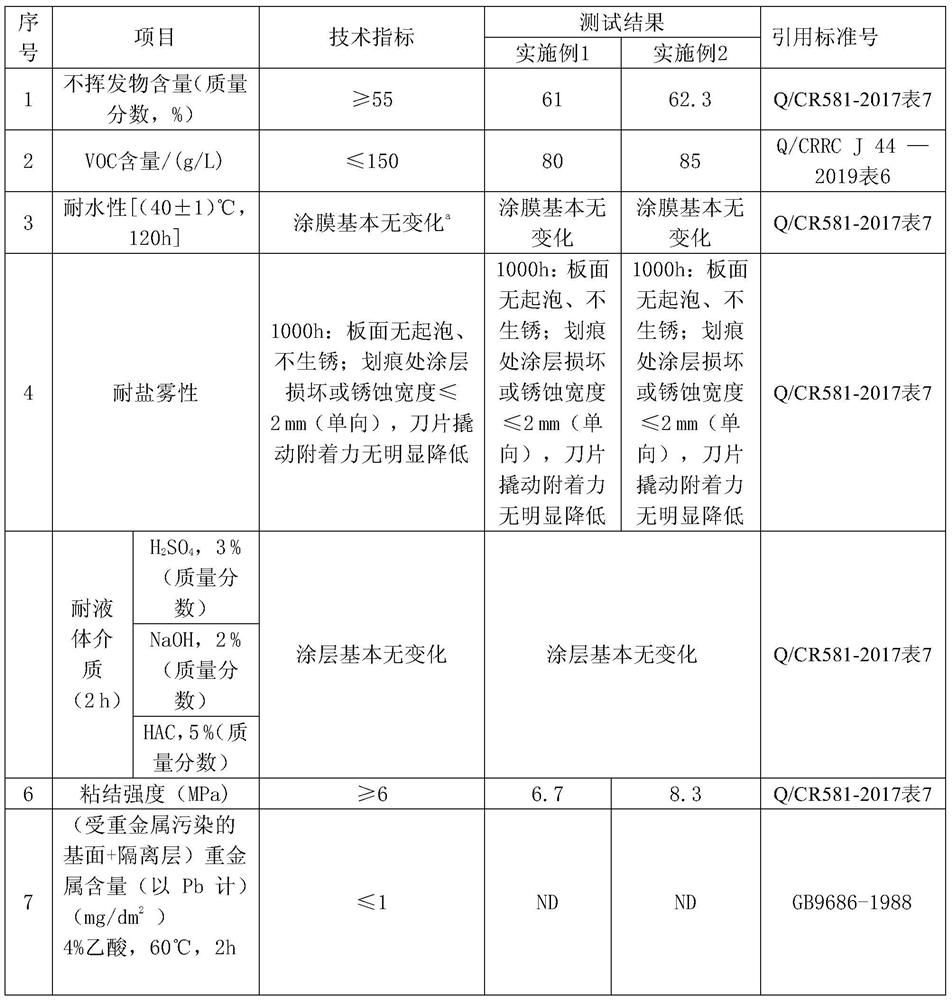

Examples

preparation example Construction

[0041]In a specific embodiment, the preparation method of above-mentioned coating comprises the following steps:

[0042] (1) Heat, stir and mix the medium molecular weight bisphenol A epoxy resin and emulsifier at a temperature of 70-85°C, and react the low molecular weight epoxy resin with the self-emulsifying epoxy curing agent, then emulsify, stir and disperse evenly, Then mix the above resins with different molecular weights, add water to emulsify, then add surfactants, complexing agents, dispersants, defoamers, thickeners, etc. to mix and disperse evenly at a temperature of 30-60°C to obtain component A ;

[0043] (2) Mix the water-based non-ionic epoxy curing agent, organic solvent and water evenly to obtain component B;

[0044] (3) Mix components A and B uniformly in proportion to obtain a cured isolation layer coating for the base surface polluted by heavy metals.

[0045] The cured isolation layer coating of the invention can be applied to the surface anticorrosio...

Embodiment 1

[0047] The water-based barrier coating of this embodiment is composed of two components, A and B, and the mass ratio of A and B components is 5:1; wherein, A component includes the following ingredients by weight: 40.5 parts of bisphenol A Type medium molecular weight E20 epoxy resin, 31.5 parts of low molecular weight epoxy resin E51, 1 part of surfactant fatty alcohol polyoxyethylene ether, 3 parts of complexing agent and 15.5 parts of deionized water, 0.5 part of thickener; component B It includes the following components by weight: 90 parts of non-ionic modified amine curing agent EX100, 8 parts of water and 2 parts of propylene glycol methyl ether.

[0048] The preparation method of the water-based barrier coating of the present embodiment may further comprise the steps:

[0049] (1) 405kg of bisphenol A type medium molecular weight E20 epoxy resin emulsified by emulsifier, 315KG of low molecular weight epoxy resin E51, 10kg fatty alcohol polyoxyethylene ether, 30kg emuls...

Embodiment 2

[0054] The water-based isolation layer coating of this embodiment is composed of two components, A and B, and the mass ratio of component A and component B is 5:1.5; wherein, component A includes the following components by mass: 49.5 parts of bisphenol A Type epoxy resin E20, 22.5 parts of bisphenol A type epoxy resin E51, 1 part of surfactant fatty alcohol polyoxyethylene ether, 1 part of complexing agent, 15.5 parts of deionized water, 0.5 part of thickener; component B It includes the following components by weight: 70 parts of non-ionic modified amine curing agent EX100, 20 parts of water and 10 parts of propylene glycol methyl ether.

[0055] The preparation method of the water-based barrier coating of the present embodiment may further comprise the steps:

[0056] (1) 495kg of bisphenol A type epoxy resin E51, 10kg fatty alcohol polyoxyethylene ether, 10kg of bisphenol A type epoxy resin emulsified after the reaction of self-emulsifying epoxy curing agent after emulsify...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com