A kind of ultra-flat glaze for ceramic tile, ceramic tile and manufacturing method thereof

A manufacturing method and technology of ceramic tiles, applied in the field of porcelain tile production, can solve the problems of low quality rate of finished ceramic tiles, lack of glaze, corrugation, etc., and achieve the effects of improving the rate of finished products, avoiding lack of glaze, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

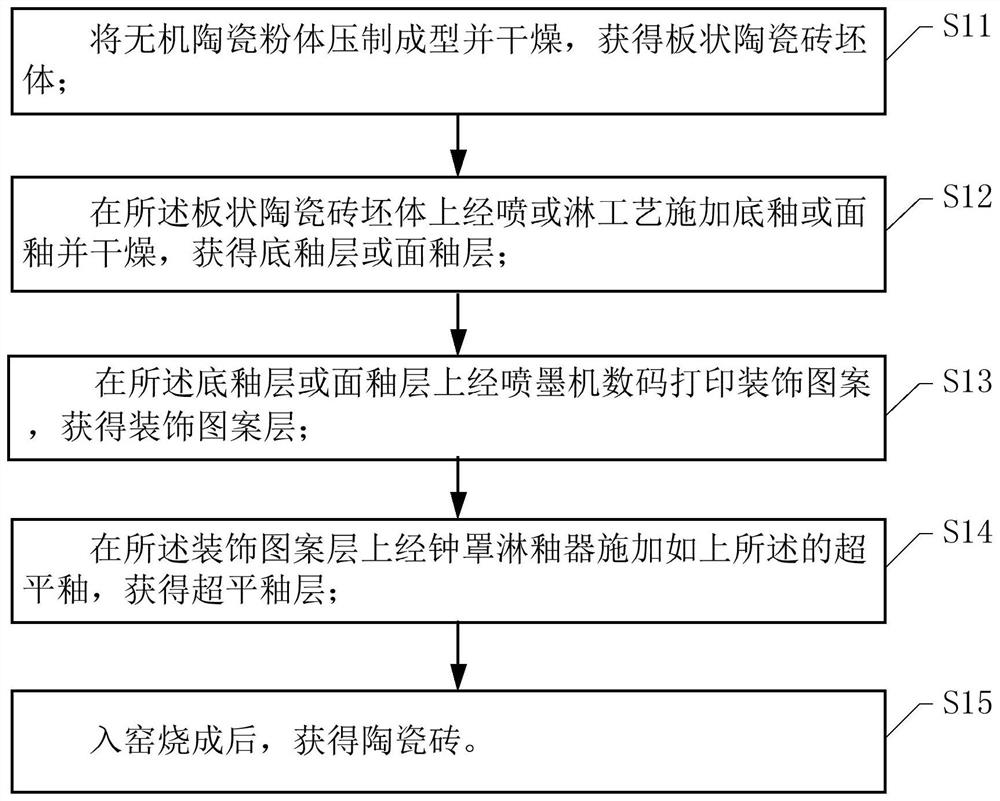

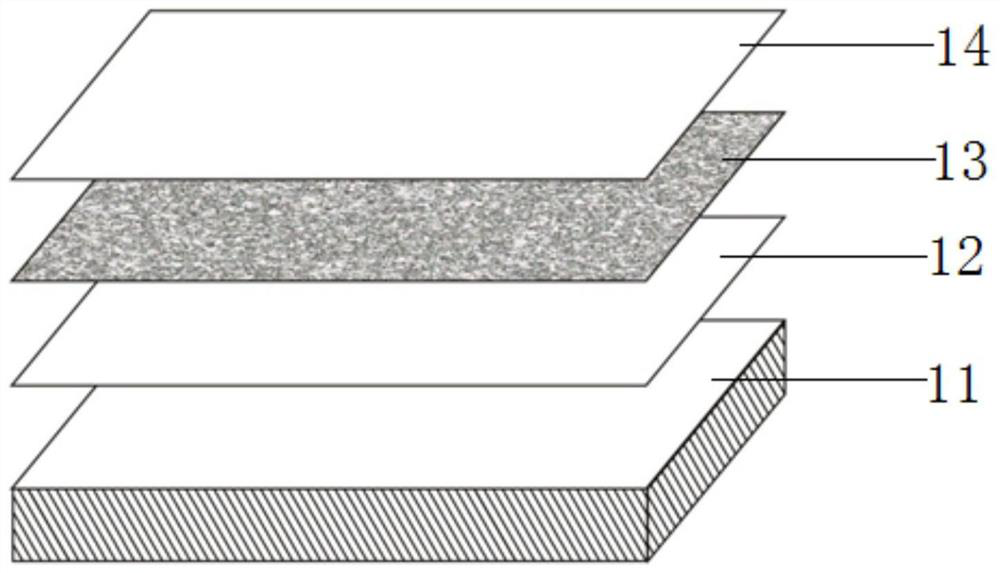

Method used

Image

Examples

Embodiment 1

[0080] The present embodiment provides an ultra-flat glaze for ceramic tiles, wherein the ultra-flat glaze comprises in mass percentage:

[0081] Organic solvent 20%~40%;

[0082] Inorganic ceramic powder 40% to 70%;

[0083] Polymer organic dispersant 8% to 25%.

[0084] The raw materials of the inorganic ceramic powder, in terms of weight fraction, include:

[0085] 1-3 parts of zinc oxide; 8-12 parts of barium carbonate; 30-50 parts of feldspar; 6-15 parts of sintered talc; 6-15 parts of frit; 6-15 parts of kaolin; 6-8 parts of calcined kaolin; carbonic acid Calcium 6 to 10 servings.

[0086] The viscosity of the organic solvent at 40°C is 2-8 mPa·S;

[0087] The organic solvent includes isopropyl laurate, isooctyl laurate, isopropyl myristate, isooctyl palmitate, isopropyl palmitate, dipropylene glycol methyl ether acetate, tripropylene glycol methyl ether, tripropylene glycol Monobutyl ether, isotridecanol ethoxylate or white oil;

[0088]The macromolecular organic ...

Embodiment 2

[0092] The present embodiment provides an ultra-flat glaze for ceramic tiles, which is different from the ultra-flat glaze for ceramic tiles provided in the first embodiment above:

[0093] The raw materials of the inorganic ceramic powder are in weight fraction, and specifically include:

[0094] 2 parts of zinc oxide; 12 parts of barium carbonate; 42 parts of feldspar; 10 parts of sintered talc; 10 parts of frit; 8 parts of kaolin; 8 parts of calcined kaolin; 8 parts of calcium carbonate.

Embodiment 3

[0096] The present embodiment provides an ultra-flat glaze for ceramic tiles, which is different from the ultra-flat glaze for ceramic tiles provided in the first embodiment above:

[0097] The chemical composition of the inorganic ceramic powder is in mass percentage, including:

[0098] SiO 2 45%~65%; Al 2 O 3 10%~20%; Fe 2 O 3 0~0.5%; CaO 4%~10%; MgO3%~10%; K 2 O 0~2%; Na 2 O 4%~8%; ZnO 1%~3%; BaO 8%~15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com