Lubricating cutting fluid

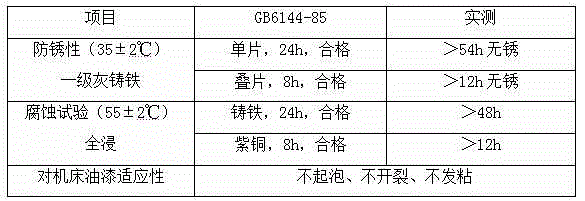

A cutting fluid and lubricity technology, applied in the direction of lubricating composition, etc., can solve the problems of precipitation or stratification, oil separation, poor bacterial resistance, poor anti-rust effect, etc., to achieve excellent lubrication, reduce friction, and improve anti-corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A lubricating cutting fluid is characterized in that it is made up of the following raw materials in parts by weight:

[0020] Methacrylic acid 4, di-n-butyl phosphite 5, isopropyl myristate 3, 1-hydroxybenzotriazole 2, stearic acid 2, barium ricinoleate 3, amino trimethylene phosphonic acid 0.8, dimethyl Aminopropylamine 0.2, naphthenic oil 4, neutral barium dinonyl naphthalene sulfonate 3, dialkyl p-diphenol 0.2, deionized water 80, rare earth functional additive 6, polyethylene oxide 2;

[0021] Described rare earth functional additive is made up of the following raw materials of weight part:

[0022] Lanthanum sulfate 3, octoxynol 2, sodium alkylbenzene sulfonate 2, divinylbenzene 0.2, alkenyl succinate 4, trimethylolpropane 0.7, lanolin 3, nano silicon dioxide 1-2 , deionized water 200, polyethylene glycol 400014;

[0023] Mix polyethylene glycol 4000 and lanolin into the reactor, heat and melt, adjust the temperature of the reactor to 120°C, add alkenyl succinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com