Method for preparing expanded microspheres under normal pressure through visible light initiation

A technology of expanding microspheres and visible light, which is applied to the preparation of expanded microspheres by visible light-induced suspension polymerization and the preparation of expanded microspheres, can solve the problems of harsh polymerization conditions, low foaming ratio of microspheres, uncontrollable molecular weight distribution range, etc. Controllable reaction, good hydrophilic and lipophilic properties, and the effect of short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

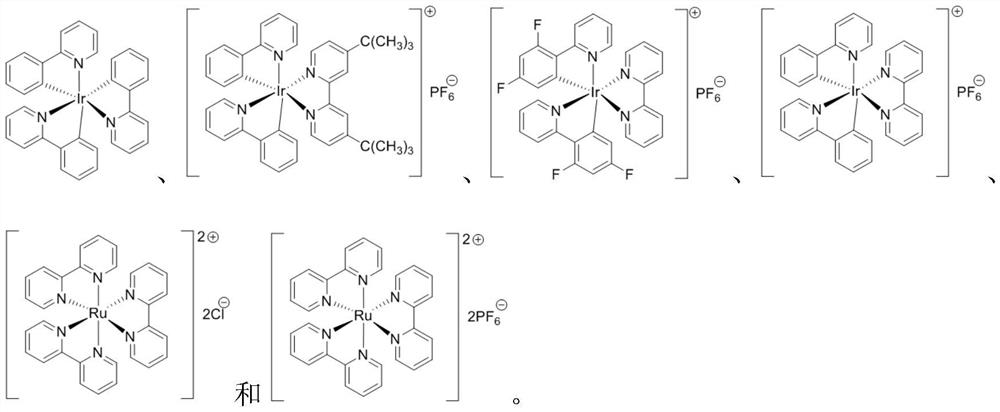

[0092] In 600g of deionized water, add 40g of colloidal silicon dioxide with an active ingredient of 30%, 1g of KURARAY POVAL48-80 and 1g of EDTA·4Na, stir the resulting mixture evenly to obtain an aqueous dispersion medium, and adjust the pH value to 4.5. Mix AN (60.0g), MAN (80.0g), MMA (50.0g), MAA (10.0g), EGDMA (0.4g), IP (70.0g), photosensitizer 1 (20.0g), DDMA-GMA (82.31 g) mixing evenly to prepare an oil phase mixture.

[0093] The aqueous dispersion medium and the oily mixture were mixed and cooled to 5-10° C., and the resulting mixture was dispersed at a speed of 7000 rpm for 3 minutes using a homomixer (manufactured by PRIMIX, TK homomixer) to prepare a suspension. The suspension was transferred to a round bottom flask with a capacity of 2.0 L, and after nitrogen substitution, the reactant was stirred under the irradiation of a 30W white LED, etc., and reacted and polymerized at 25°C for 4 hours, and the resulting product was filtered and dried to obtain expandable...

Embodiment 2~6

[0095] The specific steps are as in Example 1, and the amount of raw materials is adjusted, as shown in Table 1.

[0096] Table 1

[0097]

[0098]

[0099] Compared with the previous preparation method of expanded microspheres, the present invention can quickly prepare expanded microspheres at normal temperature and pressure, and has the advantages of simple operation, mild reaction conditions, fast polymerization rate, high monomer conversion rate and low monomer residual content. Low, do not use sodium chloride in the reaction formula and other advantages.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com