Method for preparing super-hydrophobic zinc-aluminum hydrotalcite coating on surface of aluminum alloy

A technology of aluminum alloy surface and hydrotalcite, applied in metal material coating process, coating, etc., can solve the problems of unfavorable popularization and application, high cost, complicated process flow, etc., and achieve easy popularization and application, good protection and wide source Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Grind the 6061 aluminum alloy sample on 240#, 400#, 600#, 1000#, 1500# SiC sandpaper in order to remove the oxide film on the surface of the sample, and then put the sample in absolute ethanol and Ultrasonic cleaning in deionized water for 10 minutes to remove impurities and oil stains on the surface of the sample, take it out and dry it with cold wind for later use;

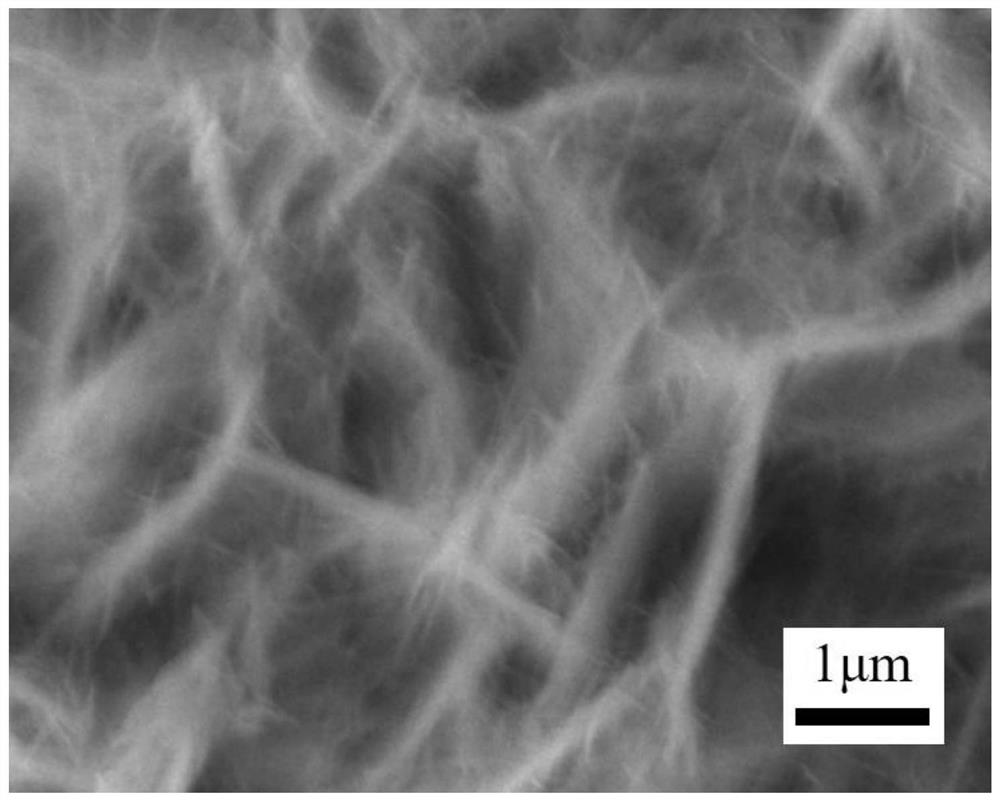

[0023] (2) Preparation containing 0.015mol / L ZnSO 4 ·7H 2 A mixed solution of O and 0.1mol / L urea, fully stirred to make the solution evenly mixed; place the aluminum alloy sample treated in step (1) and the above mixed solution in a hydrothermal reaction kettle, and place it in a drying oven at 120°C React for 8 hours; after the reaction, take out the sample, wash it repeatedly with deionized water, dry it with cold air, and get a zinc-aluminum hydrotalcite coating on the surface of the aluminum alloy;

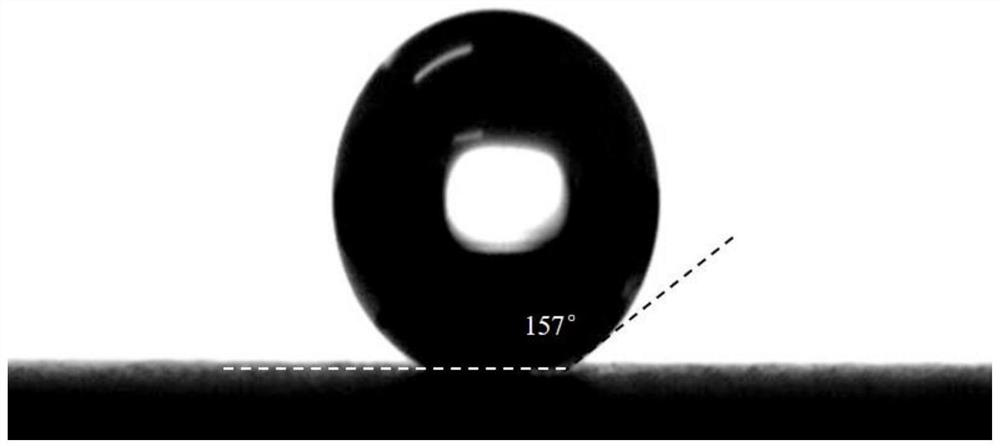

[0024] (3) Dissolve 0.01mol stearic acid in 100mL absolute ethanol, fully stir to make the solu...

Embodiment 2

[0026] (1) Grind the 6061 aluminum alloy sample on 240#, 400#, 600#, 1000#, 1500# SiC sandpaper in order to remove the oxide film on the surface of the sample, and then put the sample in absolute ethanol and Ultrasonic cleaning in deionized water for 10 minutes to remove impurities and oil stains on the surface of the sample, take it out and dry it with cold wind for later use;

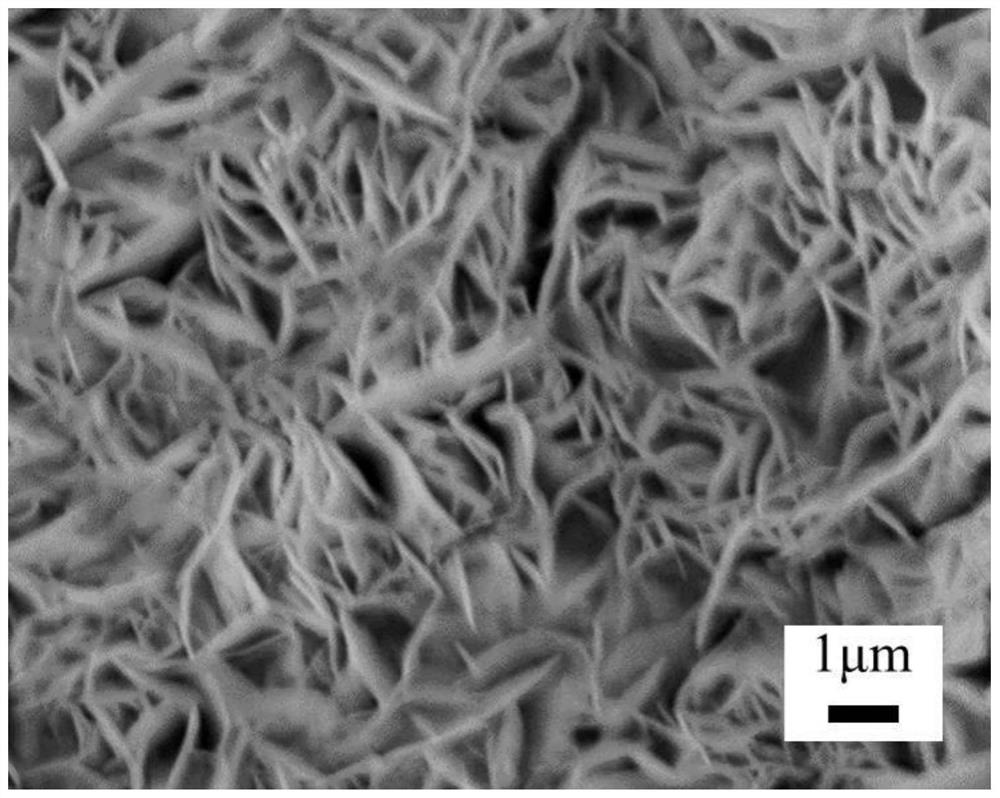

[0027] (2) Preparation containing 0.015mol / L ZnSO 4 ·7H 2 A mixed solution of O and 0.1mol / L urea, fully stirred to make the solution evenly mixed; place the aluminum alloy sample treated in step (1) and the above mixed solution in a hydrothermal reaction kettle, and place it in a drying oven at 100°C React for 8 hours; after the reaction, take out the sample, wash it repeatedly with deionized water, dry it with cold air, and get a zinc-aluminum hydrotalcite coating on the surface of the aluminum alloy;

[0028] (3) Dissolve 0.01mol stearic acid in 100mL absolute ethanol, fully stir to make the solu...

Embodiment 3

[0030] (1) Grind the 6061 aluminum alloy sample on 240#, 400#, 600#, 1000#, 1500# SiC sandpaper in order to remove the oxide film on the surface of the sample, and then put the sample in absolute ethanol and Ultrasonic cleaning in deionized water for 10 minutes to remove impurities and oil stains on the surface of the sample, take it out and dry it with cold wind for later use;

[0031] (2) Preparation containing 0.005mol / L ZnSO 4 ·7H 2 Mixed solution of O and 0.05mol / L urea, fully stirred to make the solution evenly mixed; place the aluminum alloy sample treated in step (1) and the above mixed solution in a hydrothermal reaction kettle, and place it in a drying oven at 100°C React for 6 hours; after the reaction, take out the sample, wash it repeatedly with deionized water, dry it with cold air, and get a zinc-aluminum hydrotalcite coating on the surface of the aluminum alloy;

[0032](3) Dissolve 0.005mol stearic acid in 100mL absolute ethanol, fully stir to make the solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com