Drilling device with dust removal function

A drilling and equipment technology, applied in the field of drilling equipment with dust removal function, can solve the problems of large dust and environmental pollution, and achieve the effect of avoiding pollution and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The invention provides a drilling equipment with dust removal function.

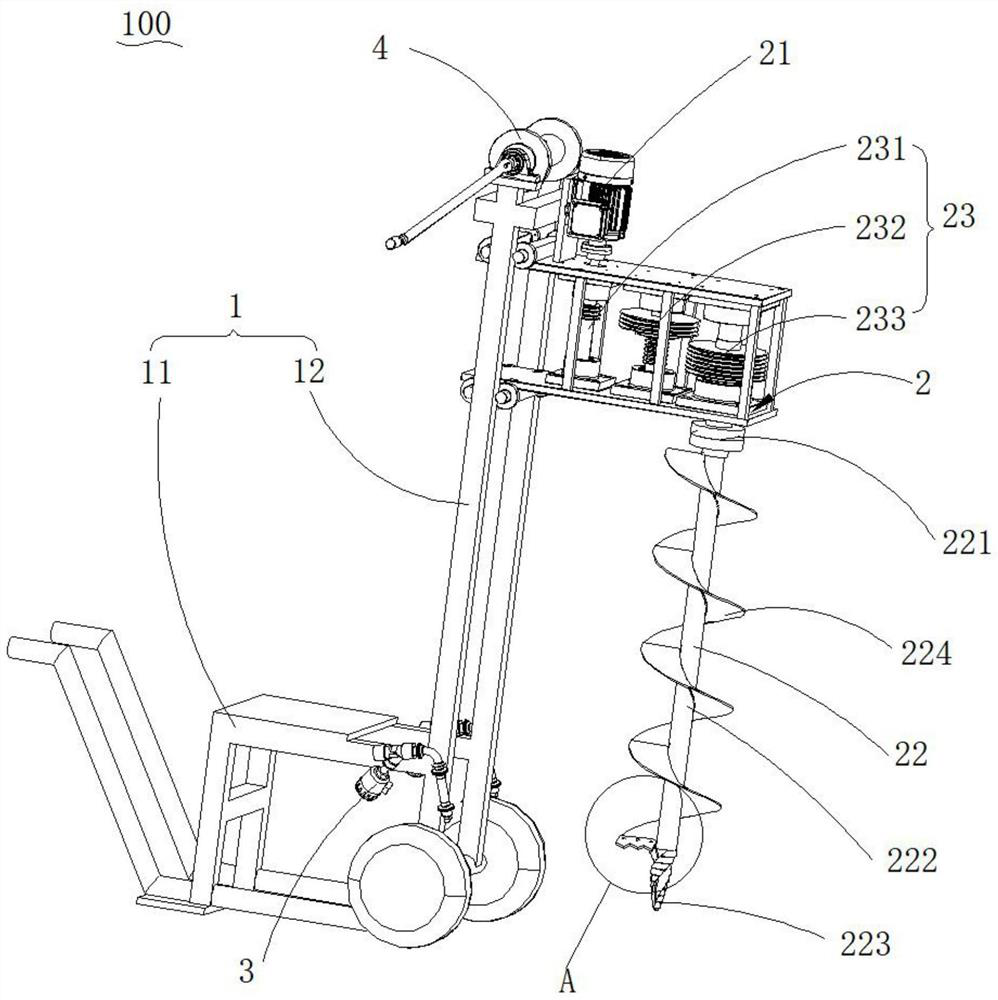

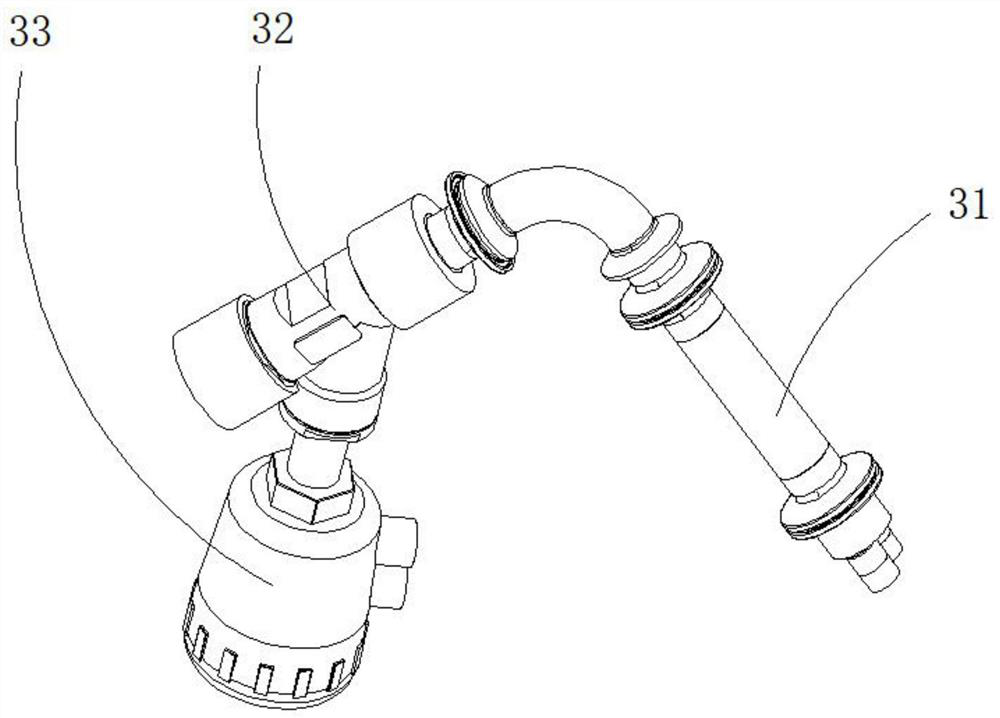

[0028] Such as Figure 1 to Figure 3 As shown, a drilling equipment 100 with dust removal function in this embodiment includes an installation platform 1, a drilling device 2 and a dust removal device 3, wherein the drilling device 2 is installed on the installation platform 1, and the drilling device 2 includes a drill pipe 22 and a drive The motor 21, the drive motor 21 drives the drill pipe 22 to rotate; the dust removal device 3 includes a spray head 31 and a connecting pipe head 32, the connecting pipe head 32 communicates with the external water pipe, the connecting pipe head 32 is installed on the installation platform 1, and the spray head 31 Installed on the connecting pipe head 32 , the shower head 31 is set right against the drill pipe 22 .

[0029] Specifically, a kind of drilling equipment 100 with dust removal function in this embodiment is provided with a sprinkler 31 on the instal...

Embodiment 2

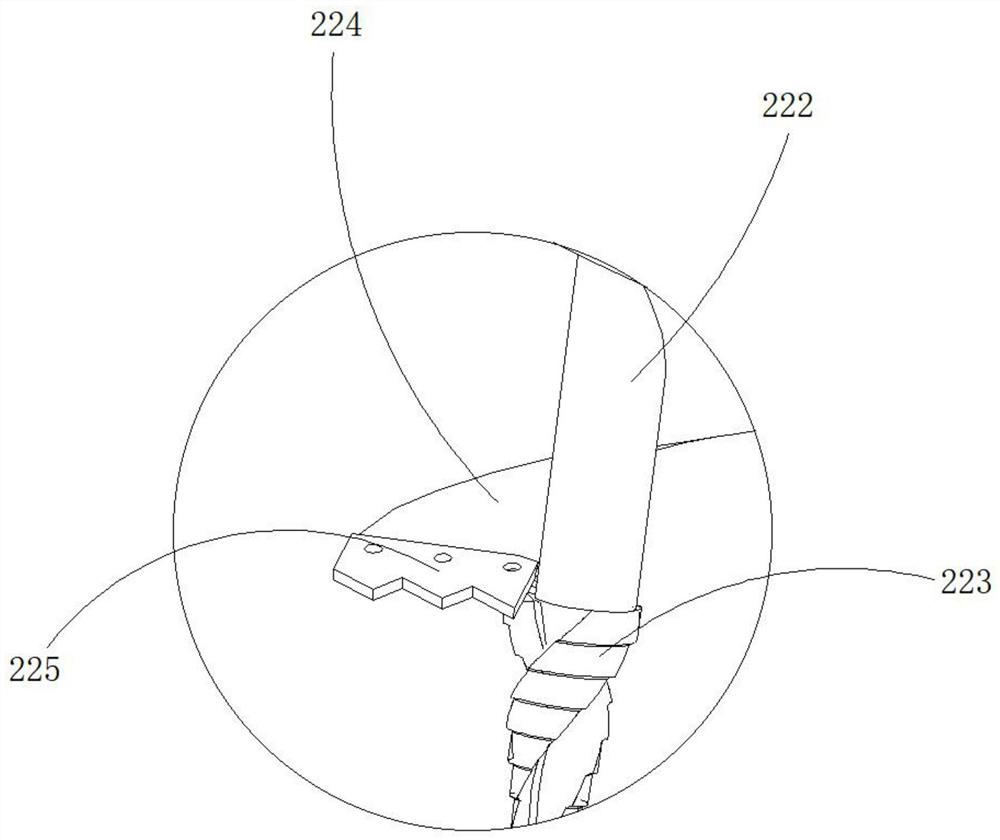

[0037] On the basis of the above-mentioned embodiments, the drilling equipment with dust removal function provided by the present application also includes a secondary spray system (not shown in the drawings), which includes a spray box, spray A shower channel, wherein the shower channel is a capillary channel that runs through the inside of the drill pipe 22, the diameter of the capillary channel can be 1-5mm, and one end of the spray channel extends to the end of the drill pipe 22 near the transmission assembly 23. Water inlet, the water inlet communicates with the water inlet pipe to the spray box through a seal, the other end of the spray channel extends to the end of the drill pipe 22 near the drilling end 223 to be provided with a water outlet, and the water outlet is sealed with a tapered A shower head, and the direction of the conical shower head is the same as that of the helical blade 224 at the bottom. In the embodiment of the present application, the same content a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com