Preparation method of red-orange-light blue-violet light conversion agent for agricultural film

A technology of light-changing agent and red-orange light, applied in chemical instruments and methods, luminescent materials, etc., can solve the problem that light-changing agricultural film cannot be widely used, the validity period is only 2-3 months, and the dispersion of light-changing agent is not good, etc. Problems, to achieve good compatibility with the organic phase of agricultural film, conducive to healthy growth, and can convert a wide range of ultraviolet light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Among them, red-orange fluorescent powder: 3.5MgO 0.5MgF 2 · GeO 2 :Mn x 4+ (0<x≤0.5);

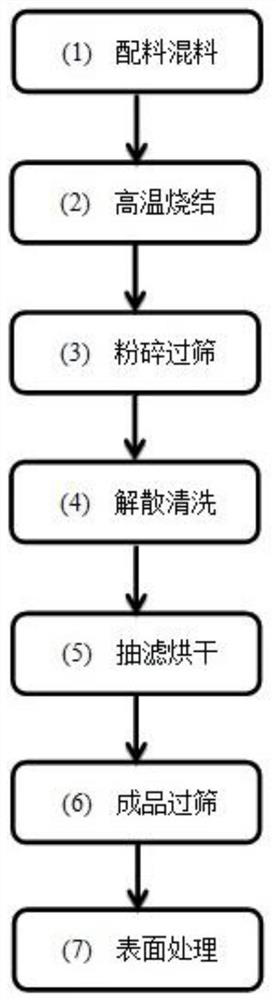

[0031] Preparation:

[0032] 1) Take x=0.15, weigh MgO and MgF respectively according to stoichiometric 2 、GeO 2 , MnCO 3 , fully mixed and evenly loaded into an alumina crucible, placed in a box-type air atmosphere furnace, burned at a temperature of 1120°C, and held for 8 hours.

[0033] 2) After cooling out of the furnace, pass through a 150-mesh sieve after crushing, and then use According to the ratio of ball to material = 2:1, the agate balls were ball milled and dissolved in a PVC material ball mill barrel, and the dissolution time was controlled for 30 minutes.

[0034] 3) After disbanding, transfer it to a PVC bucket, stir and wash it with deionized water for 3 times, then carry out vacuum filtration, and finally transfer it to a hot air circulation oven for drying at 120°C for 12 hours.

[0035] 4) After drying, the powder is cooled and passed through a 200-mesh ...

Embodiment 2

[0045] Among them, red-orange fluorescent powder: Y 2-x-y o 3 :Eu x 3+ m y (M=one or more of Gd, Bi, W, In, Ga, 0<x≤0.1, 0<y≤0.01);

[0046] Preparation:

[0047] 1) Take x=0.05, y=0.007, M=Gd, weigh Y respectively according to stoichiometric 2 o 3 、Eu 2 o 3 、Gd 2 o 3 , adding 0.3% by weight of SrB 4 o 7 As a flux, mix well and put it into an alumina crucible, place it in a box-type air atmosphere furnace, and burn it at 1300°C for 5 hours.

[0048] 2) After cooling out of the furnace, pass through a 150-mesh sieve after crushing, and then use According to the ratio of ball to material = 2:1, the agate balls were ball milled and dissolved in a PVC material ball mill barrel, and the dissolution time was controlled for 30 minutes.

[0049] 3) After disbanding, transfer it to a PVC bucket, stir and wash it with deionized water for 3 times, then carry out vacuum filtration, and finally transfer it to a hot air circulation oven for drying at 120°C for 12 hours.

[0...

Embodiment 3

[0060] Among them, the red-orange fluorescent powder: (Sr 1-x-y ,Mg y ) 3 (PO 4 ) 2 :Sn x 2+ (0

[0061] 1) Take x=0.05, y=0.10 and weigh SrCO respectively according to stoichiometry 3 , NH 4 h 2 PO 4 , SnO 2 , MgO, add 0.3% Li by weight 2 CO 3 As a flux, it is fully mixed and put into an alumina crucible and covered, placed in a box-type reduction furnace, reduced and burned at 1180°C under a 10% hydrogen reducing atmosphere, and the holding time is 5 hours.

[0062] 2) After cooling out of the furnace, pass through a 150-mesh sieve after crushing, and then use According to the ratio of ball to material = 1:1, the agate balls were ball milled and dissolved in a PVC material ball mill barrel, and the dissolution time was controlled for 30 minutes.

[0063] 3) After disbanding, transfer it to a PVC bucket, stir and wash it with deionized water for 3 times, then carry out vacuum filtration, and finally transfer it to a hot air circulation oven fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com