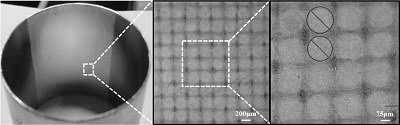

Device for continuous mask electrolytic machining of metal microstructure

A metal microstructure and mask technology, which is applied in electrochemical processing equipment, electrolytic process, electrolytic components, etc., can solve the problems of low adaptability, low precision and surface quality of metal micro-nano structure, low process stability, etc. , to achieve a wide range of applications, consistent shape and size, favorable surface quality, and high process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

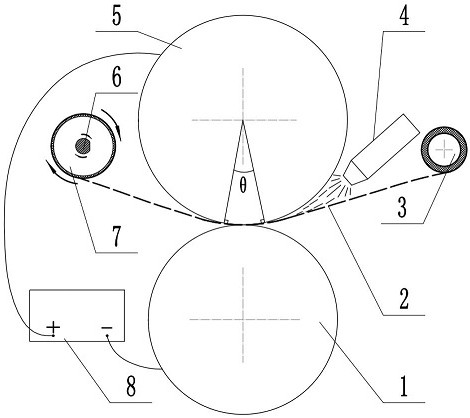

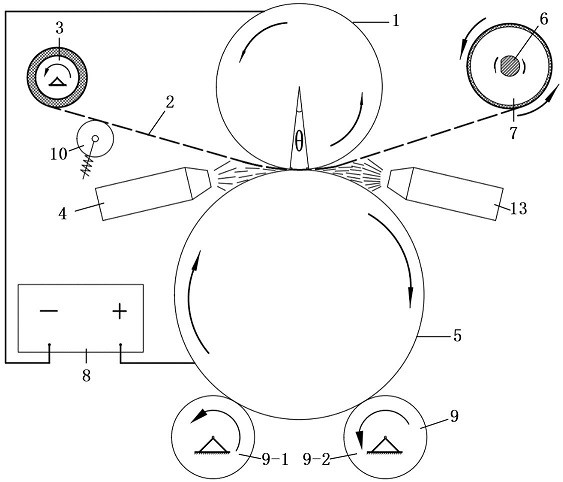

[0033] Combine below Figure 2 to Figure 9 The implementation of the present invention is further described in detail: a device for continuous mask electrolytic machining of metal microstructures, comprising a liquid spray nozzle 4, an electrolysis power supply 8, a workpiece anode 5, a tool cathode 1, and an air nozzle 13, and is characterized in that: it It also includes a mask belt 2, a storage pulley 3, a take-up pulley 7, a driving source 6, an idler roller 9 and a tension pulley 10; the storage pulley 3, the tension pulley 10 and the take-up pulley 7 are all cylindrical body shape; one end of the mask tape 2 is wound on the take-up pulley 7, and the other end is wound on the storage pulley 3; the take-up pulley 7 is connected with the drive source 6, and is driven by the drive source 6 The bottom can be rotated clockwise; the storage pulley 3 and the tension pulley 10 can rotate around their own rotation center axis; the tool cathode 1 is in the shape of a cylinder; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com