adn/alh 3 Composite microsphere, preparation method and solid propellant comprising same

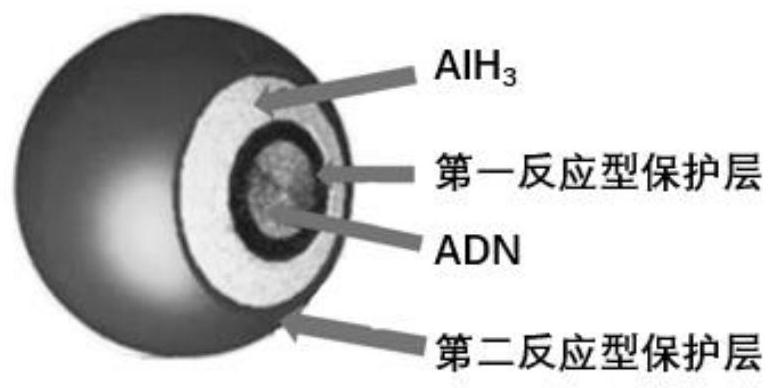

A technology of composite microspheres and curing agents, which is applied in the direction of offensive equipment, explosives processing equipment, explosives, etc., can solve the problems of non-dense surface coating, decreased hydrogen content, and failure to meet the safety performance of propellants, achieving low mechanical sensitivity, The effect of tight structure and controllable microsphere structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] Ammonium dinitramide / aluminum trihydride (ADN / AlH) of the present invention 3 ) The preparation method of composite microspheres is to combine precipitation by in situ self-assembly method, comprising the following steps:

[0058] (1) After dissolving ADN in the solvent, add the precursor of the first reactive protective layer and stir evenly for later use. The first reactive protective layer includes a prepolymer, a curing agent, and a catalyst, and the stirring time is 20 to 30 minutes , the rotation speed is 400-800rpm, the prepolymer is one of hydroxyl-terminated glycidyl ether (GAP), hydroxyl-terminated polybutadiene (HTPB) or hydroxyl-terminated perfluoropolyether (PFPE), and the curing agent is Isophor One or a combination of ketone diisocyanate (IPDI), toluene diisocyanate (TDI) or polyfunctional aliphatic isocyanate (N-100), the catalyst is di-n-butyltin dilaurate.

[0059] (2) AlH 3 Put it into a beaker, add anti-solvent, and ultrasonically pulverize it in a...

Embodiment 1

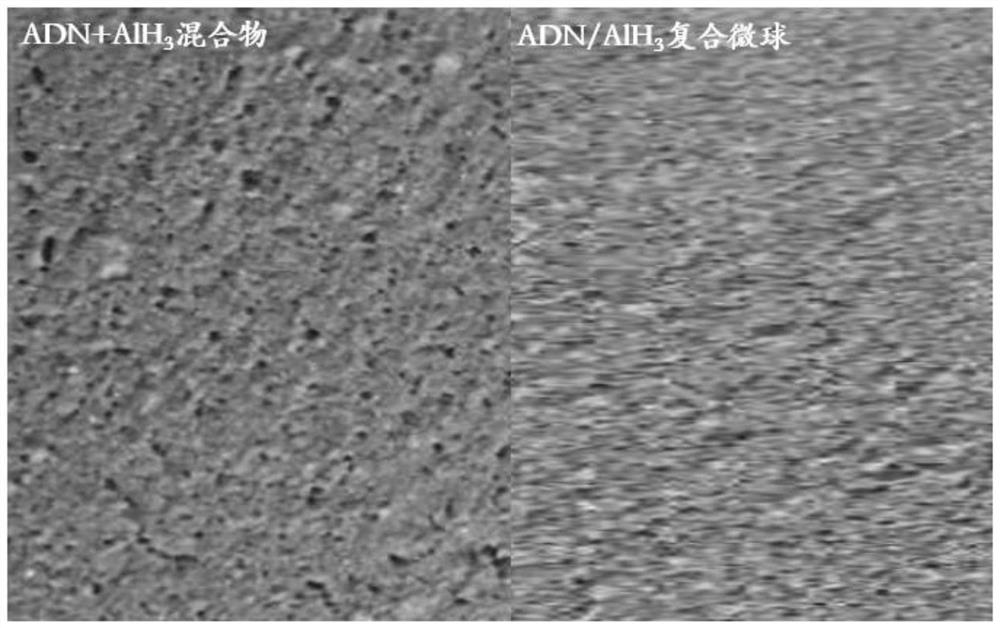

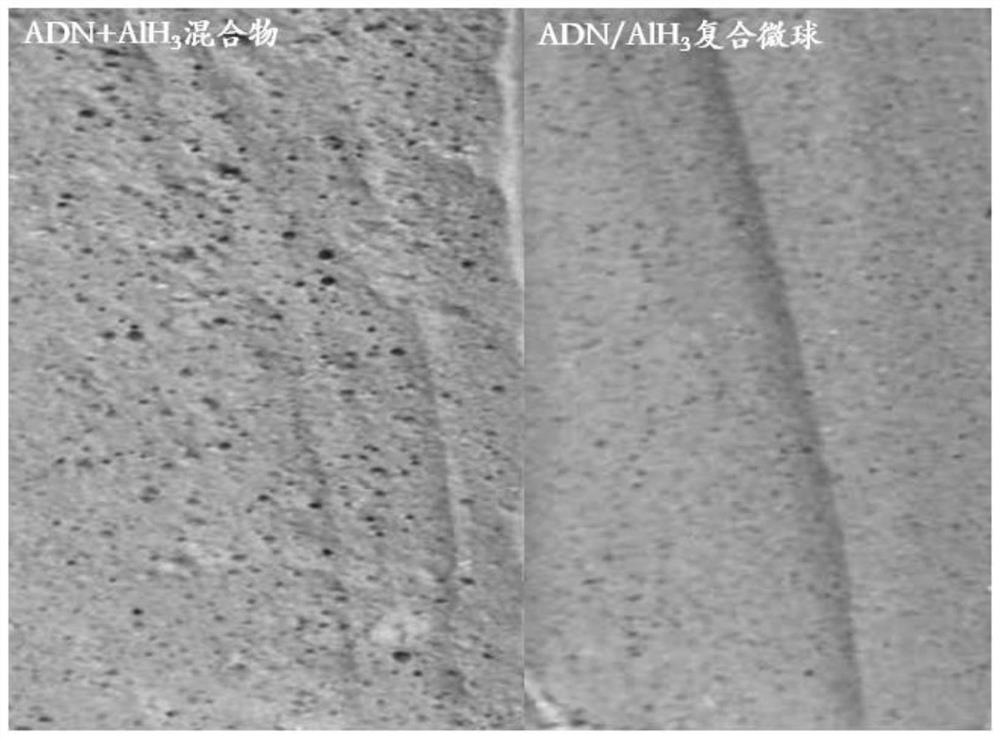

[0088] Dissolve 5gADN and 0.2g of HTPB glue+TDI curing agent+organotin catalyst completely in 20mL acetonitrile; 5gAlH 3 Put it into a beaker, add 100ml of anti-solvent dichloromethane, under the double action of stirring and ultrasonic, keep AlH 3 In a suspension state, the ultrasonic power is 700W, and the stirring speed is 1000rpm; the ADN solution is added dropwise at a rate of 0.2ml / min to a concentration of 5gAlH 3 Keep the temperature at 40°C, the ultrasonic power at 700W, and the stirring speed at 1000rpm, and react for 3 hours; then add 20mL of acetonitrile solution containing 0.5g of HTPB glue + TDI curing agent + organotin catalyst Add to the above solution, continue to react for 12h, cool to room temperature, filter, and vacuum dry to obtain off-white ADN / AlH 3 Composite energetic microspheres. Take 5gADN / AlH 3 Composite energetic microspheres and 5g of ADN and AlH3 mixture with a mass ratio of 1:1 were tested for hygroscopicity at a relative humidity of 75% and...

Embodiment 2

[0090] Dissolve 8g of ADN and 0.12g of GAP glue + TDI curing agent + organotin catalyst in 20mL of acetone; 4g of AlH 3 Put it into a beaker, add anti-solvent cyclohexane 100ml, under the double action of stirring and ultrasonic, keep AlH 3 In a suspension state, the ultrasonic power is 700W, and the stirring speed is 800rpm; the ADN solution is added dropwise at a rate of 0.5ml / min to the solution containing 4gAlH 3 In the cyclohexane dispersion, keep the temperature at 50°C, the ultrasonic power is 700W, the stirring speed is 800rpm, and react for 3h; then add 20mL of acetone solution containing 0.6g of PFPE glue + TDI curing agent + organotin catalyst Add to the above solution, continue to react for 8h, cool to room temperature, filter, and vacuum dry to obtain off-white ADN / AlH 3 Composite energetic microspheres. Take 5gADN / AlH 3 Composite energetic microspheres and 5g of ADN and AlH with a mass ratio of 2:1 3 The mixture was tested for hygroscopicity at a relative hum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com