Glass magnesium board with good sound insulation effect and preparation method thereof

A glass-magnesium board and magnesite technology is applied in the field of glass-magnesium board and its preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039]The preparation method of the glass magnesium board includes the following steps:

[0040]Step S1: Put the prepared high-activity magnesium oxide into a ball mill for 30 minutes and grind it through a 180-mesh sieve for later use. Add pure water to the magnesium chloride to fully dissolve it into a solution and let it stand for 24 hours and mix with the high-activity magnesium oxide, then pour it into a mixer and stir evenly After adding plant fiber, filler, magnesite water resistant powder, and modified polyurethane, continue to stir to form a flour paste, the stirring speed is 400-500r / min, and the time is 20min;

[0041]Step S2: Pour the configured flour paste into the template of the forming machine. The forming machine is provided with two layers of low-alkali glass fiber cloth. The flour paste is placed between the upper and lower layers of low-alkali glass fiber cloth and is formed by roll forming. The molding temperature is controlled at 30℃, and the molding time is 25-28 ho...

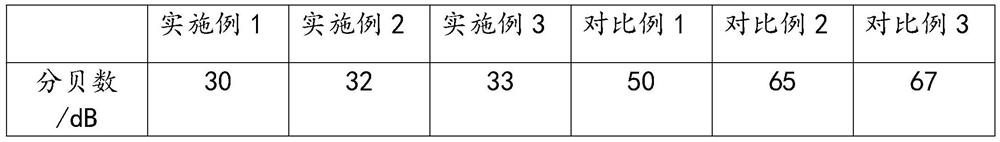

Embodiment 1

[0044]A glass magnesium board with good sound insulation effect includes the following raw materials by weight: 60 parts of highly active magnesium oxide, 30 parts of magnesium chloride, 6 parts of alkali-resistant glass fiber cloth, 5 parts of plant fiber, 5 parts of magnesite water-resistant powder, and 20 parts of filler , 20 parts of modified polyurethane;

[0045]The preparation method of the glass magnesium board includes the following steps:

[0046]Step S1: Put the prepared high-activity magnesium oxide into a ball mill for 30 minutes and grind it through a 180-mesh sieve for later use. Add pure water to the magnesium chloride to fully dissolve it into a solution and let it stand for 24 hours and mix with the high-activity magnesium oxide, then pour it into a mixer and stir evenly After adding plant fiber, filler, magnesite water resistant powder, and modified polyurethane, continue to stir to form a flour paste, the stirring speed is 400r / min, and the time is 20min;

[0047]Step S2:...

Embodiment 2

[0050]A glass magnesium board with good sound insulation includes the following raw materials by weight: 65 parts of highly active magnesium oxide, 35 parts of magnesium chloride, 7 parts of alkali-resistant glass fiber cloth, 8 parts of plant fiber, 6 parts of magnesite water-resistant powder, and 25 parts of filler , 25 parts of modified polyurethane;

[0051]The preparation method of the glass magnesium board includes the following steps:

[0052]Step S2: Put the prepared high-activity magnesium oxide into a ball mill for 30 minutes and grind it through a 180-mesh sieve for later use. Add pure water to the magnesium chloride and fully dissolve it into a solution. After standing for 24 hours, mix with the high-activity magnesium oxide, then pour it into a mixer and stir evenly After adding plant fiber, filler, magnesite water resistant powder, and modified polyurethane, continue to stir to form a flour paste, the stirring speed is 450r / min, and the time is 20min;

[0053]Step S3: Pour the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com