Catalyst for inhibiting mercaptan low-temperature sulfur-tolerant shift as well as preparation method and application thereof

A technology of sulfur-resistant shift and catalyst, applied in chemical instruments and methods, chemical elements of heterogeneous catalysts, catalysts for physical/chemical processes, etc., can solve the problem of high mercaptan content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

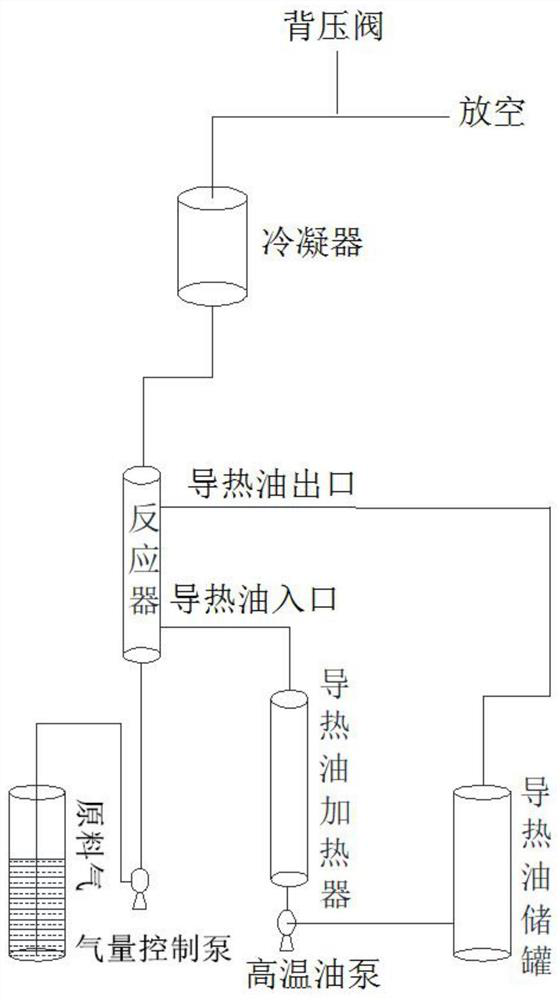

Image

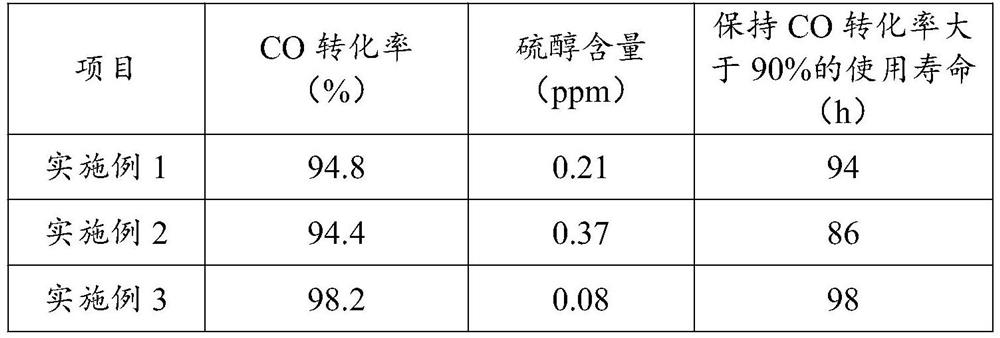

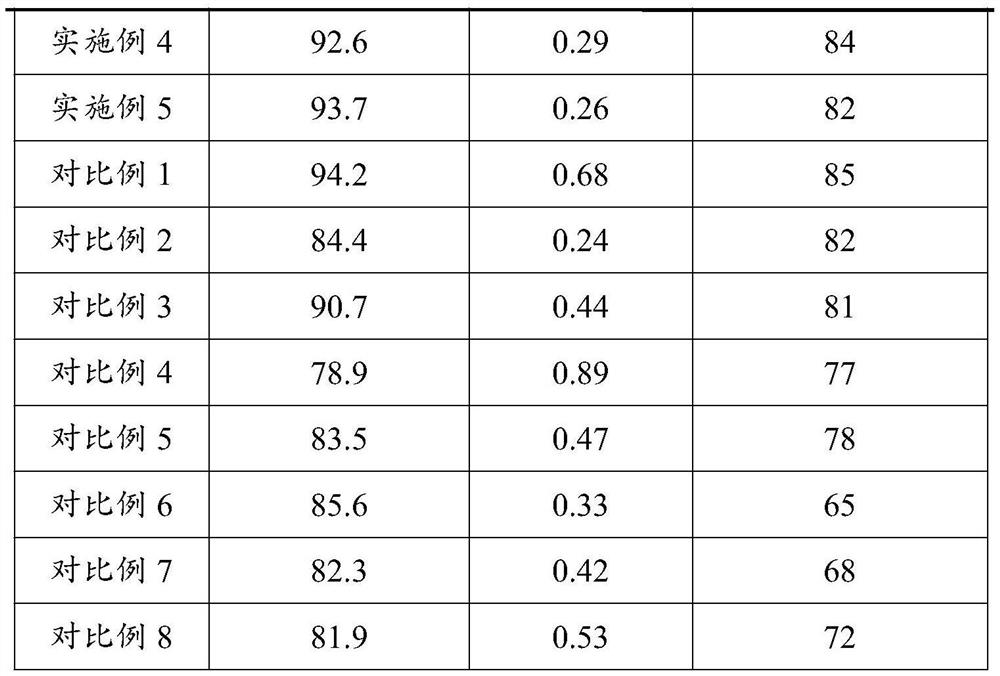

Examples

preparation example Construction

[0033] The present invention provides the preparation method of the mercaptan-suppressing low-temperature sulfur-resistant shift catalyst described in the technical solution, comprising the following steps:

[0034] Mixing gamma-alumina, soluble zirconium salt, binder and water for the first time to obtain a mixed slurry;

[0035] Carrying out the first roasting of the mixed slurry to obtain the first precursor;

[0036] The cobalt-containing compound, the molybdenum-containing compound, and the potassium-containing compound are mixed with water for a second time to obtain an active metal impregnating solution;

[0037] Immersing the first precursor in an active metal impregnation solution to obtain a second precursor;

[0038] The second precursor is subjected to second calcination to obtain the low-temperature sulfur-tolerant shift catalyst for suppressing mercaptans.

[0039] In the present invention, unless otherwise specified, all raw materials used are commercially ava...

Embodiment 1

[0067] Weigh 500g of γ-alumina (particle size 48~75μm, pore volume 0.2~0.45cm 3 / g, specific surface area 200~350m 2 / g), 20g of simple carbon (particle size 48-75μm) and 30g of cement are dry mixed, and the dry mixing time is 20min, so that they are fully mixed to obtain a dry mix;

[0068] Add 20g of zirconium chloride into 150g of pure water for dissolution to obtain a zirconium chloride solution, then add the zirconium chloride solution to the dry mix, add in batches, stir during the addition until it becomes muddy, install The abrasive tool is extruded through an extruder to obtain a Φ4mm cylindrical body, and the body is dried at 120°C for 2 hours, and then the first calcination is carried out at 450°C for 4 hours to obtain the first precursor;

[0069] Basic cobalt carbonate, ammonium tetramolybdate, potassium carbonate and water are configured into an active metal compound solution, wherein the mass content of cobalt element is 2.5%, the mass content of molybdenum ele...

Embodiment 2

[0073] Weigh 500g of γ-alumina (particle size 48~75μm, pore volume 0.2~0.45cm 3 / g, specific surface area 200~350m 2 / g), 20g attapulgite (particle size 48~75μm) and 30g cement carry out dry mixing, and the dry mixing time is 20min, make it fully mix, obtain dry mix;

[0074] Add 15g of zirconium chloride into 150g of pure water for dissolution to obtain a zirconium chloride solution, then add the zirconium chloride solution to the dry mix, add in batches, stir during the addition until it becomes muddy, install The abrasive tool is extruded through an extruder to obtain a Φ4mm cylindrical body, and the body is dried at 120°C for 2 hours, and then the first calcination is carried out at 450°C for 4 hours to obtain the first precursor;

[0075] Basic cobalt carbonate, ammonium tetramolybdate, potassium carbonate and water are configured into an active metal compound solution, wherein the mass content of cobalt element is 2.5%, the mass content of molybdenum element is 7%, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com