Vapor phase corrosion inhibition

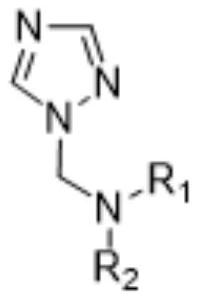

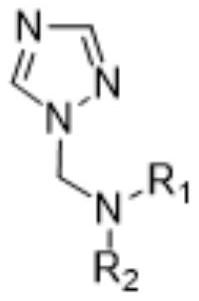

A corrosive, azole compound technology, used in additives, lubricating compositions, petroleum industry, etc., can solve problems such as unprotected electronic devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0079] Sample Preparation - General procedure for coupling azoles to alkylamines using paraformaldehyde: combine 1.0 moles of azole with 1.0 moles of alkylamine or dialkylamine and heat the mixture to 60- 80°C. Then 0.94 to 1.0 equivalents of paraformaldehyde were added. For low mw amines, the paraformaldehyde charge is divided into two equal parts and the second part is not charged until the reaction exotherm from the first charge subsides. The equivalent weight of paraformaldehyde is calculated as follows:

[0080] Eq wt=30.0264 / (CH in paraformaldehyde 2 =wt% of O)

[0081] Once the exotherm from the paraformaldehyde addition had subsided, heating was continued until all solids had dissolved. Vacuum was then applied to the reaction mixture to remove water, a by-product of the reaction. No further purification of the product was required. Samples prepared by this method are provided below.

[0082] Sample 1: A commercial sample of 1,2,4-triazole was obtained from Tokyo...

example 1

[0106] Example 1: Several sample corrosion inhibitors were incorporated at a level of 500 ppm into Formulation A without tolyltriazole (listed as "Baseline" in Table 1). The semi-submersion test was performed on each of these fluids at 65°C for seven days. The ASTM D130 ratings for both the liquid space portion and the vapor space portion of each coupon are shown in Table 1 below.

[0107] Table 1

[0108]

example 2

[0109] Example 2: The performance of three sample corrosion inhibitors in the semi-submersion test as a function of the treatment level of Formulation A without tolyltriazole is shown in Table 2. The semi-submersion test was performed at 80°C for seven days. ASTM D130 ratings are listed for both liquid and vapor spaces (front only).

[0110] Table 2

[0111]

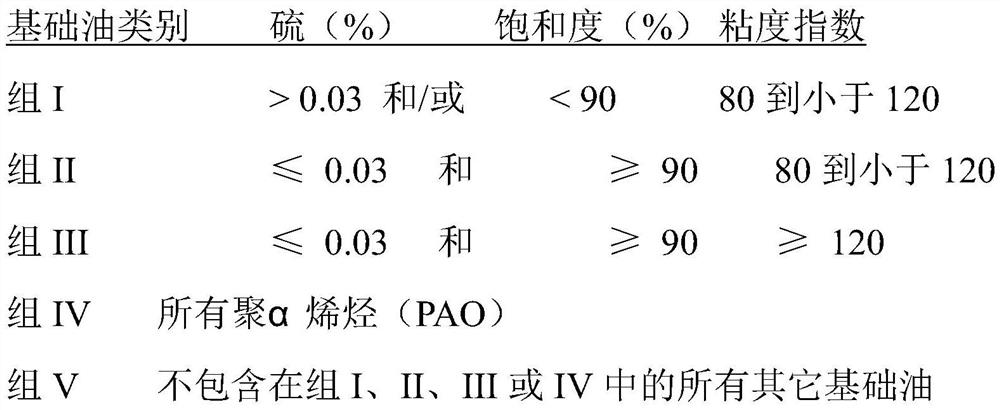

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com