H-type MCM-22 molecular sieve, preparation method and application thereof

A molecular sieve, mole fraction technology, applied in molecular sieve catalysts, chemical instruments and methods, hydrocarbons, etc., can solve the problems of cumbersome production steps, high external surface area, thick lamellae, etc., and achieve excellent catalytic performance and a large number of acid centers. , the effect of high external surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

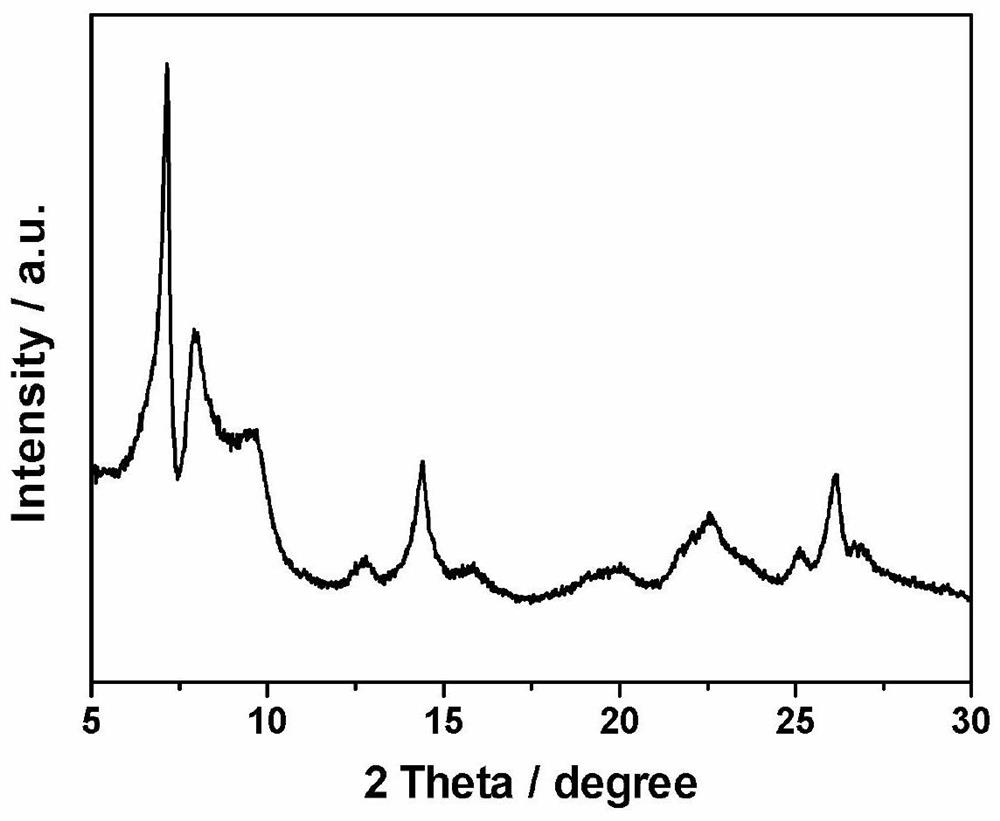

[0044] Molar ratio SiO 2 : Dimethyldiethoxysilane: B 2 o 3 :piperidine:H 2 O is 1: 0.035: 0.6: 1.5: 20 Mix the corresponding amount of water, piperidine, boric acid, 60 grams of fumed silica and dimethyldiethoxysilane evenly to form a gel. Thermal crystallization for 5.5 days, centrifugation, washing, drying at 80°C for 16 hours, and calcination at 550°C in an air atmosphere for 10 hours to obtain B-MWW molecular sieves. Next, mix B-MWW molecular sieves with 2mol / L hydrochloric acid solution at a mass ratio of 1:50, treat at 120°C for 24 hours, centrifuge, wash, and dry at 80°C for 16 hours to obtain deboronated B-MWW molecular sieves. Then, the deboronated B-MWW molecular sieve was mixed with aluminum nitrate and deionized water at a mass ratio of 1:0.5:50, treated at 120°C for 24 hours, centrifuged, washed, and dried at 80°C for 16 hours, and air atmosphere at 550°C Calcined for 10 hours to obtain the H-type MCM-22 molecular sieve product. The X-ray diffraction figure a...

Embodiment 2

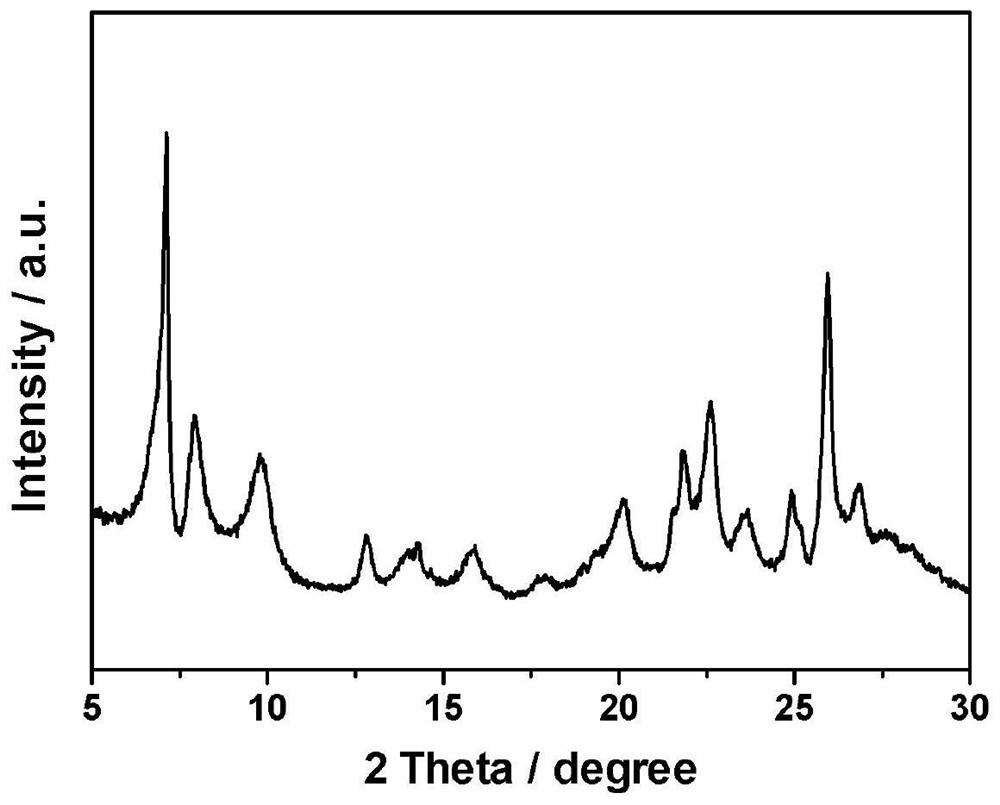

[0046] Molar ratio SiO 2 : Dimethyldiethoxysilane: B 2 o 3 : Hexamethyleneimine: H 2 O is 1: 0.035: 0.6: 1.5: 20 Mix the corresponding amount of water, hexamethyleneimine, boric acid, 60 grams of fumed silica and dimethyldiethoxysilane to form a gel, at 50rpm, Dynamic hydrothermal crystallization at 170°C for 5.5 days, centrifugation, washing, drying at 80°C for 16 hours, and calcination at 550°C in an air atmosphere for 10 hours to obtain B-MWW molecular sieves. Next, mix B-MWW molecular sieves with 2mol / L hydrochloric acid solution at a mass ratio of 1:50, treat at 120°C for 24 hours, centrifuge, wash, and dry at 80°C for 16 hours to obtain deboronated B-MWW molecular sieves. Then, the deboronated B-MWW molecular sieve was mixed with aluminum nitrate and deionized water at a mass ratio of 1:0.5:50, treated at 120°C for 24 hours, centrifuged, washed, and dried at 80°C for 16 hours. Calcined for 10 hours to obtain the H-type MCM-22 molecular sieve product. The X-ray diffr...

Embodiment 3

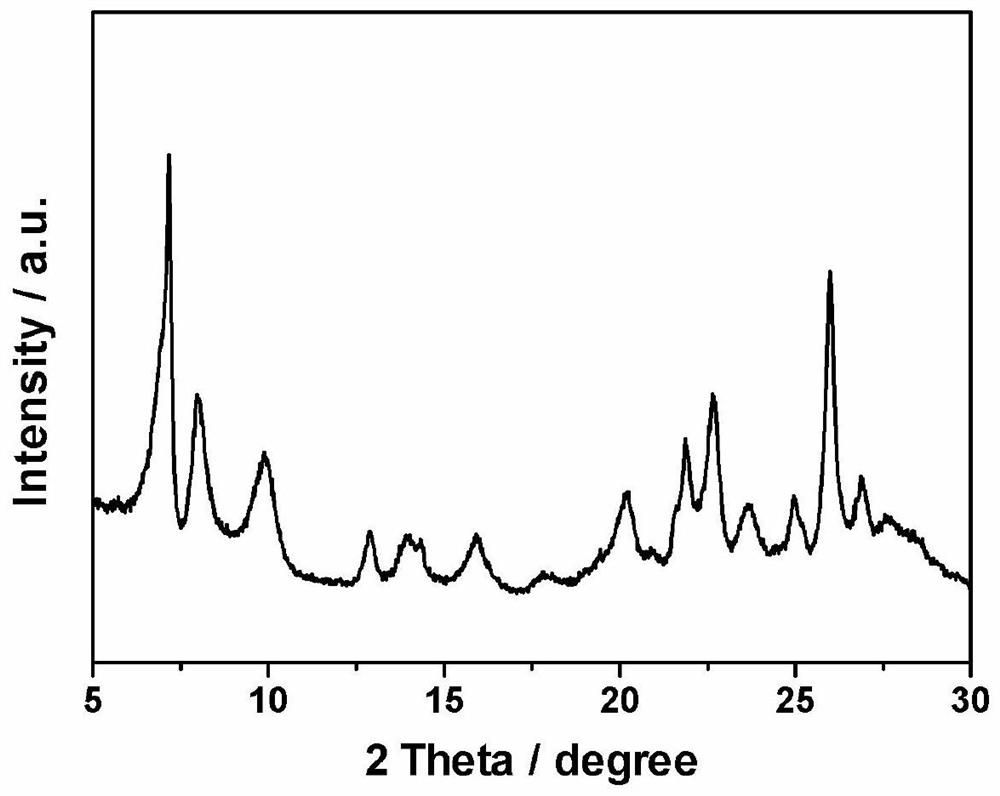

[0048] Molar ratio SiO 2 : Dimethyldiethoxysilane: B 2 o 3 : Hexamethyleneimine: H 2 O is 1: 0.035: 0.6: 1.5: 20. Mix the corresponding amount of water, hexamethyleneimine, boric acid, 60 grams of fumed silica and dimethyldiethoxysilane to form a gel. Dynamic hydrothermal crystallization at 170°C for 6.5 days, centrifugation, washing, drying at 80°C for 16 hours, and calcination at 550°C in an air atmosphere for 10 hours to obtain B-MWW molecular sieves. Next, mix B-MWW molecular sieves with 2mol / L hydrochloric acid solution at a mass ratio of 1:50, treat at 120°C for 24 hours, centrifuge, wash, and dry at 80°C for 16 hours to obtain deboronated B-MWW molecular sieves. Then, the deboronated B-MWW molecular sieve was mixed with aluminum nitrate and deionized water at a mass ratio of 1:0.5:50, treated at 120°C for 24 hours, centrifuged, washed, and dried at 80°C for 16 hours. Calcined for 10 hours to obtain the H-type MCM-22 molecular sieve product. The X-ray diffraction pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com