Production and preparation method of graphene powder

A graphene powder and graphene technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of poor physical properties of graphene powder, complex methods, complex structure, etc., and achieve stable and durable anti-aging function , high preparation efficiency and dense coating surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

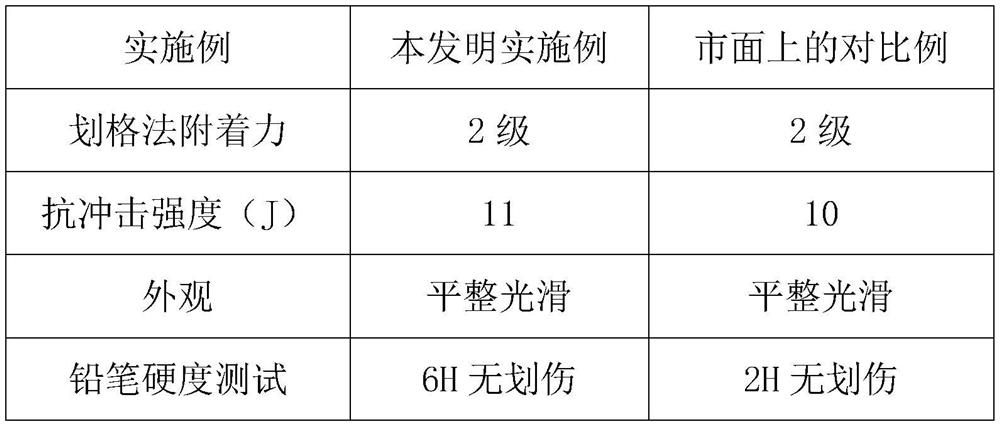

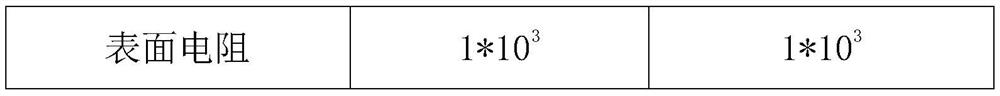

Examples

Embodiment Construction

[0021] The technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them.

[0022] A production and preparation method of graphene powder, comprising the following preparation steps:

[0023] S1: Prepare raw materials: graphite oxide; disperse the graphite oxide, then pickle and wash with water, and finally perform ultrasonic vibration treatment to form a graphene oxide nano-layer mixture;

[0024] S2: Add reducing agent and catalyst to the mixed liquid, heat, and then perform reflux treatment;

[0025] S3: filtering the refluxed mixed solution, and then washing to form a filter cake;

[0026] S4: drying the filter cake in a drying furnace to form a crude graphene powder;

[0027] S5: burning the crude graphene powder in an inert gas atmosphere for 3-4 hours to form graphene powder.

[0028] In a specific embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com