ADN/AlH3 composite microsphere, preparation method and solid propellant containing microsphere

A technology of solid propellants and composite microspheres, which is applied in offensive equipment, explosives processing equipment, explosives, etc., can solve the problems of reduced hydrogen content, failure to meet the safety performance of propellants, and non-dense surface coating to achieve compact structure, Improve drug performance and safety performance, low mechanical sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

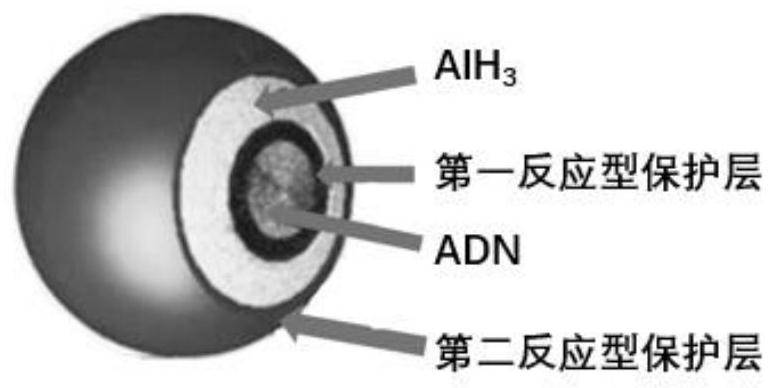

[0057] Ammonium dinitramide / aluminum trihydride (ADN / AlH) of the present invention 3 ) The preparation method of composite microspheres is to combine precipitation by in situ self-assembly method, comprising the following steps:

[0058] (1) After dissolving ADN in the solvent, add the precursor of the first reactive protective layer and stir evenly for later use. The first reactive protective layer includes a prepolymer, a curing agent, and a catalyst, and the stirring time is 20 to 30 minutes , the rotation speed is 400-800rpm, the prepolymer is one of hydroxyl-terminated glycidyl ether (GAP), hydroxyl-terminated polybutadiene (HTPB) or hydroxyl-terminated perfluoropolyether (PFPE), and the curing agent is Isophor One or a combination of ketone diisocyanate (IPDI), toluene diisocyanate (TDI) or polyfunctional aliphatic isocyanate (N-100), the catalyst is di-n-butyltin dilaurate.

[0059] (2) AlH 3 Put it into a beaker, add anti-solvent, and ultrasonically pulverize it in a...

Embodiment 1

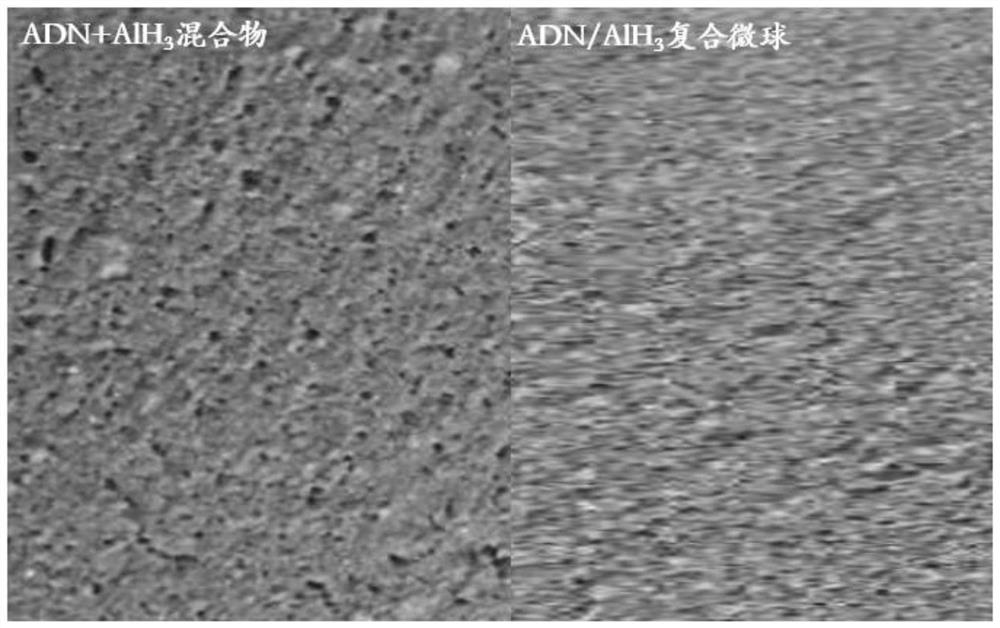

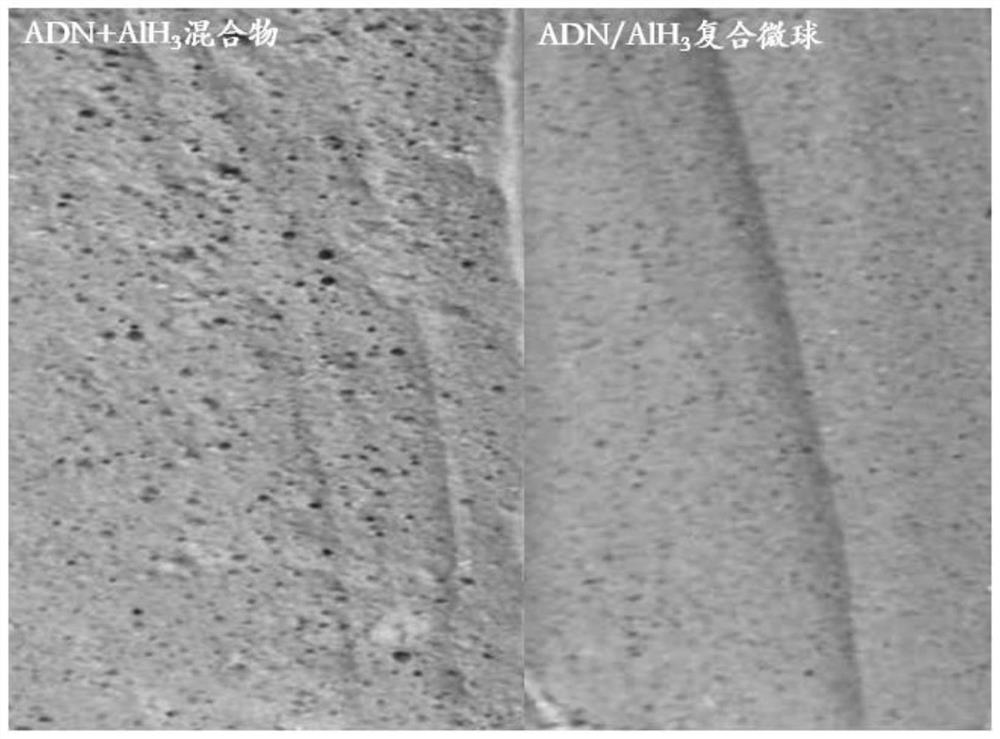

[0088] Dissolve 5g of ADN and 0.2g of HTPB glue + TDI curing agent + organotin catalyst in 20mL of acetonitrile; 5g of AlH 3 Put it into a beaker, add 100ml of anti-solvent dichloromethane, under the double action of stirring and ultrasonic, keep AlH 3 In a suspension state, the ultrasonic power is 700W, and the stirring speed is 1000rpm; the ADN solution is added dropwise at a rate of 0.2ml / min to a concentration of 5gAlH 3 Keep the temperature at 40°C, the ultrasonic power at 700W, and the stirring speed at 1000rpm, and react for 3 hours; then add 20mL of acetonitrile solution containing 0.5g of HTPB glue + TDI curing agent + organotin catalyst Add to the above solution, continue to react for 12h, cool to room temperature, filter, and vacuum dry to obtain off-white ADN / AlH 3 Composite energetic microspheres. Take 5gADN / AlH 3 Composite energetic microspheres and 5g of ADN and AlH3 mixture with a mass ratio of 1:1 were tested for hygroscopicity at a relative humidity of 75%...

Embodiment 2

[0090] Dissolve 8g of ADN and 0.12g of GAP glue + TDI curing agent + organotin catalyst in 20mL of acetone; 4g of AlH 3 Put it into a beaker, add anti-solvent cyclohexane 100ml, under the double action of stirring and ultrasonic, keep AlH 3 In a suspension state, the ultrasonic power is 700W, and the stirring speed is 800rpm; the ADN solution is added dropwise at a rate of 0.5ml / min to a concentration of 4gAlH 3 In the cyclohexane dispersion, keep the temperature at 50°C, the ultrasonic power is 700W, the stirring speed is 800rpm, and react for 3h; then add 20mL of acetone solution containing 0.6g of PFPE glue + TDI curing agent + organotin catalyst Add to the above solution, continue to react for 8h, cool to room temperature, filter, and vacuum dry to obtain off-white ADN / AlH 3 Composite energetic microspheres. Take 5gADN / AlH 3 Composite energetic microspheres and 5g of ADN and AlH with a mass ratio of 2:1 3 The mixture was tested for hygroscopicity at a relative humidity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com