Four-way shuttle type transfer robot for warehouse logistics

A technology for handling robots and warehousing logistics, which is applied in the directions of transportation and packaging, lifting devices, storage devices, etc. It can solve the problems of unfavorable storage space, polluted goods, high cost, etc., and achieve the goal of increasing the storage capacity of robots, saving overall space, and reducing construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

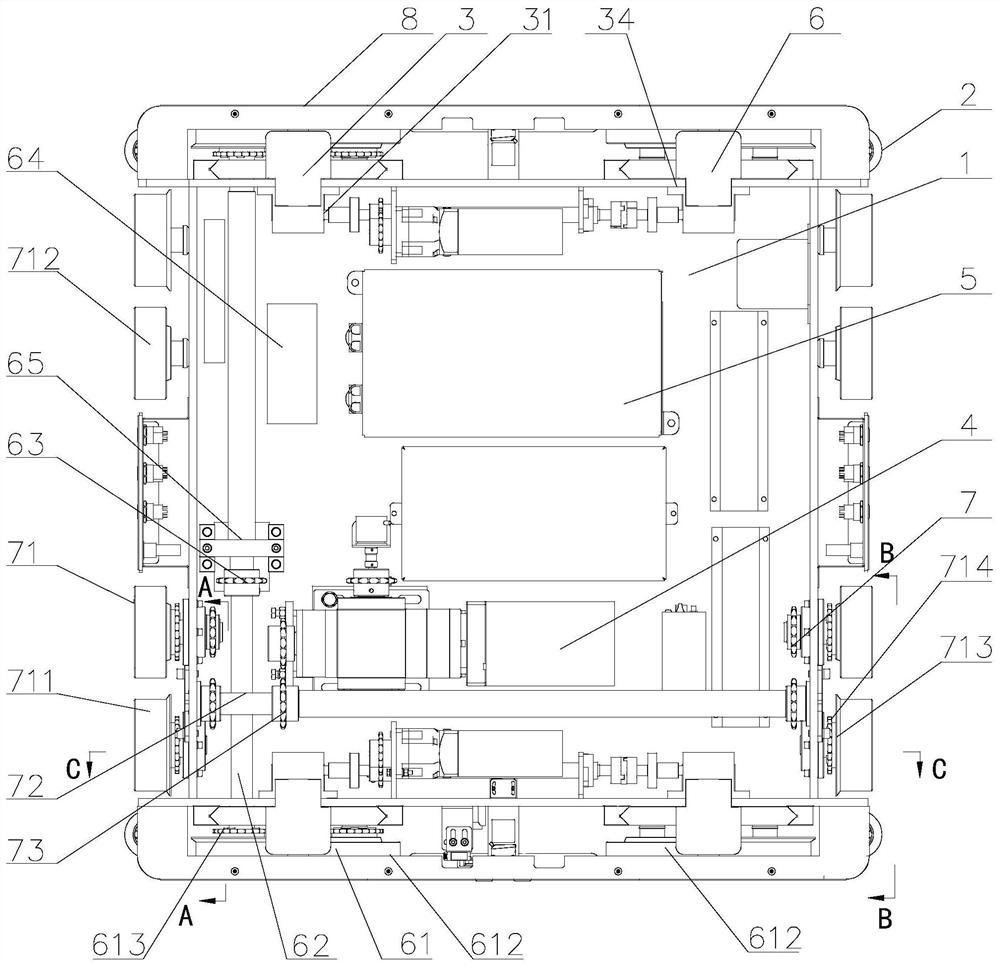

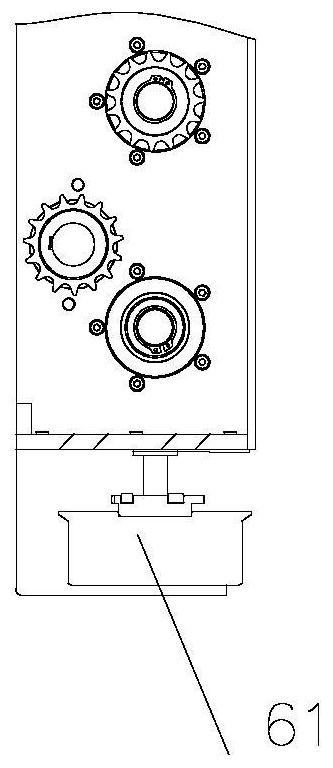

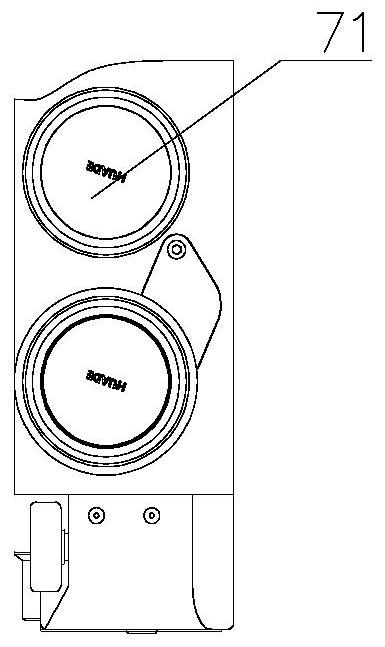

[0025] This embodiment provides a four-way shuttle handling robot for warehousing logistics, the structure is as follows Figures 1 to 6 As shown, it includes a frame 1 and a screw lifting mechanism 3 arranged in the frame, a walking drive mechanism 4 and a power control unit 5, the screw lifting mechanism 3 and the walking driving mechanism 4 are controlled by the power control unit 5, and the surroundings of the frame The main channel wheel assembly 6 and the auxiliary channel wheel assembly 7 are installed, the outside of the main channel wheel assembly and the auxiliary channel wheel assembly is provided with a road wheel protective cover 8, and the four corners of the frame are provided with guide wheels 2; the main channel wheel assembly 6 includes main Channel wheel 61, main channel transmission shaft 62 and first sprocket pair 63, main channel wheel 61 is symmetrically arranged on both sides of the frame in the main channel running direction, and the two ends of main ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com