A method of laser bending and forming of knife switch knife holder seat

A knife switch and bending forming technology, which is applied to forming tools, metal processing equipment, manufacturing tools, etc., to achieve the effects of reducing manufacturing costs, saving copper consumption, and shortening the research and development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Embodiment: The process of laser bending and forming the sample of the knife switch knife holder seat of the copper-steel laminate.

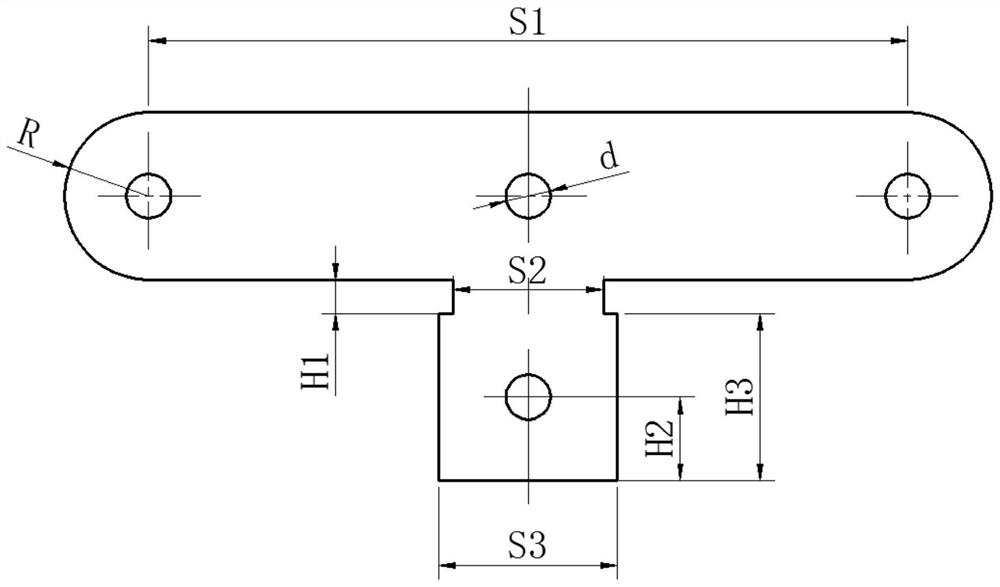

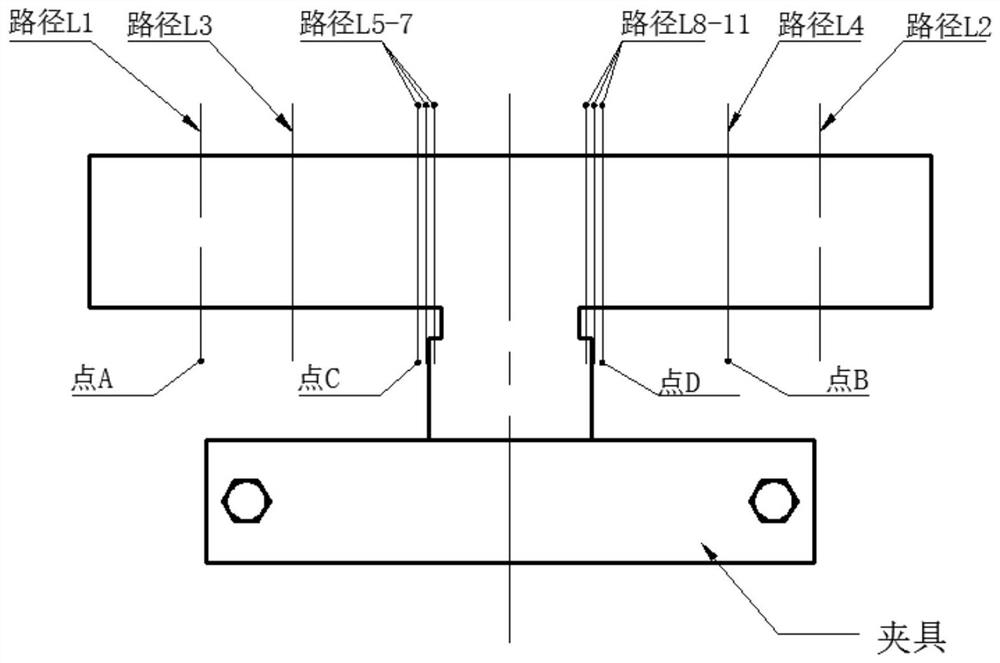

[0033] (1) Use laser to cut 1mm thick copper-steel laminate into 68mm for S1, 13.5mm for S2, 16mm for S3, 7.5mm for R, 3mm for H1, 7.5mm for H2, 15mm for H3, the diameter of 4 holes d is 4mm, and its size distribution is as follows figure 1 shown. The path distribution of the sample is the same as figure 2 , where paths L1 and L2 are 11mm from both ends, paths L3 and L4 are 9mm from paths L1 and L2, paths L5 and L8 are 13.2mm from paths L3 and L4, paths L5~L7 are connected with paths L8~ The distance between L10 is 0.8 mm, and the path L11 and the path L9 are located at the same position.

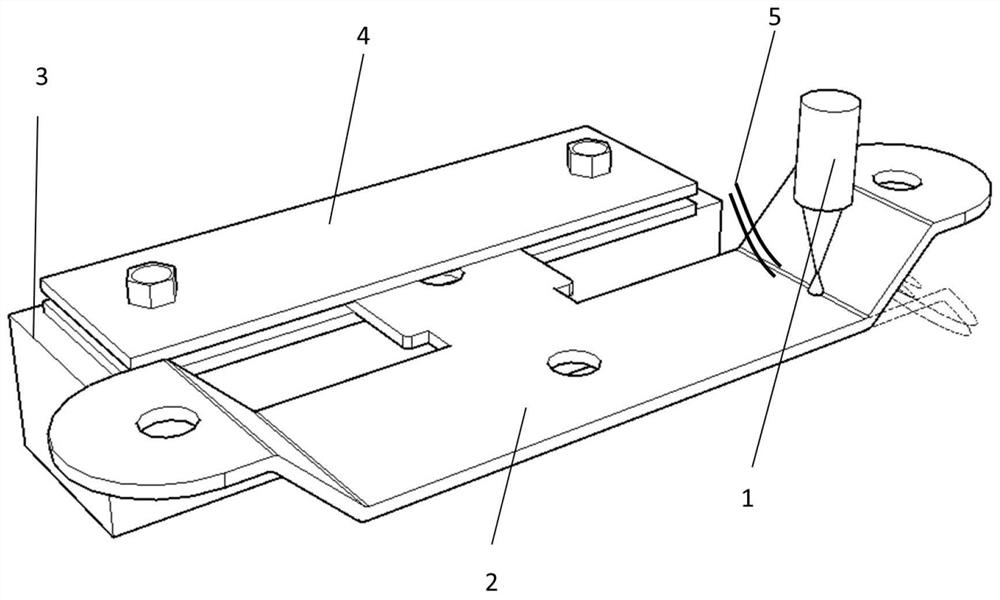

[0034] (2) Clamp the clamping part in the middle of the rough plate 2 with the clamp 4, and place it horizontally on the laser processing workbench.

[0035] (3) Adjust the position of the laser head 1 to find the scanning reference point A; set t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com