Preparation method of dimethyl succinyl succinate

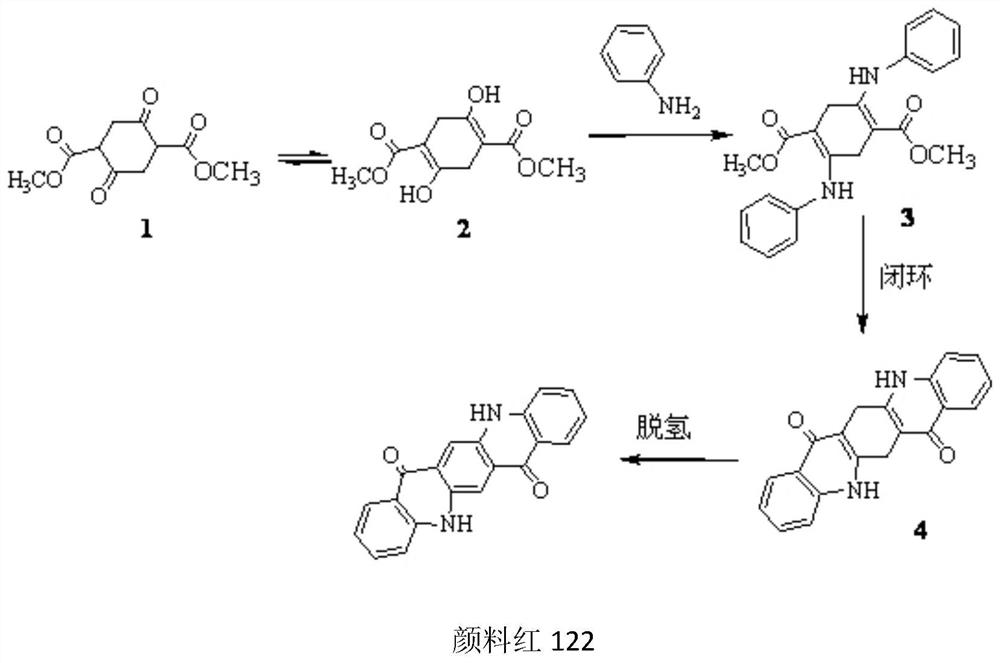

A technology of dimethyl succinyl succinate and dimethyl succinate, applied in the field of preparation of dimethyl succinyl succinate, can solve the problems of unsatisfactory improvement of production efficiency and quality, etc. Achieve the effects of improving synthesis efficiency, simple preparation process, and high purity of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

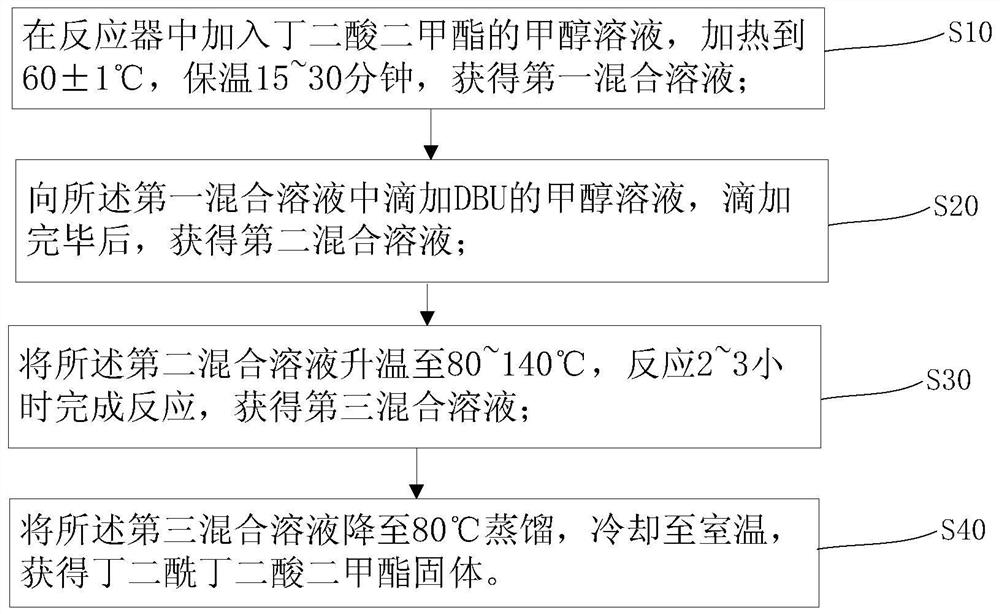

[0021] The present embodiment provides a kind of preparation method of dimethyl succinyl succinate, such as Figure 2~3 As shown, it includes the following steps: S10 Adding methanol solution of dimethyl succinate into the reactor, heating to 60±1° C., and keeping the temperature for 15-30 minutes to obtain the first mixed solution. S20 Add dropwise a methanol solution of 1,8-diazacyclo[5,4,0]undecene-7 (DBU) into the first mixed solution, and obtain a second mixed solution after the dropwise addition is completed. S30 raising the temperature of the second mixed solution to 80-140° C., and reacting for 2-3 hours to complete the reaction to obtain a third mixed solution. and S40, reducing the third mixed solution to 80° C. for distillation, and cooling to room temperature to obtain dimethyl succinyl succinate as a solid.

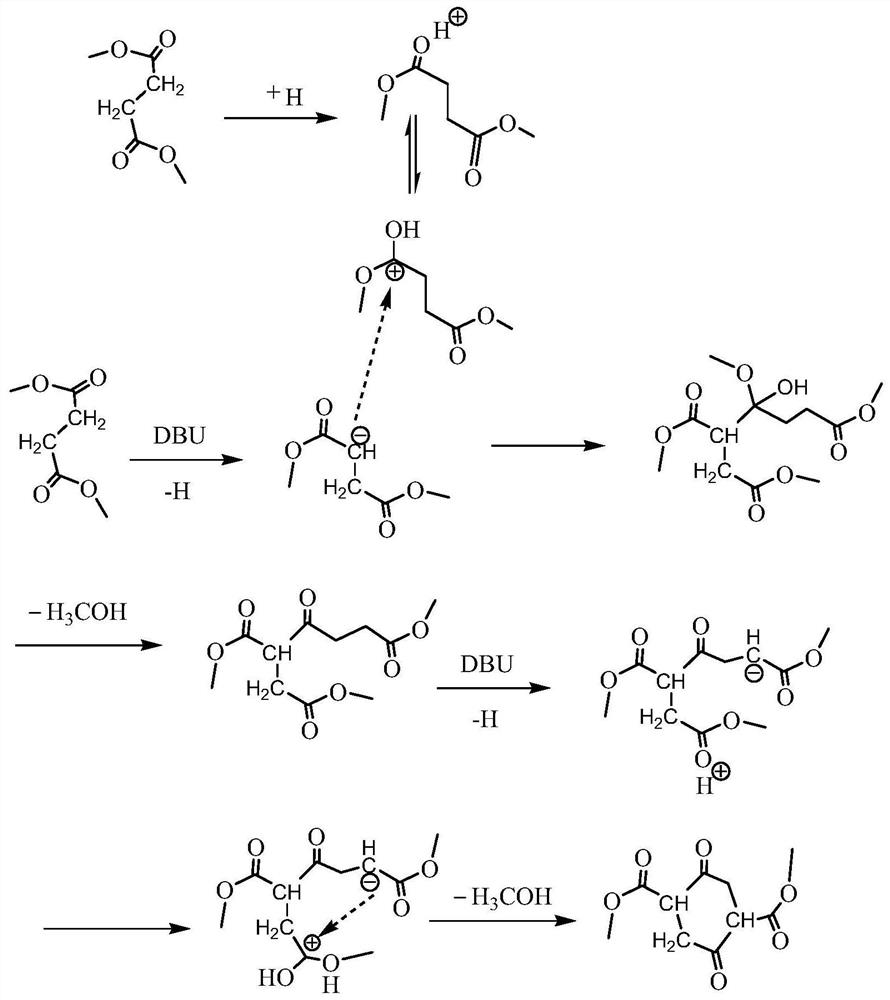

[0022] The Claisen condensation reaction refers to the reaction in which an ester containing α-hydrogen is condensed under the action of a basic condensing ...

Embodiment 1

[0026] S10 Add 29.23g of dimethyl succinate (manufactured by Sinopharm) and 100ml of anhydrous methanol solution to a 500ml four-neck flask respectively, heat up to 60°C while stirring, and keep for 15min to obtain the first mixed solution.

[0027] S20 Add dropwise 50 ml of a methanol solution of DBU with a mass fraction of 0.58% to the first mixed solution, and obtain a second mixed solution after the dropwise addition is completed.

[0028] S30 raising the temperature of the second mixed solution to 80° C., and reacting for 2 hours to complete the reaction to obtain a third mixed solution.

[0029] S40 Distill the third mixed solution at 80° C., collect the distilled mixed solution of DBU and methanol, and cool the remaining solution to room temperature to obtain 21.7 g of dimethyl succinyl succinate as a solid, with a yield of 95%.

Embodiment 2

[0031] S10 Add 70 kg of dimethyl succinate (manufactured by Changzhou Xiaqing Technology Co., Ltd., purity> 98%) and 100 kg of anhydrous methanol solution into the reaction kettle respectively, stir while raising the temperature to 60° C., and keep it for 25 minutes to obtain the first mixture.

[0032] S20 Add dropwise 10 kg of a methanol solution of DBU with a mass fraction of 7% to the first mixed solution, and obtain a second mixed solution after the dropwise addition is completed.

[0033] S30 pressurizes and raises the temperature of the second mixed solution to 140° C., and reacts for 3 hours to complete the reaction to obtain a third mixed solution.

[0034] S40 Distill the third mixed solution at 80° C., collect the distilled mixed solution of DBU and methanol, and cool the remaining solution to room temperature to obtain 51.8 kg of dimethyl succinyl succinate as a solid, with a yield of 94.96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com