Preparation method of tungsten oxide/carbon flower-ball-shaped lithium battery composite negative electrode material

A negative electrode material, lithium battery technology, applied in battery electrodes, lithium storage batteries, negative electrodes, etc., can solve the problems of increasing production energy consumption and investment, unfavorable industrialization development, etc., saving energy consumption and equipment investment, and mild preparation conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a tungsten oxide / carbon flower-shaped lithium battery composite negative electrode material, comprising the steps of:

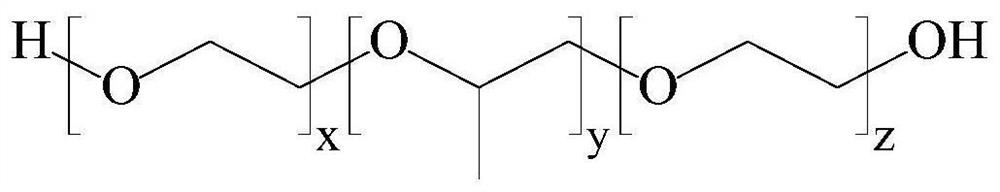

[0032] (1) Material preparation: Take polyether F127 with an average molecular weight of 2800 and dissolve it in 29mL of water to make polyether F127 aqueous solution, then dissolve soluble tungstate in polyether F127 aqueous solution to prepare tungstate and polyether Dispersion of F127; dissolving dopamine in deionized water to form a dopamine solution;

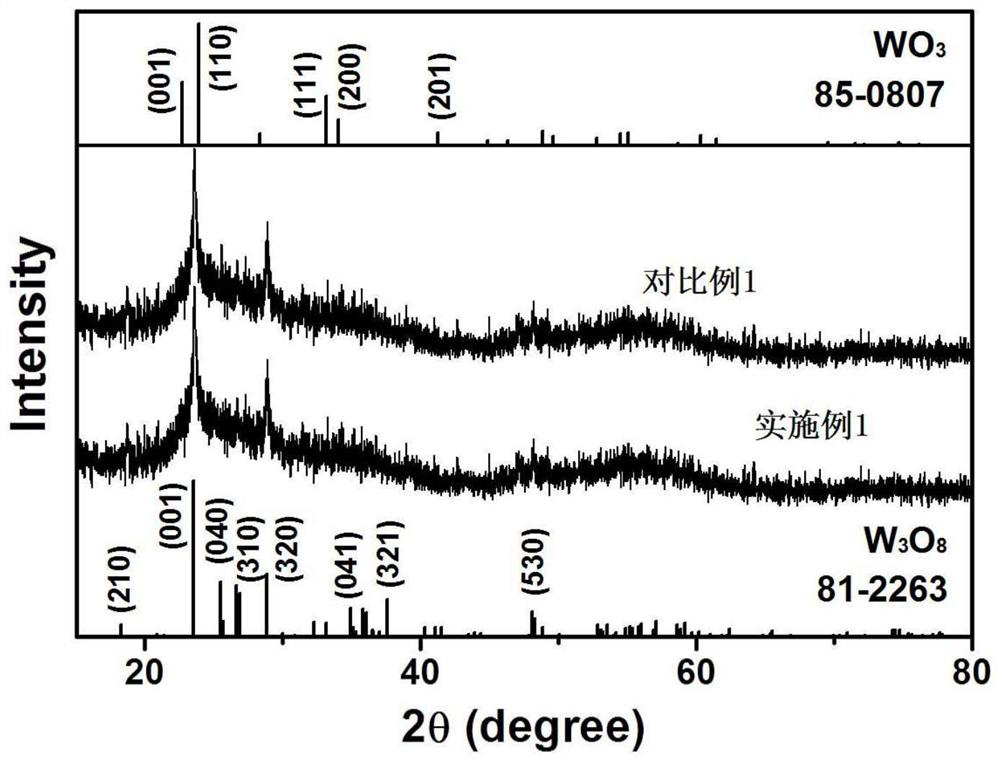

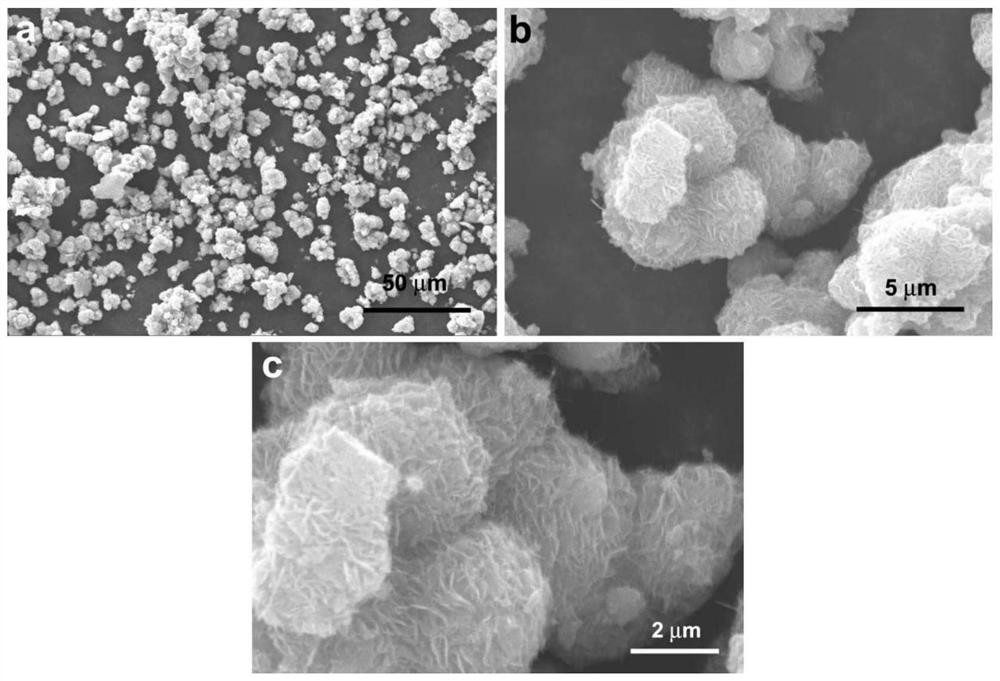

[0033] (2) Preparation of lithium battery anode material co-precipitated with tungsten and carbon precursors: Take dopamine solution and add it to the dispersion containing tungstate and polyether F127. At this time, the concentration of polyether F127 in the solution is 17g / L. The concentration of sodium tungstate was 1.2mmol / L, and the concentration of dopamine was 63mmol / L. The mixed reaction solution was prepared and stirred at 25°C for 24 hours. After the stirring was com...

Embodiment 2

[0043] A method for preparing a tungsten oxide / carbon flower-shaped lithium battery composite negative electrode material, comprising the steps of:

[0044] (1) Material preparation: Take polyether F127 with an average molecular weight of 1000 and dissolve it in 29mL of water to make polyether F127 aqueous solution, then dissolve soluble tungstate in polyether F127 aqueous solution to prepare tungstate and polyether Dispersion of F127; dissolving dopamine in deionized water to form a dopamine solution;

[0045] (2) Preparation of lithium battery negative electrode material co-precipitated with tungsten and carbon precursors: take dopamine solution and add it to the dispersion containing tungstate and polyether F127. At this time, the concentration of polyether F127 in the solution is 5g / L. The concentration of sodium tungstate was 0.5mmol / L, and the concentration of dopamine was 20mmol / L. The mixed reaction solution was prepared and stirred at 20°C for 20h. After stirring, it ...

Embodiment 3

[0049] A method for preparing a tungsten oxide / carbon flower-shaped lithium battery composite negative electrode material, comprising the steps of:

[0050] (1) Material preparation: Dissolve polyether F127 with an average molecular weight of 15,000 in 29mL of water to make a polyether F127 aqueous solution, and then dissolve soluble tungstate in the polyether F127 aqueous solution to prepare tungstate and polyether Dispersion of F127; dissolving dopamine in deionized water to form a dopamine solution;

[0051] (2) Preparation of lithium battery negative electrode material co-precipitated with tungsten and carbon precursors: take dopamine solution and add it to the dispersion containing tungstate and polyether F127. At this time, the concentration of polyether F127 in the solution is 50g / L. The concentration of sodium tungstate was 5mmol / L, and the concentration of dopamine was 100mmol / L. The mixed reaction solution was prepared and stirred at 35°C for 5h. After the stirring w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com