Deodorized and decolorized sea cucumber powder and preparation method thereof

A sea cucumber powder and decolorization technology, applied in the directions of dairy products, milk preparations, milk substitutes, etc., can solve the problems of cumbersome extraction technology of sea cucumber active substances, waste of sea cucumber resources, etc. time cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

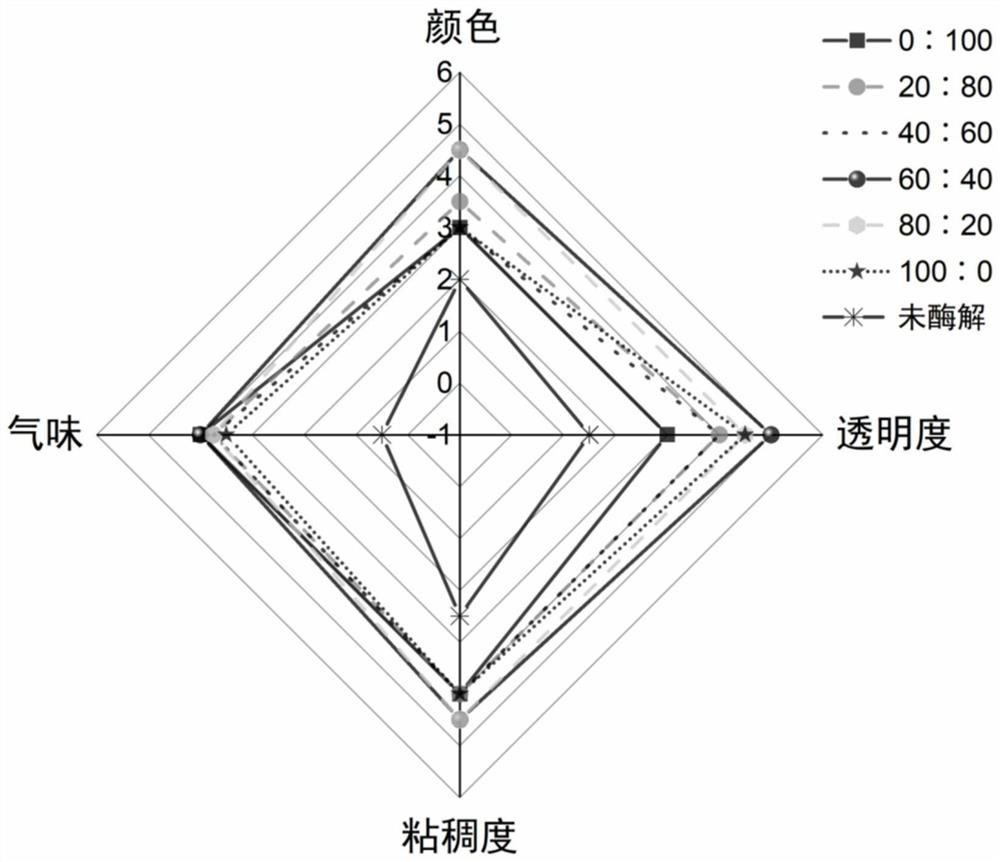

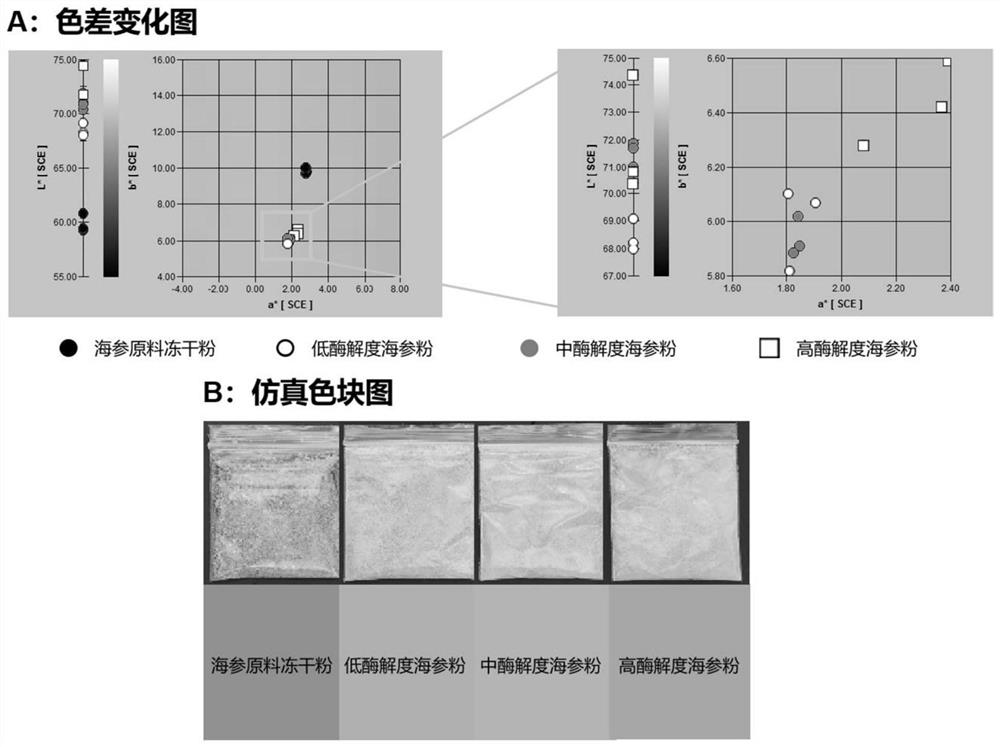

[0076] Embodiment 1: the preparation of sea cucumber powder (LDH) with low degree of enzymolysis

[0077] The preparation method of sea cucumber powder (LDH) with low enzymolysis degree comprises the steps:

[0078] (1) Cut open the fresh sea cucumber from the abdomen, remove internal organs and gonads, soak in clean water for 3-5 minutes, and then wash the inner and outer surfaces of the sea cucumber body wall with running water;

[0079] (2) Drain the washed sea cucumber body wall, cut it into small pieces (1~2)cm×(1~2)cm and put it in a multifunctional blender, which does not exceed 80% of the volume of the container. Under the condition of water, stir at low speed for homogenization for 1 min;

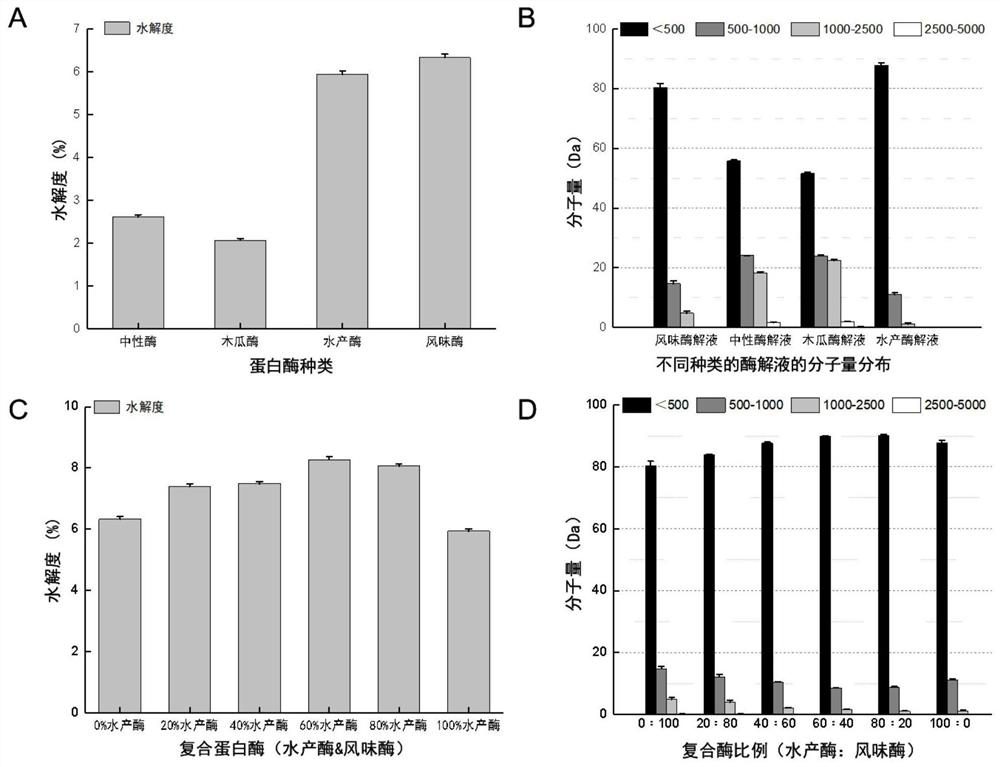

[0080] (3) Take 160g of homogenate and add it to the fermentation bottle, then add 640g of water and 112000U compound enzyme (67200U special enzyme for aquatic products + 44800U flavor protease), the enzymolysis temperature is 50-55°C, and the pH is natural pH (6.5-7.5), Enzyme h...

Embodiment 2

[0086] Embodiment 2: the preparation of sea cucumber powder (MDH) in the degree of enzymatic hydrolysis

[0087] Sea cucumber powder was prepared by the method of Example 1, the only difference being that the enzymatic hydrolysis time was 30 minutes, and other steps were the same as in Example 1 to obtain the finished sea cucumber powder.

Embodiment 3

[0088] Embodiment 3: the preparation of high degree of enzymolysis sea cucumber powder (HDH)

[0089] Sea cucumber powder was prepared by the method of Example 1, the only difference being that the enzymatic hydrolysis time was 5 hours, other steps were the same as in Example 1, and the sea cucumber powder was a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com