A kind of circulating drying device for lithium battery raw material processing

A drying device and lithium battery technology, which is applied to heating devices, drying, dryers and other directions, can solve the problems of affecting the drying effect of lithium battery raw materials, the difficulty of rapid evaporation of water droplets, and the inability to collect and utilize them. Realize the effect of increasing drying time, feeding amount and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

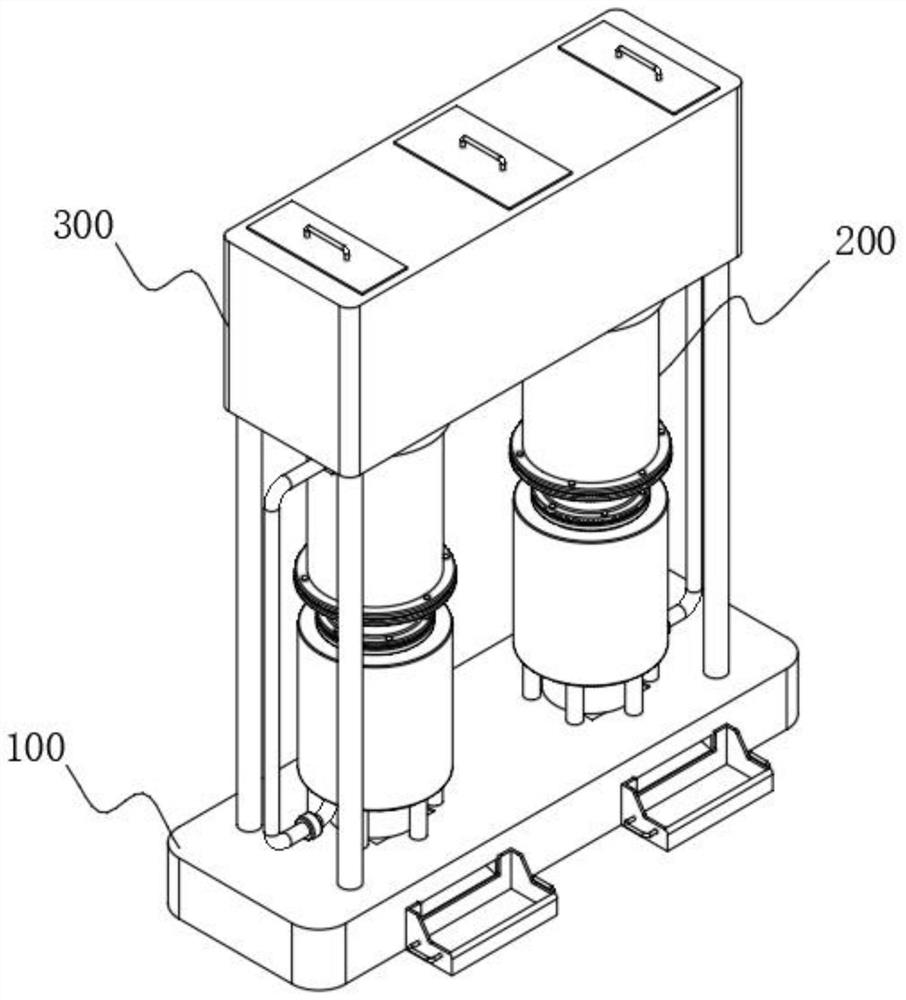

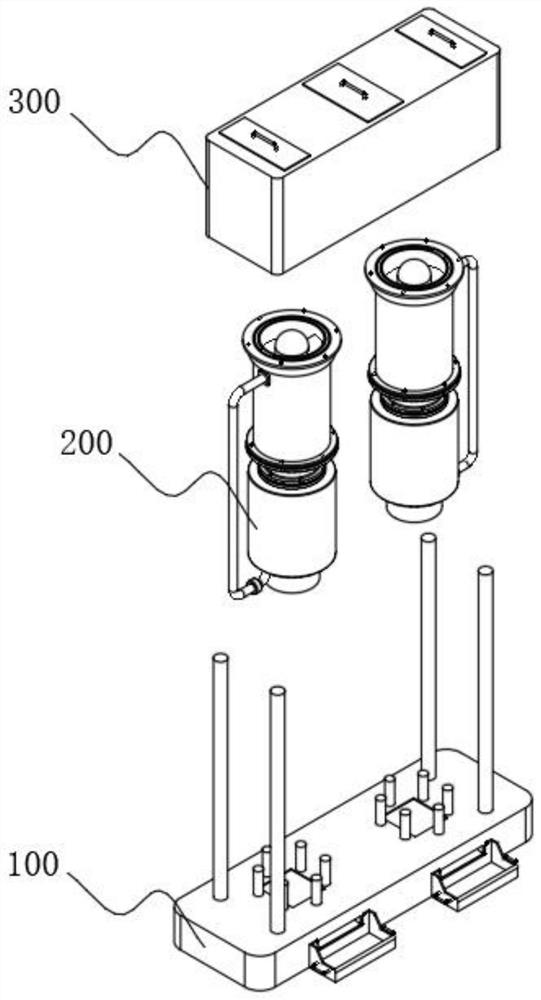

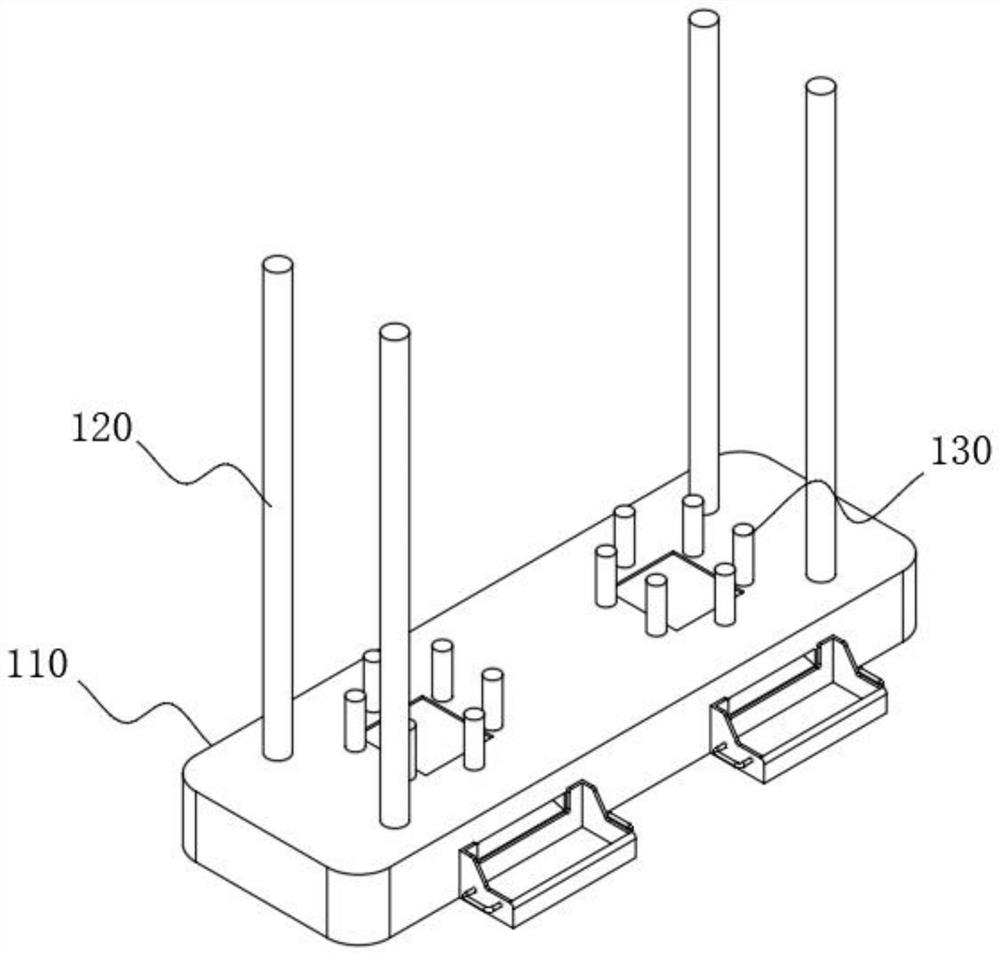

[0063] see Figure 1-Figure 13 As shown in the figure, the purpose of this embodiment is to provide a cyclic drying device for lithium battery raw material processing, including a support mechanism 100, two cyclic drying mechanisms 200 arranged on the top of the support mechanism 100, and two circulating drying mechanisms 200 arranged on the cyclic drying mechanism 200. The feeding mechanism 300 at the top, the support mechanism 100 includes a base 110, the base 110 is arranged at the bottom of the circulating drying mechanism 200, the circulating drying mechanism 200 includes a heating drying device 210, and the heating drying device 210 includes a heating barrel 211, and the heating barrel The interior of 211 is provided with a heating cavity, and the heating cavity is provided with a heating plate 212. The right side of the heating plate 212 is not closed, so as to provide space for the insertion of the top plug-in tube 232. The electric heating device for cavity heating, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com