Metamifop intermediate and preparation method of metamifop

A technology of fenpyramid and fenpyral, which is applied in the field of preparation of fenpyral herbicides, can solve problems such as high production cost and unsatisfactory waste liquid treatment, and achieve reduction of decomposition and reduction of raw materials cost and waste water treatment cost, and the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

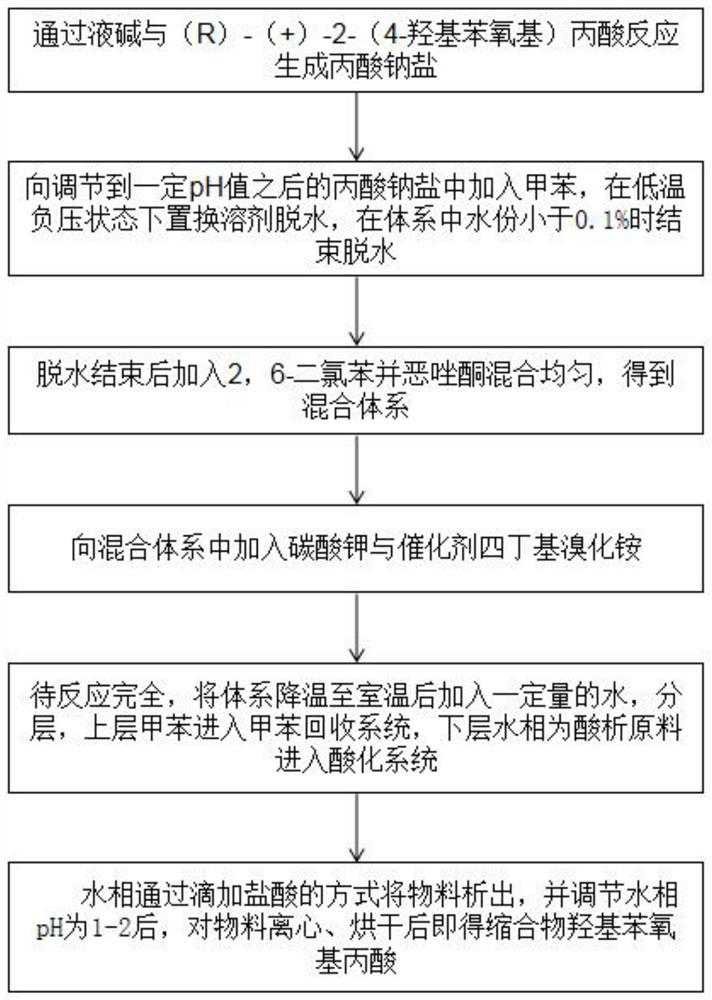

[0034] Please refer to the attached figure 1 , with figure 1 The embodiment of the application provided for the embodiment of the application provides a method for the preparation of an intermediate of fenpyramid, comprising the following steps:

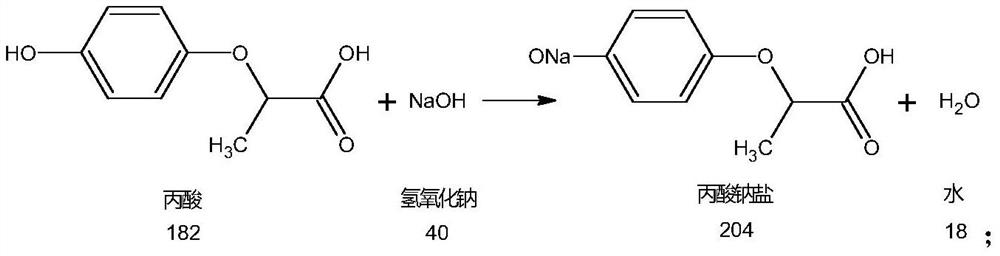

[0035] Generate propionic acid sodium salt by reaction of liquid caustic soda and (R)-(+)-2-(4-hydroxyphenoxy) propionic acid (hereinafter referred to as propionic acid), the reaction formula is as follows:

[0036]

[0037] Add toluene to the propionate sodium salt adjusted to a certain pH value, replace the solvent for dehydration under low temperature and negative pressure, and end the dehydration when the water content in the system is less than 0.1%;

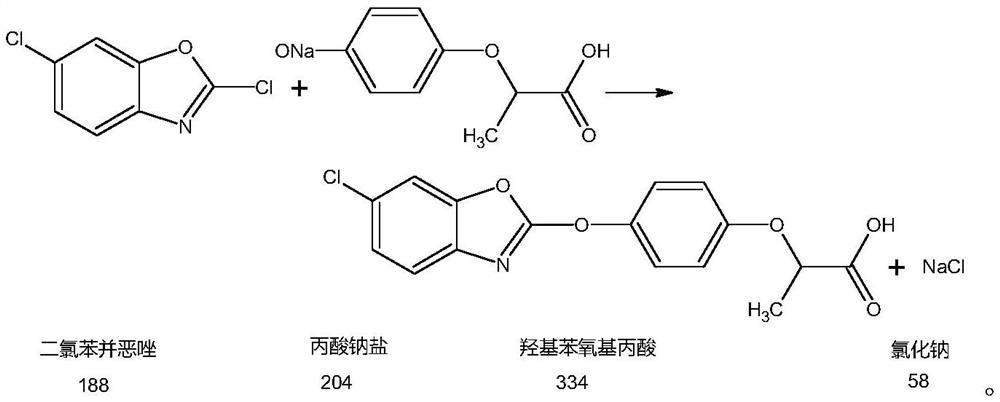

[0038] After the dehydration is completed, add 2,6-dichlorobenzoxazolone and mix evenly to obtain a mixed system;

[0039] Add salt of wormwood and catalyzer tetrabutyl ammonium bromide to mixing system by the mode of a small amount many times;

[0040] After the reaction is...

example 1

[0044] 1. Add 246.8g of 25% liquid caustic soda into a 1000ml four-neck flask and start stirring.

[0045] 2. Weigh 132.2g of propionic acid and add it to the liquid caustic soda several times in small amounts. The control time is 1 hour. After the dropwise addition, keep warm at 40-50°C for two hours, then take a sample and analyze that the propionic acid content is less than 0.1%. If the reaction is qualified, proceed to the next step.

[0046] 3. After adjusting the pH to 12 with 10% hydrochloric acid, add 400ml of toluene frame negative pressure oil-water separation device to dehydrate until the water content is less than 0.05%.

[0047] 4. After cooling down to room temperature, add 140.2 g of molten dichloride into the flask and stir evenly.

[0048] 5. Add 77.2g of potassium carbonate and 6g of tetrabutylammonium bromide through the feeding funnel for 1 hour.

[0049] 6. Raise the temperature to 80° C. and keep it warm for 8 hours to react. Sampling and analyzing the r...

example 2

[0055] 1. Add 246.5g of 25% liquid caustic soda into a 1000ml four-neck flask and start stirring.

[0056] 2. Weigh 132.4g of propionic acid and add it to the liquid caustic soda in small amounts for several times. The control time is 1 hour. After the dropwise addition, keep warm at 40-45°C for two hours, then take a sample and analyze that the propionic acid content is less than 0.1%. If the reaction is qualified, proceed to the next step.

[0057] 3. After adjusting the pH to 12 with 10% hydrochloric acid, add 400ml of toluene frame negative pressure oil-water separation device to dehydrate to 0.07% moisture.

[0058] 4. After cooling down to room temperature, add 140.3 g of molten dichloride into the flask and stir evenly.

[0059] 5. Add 77.0g of potassium carbonate and 6g of tetrabutylammonium bromide through the feeding funnel for 1 hour.

[0060] 6. Raise the temperature to 80° C. and keep it warm for 8 hours to react. Sampling and analyzing the residue of dichloride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com