Polyurea resin as well as preparation method and application thereof

A polyurea resin and resin technology, applied in the field of polyurea resin and its preparation, can solve problems such as easy bubbling, and achieve the effects of low cost, good water resistance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

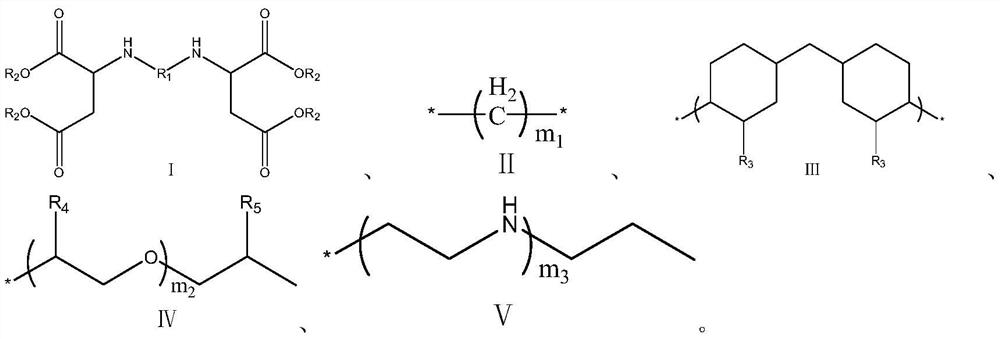

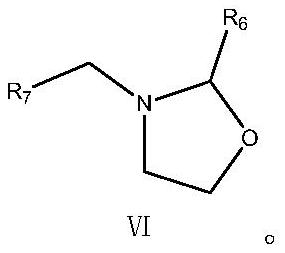

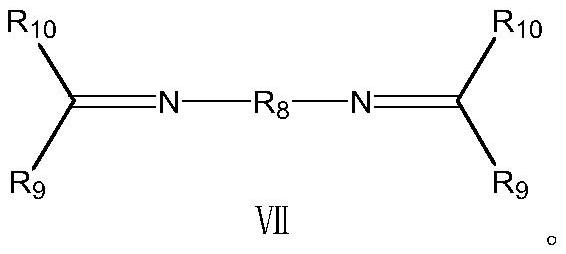

Method used

Image

Examples

preparation example Construction

[0055] The second aspect of the present invention provides the preparation method of the polyurea resin, comprising the following steps: under the dry condition protected by an inert gas, uniformly mixing the raw materials to obtain the obtained polyurea resin.

[0056] The third aspect of the present invention provides the application of the polyurea resin in the preparation of polyurea coatings.

Embodiment 1

[0061] Example 1 provides a polyurea resin, the preparation method of which is as follows: under the condition of nitrogen protection in a dry flask, add polyaspartic acid ester resin E1, oxazolidine compound F1 and stir and mix evenly to obtain; The weight ratio of the aspartate resin E1 to the oxazolidine compound F1 is 7:3.

[0062]

Embodiment 2

[0064] Example 2 provides a polyurea resin, the preparation method of which is as follows: in the case of nitrogen protection in a dry flask, add polyaspartic acid ester resin E1 and oxazolidine compound F2, stir and mix evenly, to obtain final product; The mass ratio of the polyaspartic ester resin E1 to the oxazolidine compound F2 is 8:2.

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com