Rapid forming device for ultra-high-molecular-weight polymer

A technology of ultra-high molecular weight and molding devices, which is applied in the direction of manufacturing auxiliary devices, additive manufacturing, processing platforms/substrates, etc., can solve the problems of narrow processing temperature range, limited application occasions, and poor fluidity of ultra-high molecular weight polymers, and achieve printing The molding structure is flexible and changeable, the effect of adapting to a large span of temperature range and strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

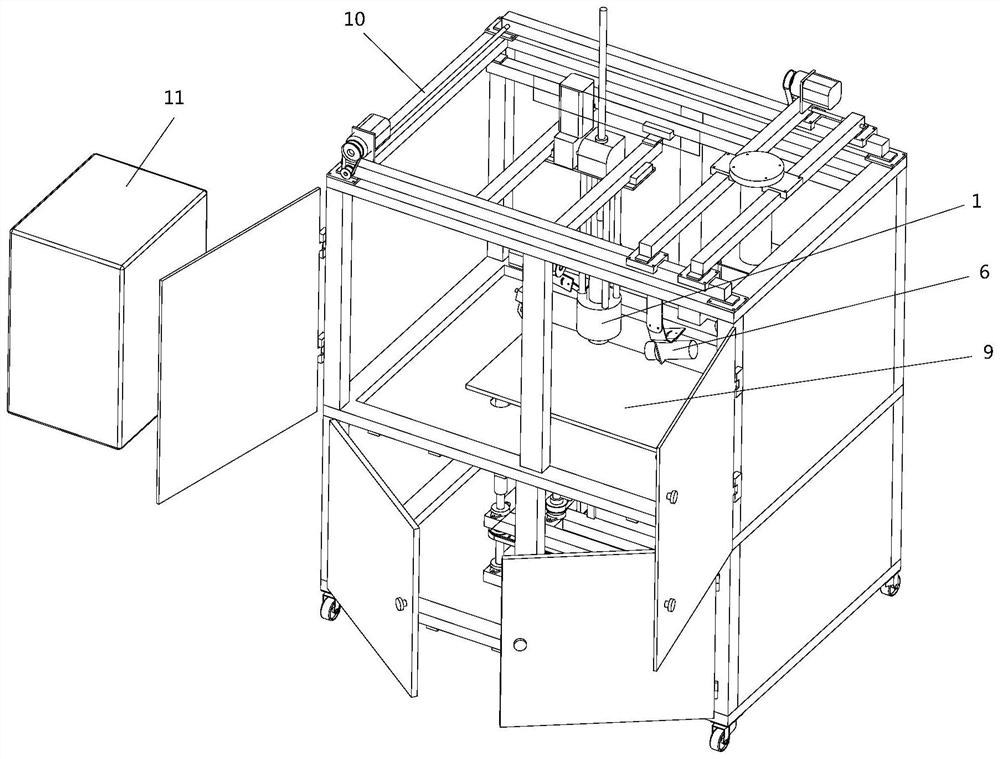

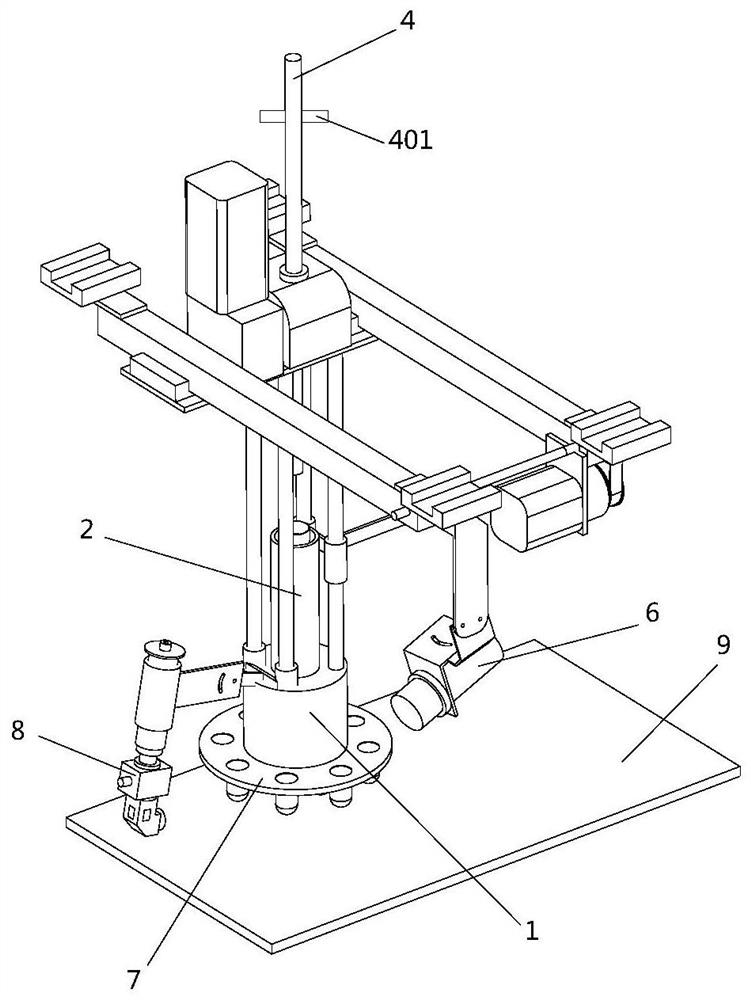

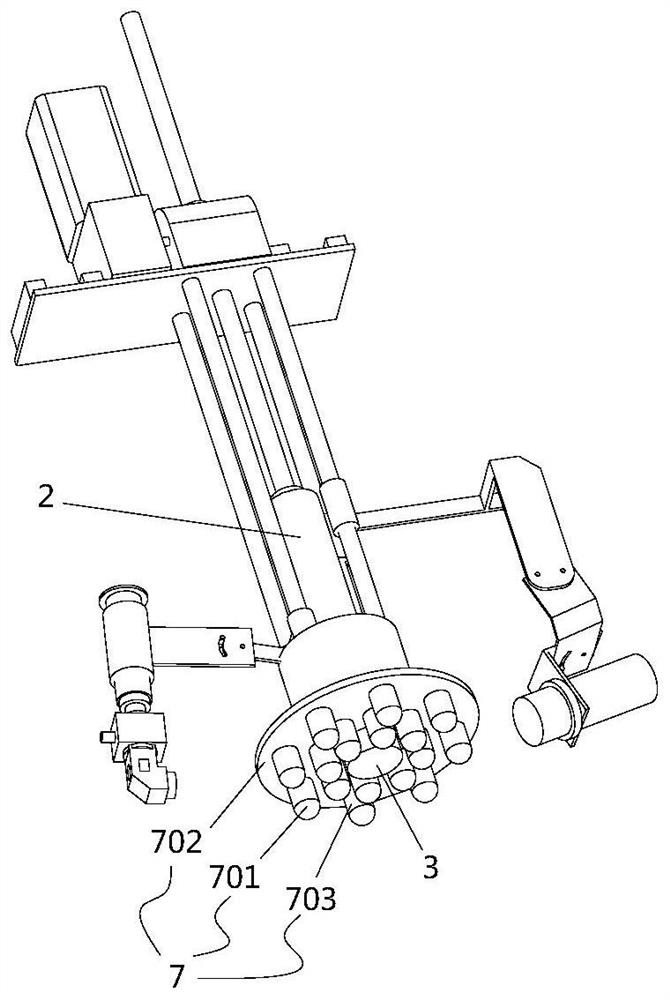

[0087] Such as Figure 1 to Figure 5 As shown, a high molecular weight polymer rapid prototyping device 1 described in this embodiment includes a silo 2, and a nozzle 3 arranged at the bottom of the silo 2; a heating module 5 formed from the silo 2 The heating zone where the temperature gradually increases from the top to the bottom nozzle 3 side; the feeding rod 4 cooperates with the silo 2 and reciprocates in the hopper 2 along the axial direction of the feeding rod 4; Inside the silo 2, corresponding to the heating zone, a first feeding chamber 201, a second feeding chamber 202 and a third feeding chamber 203 are provided; the first feeding chamber 201, the second feeding chamber 202 and the The cross-sectional area of the third feeding chamber 203 along the radial direction of the silo 2 gradually decreases.

[0088] The invention adopts high-temperature melting method to heat the ultra-high molecular weight polymer to a molten state and then extrude it into shape. The...

Embodiment 2

[0090] Such as Figure 1 to Figure 5 As shown, this embodiment is based on the first embodiment above. The first feeding chamber 201 in this embodiment is arranged inside the silo 2; at least two of the second feeding chambers 202 are arranged in the The inside of the silo 2 communicates with the first feeding cavity 201 ; at least two of the third feeding cavities 203 are arranged inside the silo 2 and communicates with the second feeding cavity 202 .

Embodiment 3

[0092] Such as Figure 1 to Figure 5 As shown, this embodiment is based on the above-mentioned embodiment 1 or embodiment 2, the first feeding chamber 201, the second feeding chamber 202 and the third feeding chamber 203 in this embodiment are cylindrical structures; The diameter of the first feeding chamber 201 is between 20 and 30 mm, and the length is between 100 and 200 mm; the diameter of the second feeding chamber 202 is between 4 and 10 mm, and the length is between 15 and 45 mm ; The diameter of the third feeding cavity 203 is between 2.5 and 6 mm, and the length is between 50 and 90 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com