Efficient production method of glyphosate isopropylamine salt

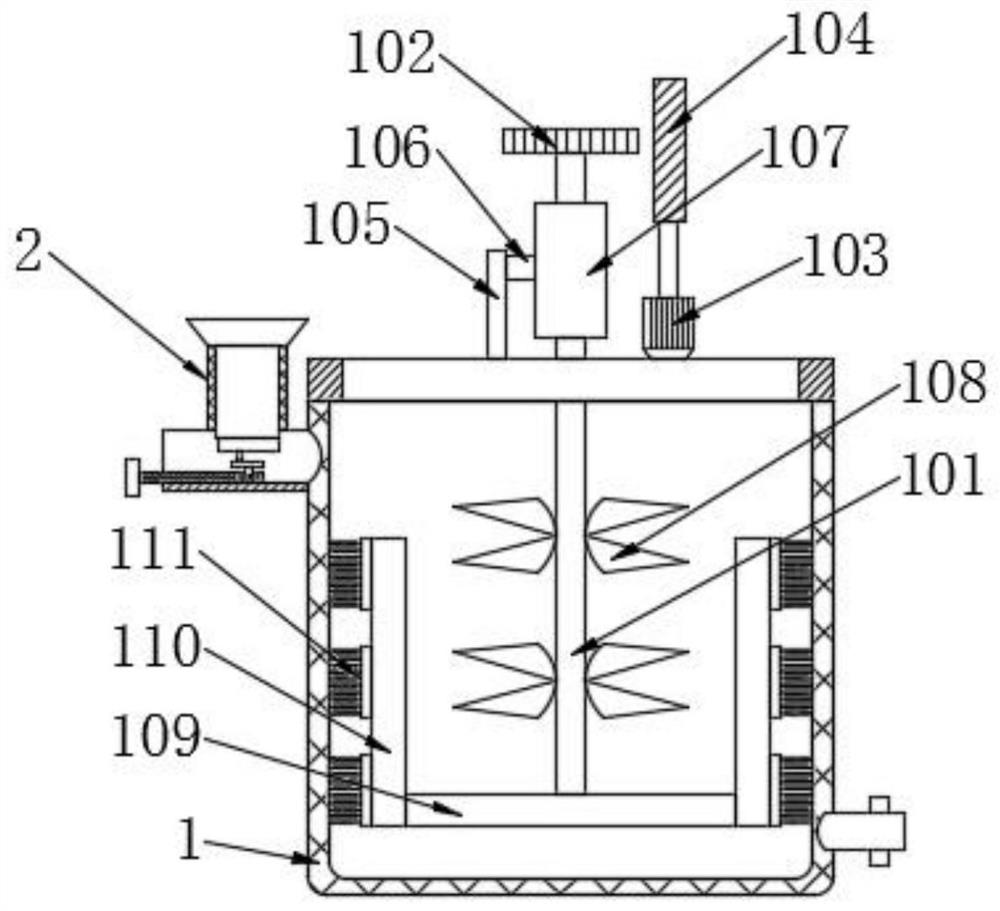

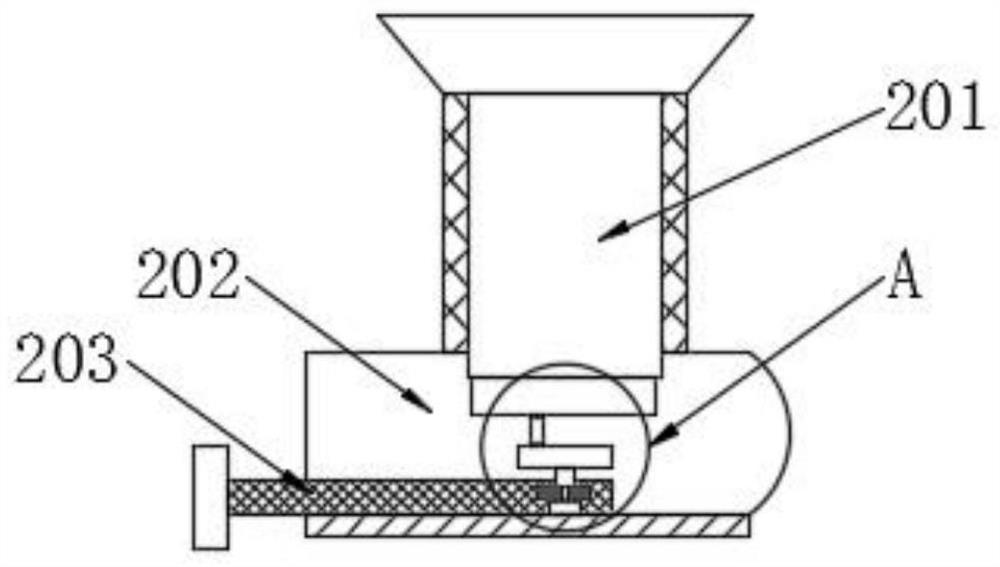

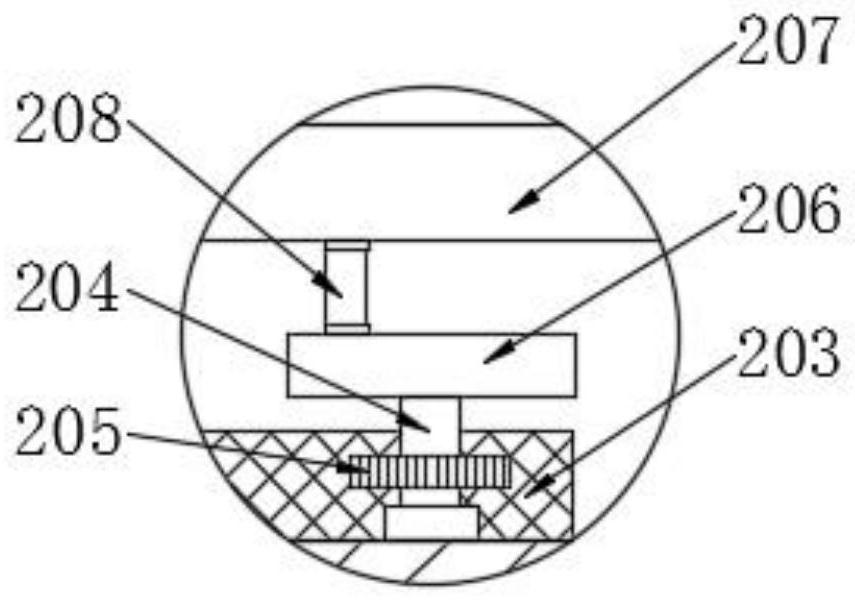

The technology of a glyphosate isopropylamine salt and a production method is applied in the field of high-efficiency production of glyphosate isopropylamine salt, which can solve problems such as low production efficiency, material blockage, and insufficient stirring in a stirring tank, so as to improve stirring efficiency and increase Contact area, sufficient mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of efficient production method of glyphosate isopropylamine salt, comprises the steps:

[0035] S1. Weigh the following raw materials in parts by weight: 10 parts of glyphosate, 15 parts of isopropylamine and 30 parts of water;

[0036] S2. Add glyphosate and water into the stirring tank while stirring, and keep stirring to obtain material A;

[0037] S3, put isopropylamine into the reactor, and drop the material A obtained in step S2 into the reactor while stirring;

[0038] S4. When the stirring time is 2 hours, control the temperature in the reactor at 30°C through the condenser, and when the stirring time is 2.5 hours, control the temperature in the reactor at 32°C until the PH in the reactor is <7 , That is, glyphonium isopropylamine salt.

[0039] In step S2, glyphosate and water are simultaneously added into the stirring tank while stirring, and stirred at a temperature of 30° C. for 1 h.

[0040] In step S3, put isopropylamine into the reaction kettle,...

Embodiment 2

[0042] A kind of efficient production method of glyphosate isopropylamine salt, comprises the steps:

[0043] S1. Weigh the following raw materials in parts by weight: 15 parts of glyphosate, 17 parts of isopropylamine and 35 parts of water;

[0044] S2. Add glyphosate and water into the stirring tank while stirring, and keep stirring to obtain material A;

[0045] S3, put isopropylamine into the reactor, and drop the material A obtained in step S2 into the reactor while stirring;

[0046]S4. When the stirring time is 2.2h, the temperature in the reactor is controlled at 30.5°C through the condenser, and when the stirring time is 2.7h, the temperature in the reactor is controlled at 35°C until the pH in the reactor is < 7, namely glyphonium isopropylamine salt.

[0047] In step S2, glyphosate and water were simultaneously added into the stirring tank while stirring, and stirred at a temperature of 31° C. for 1.2 h.

[0048] In step S3, put isopropylamine into the reactor, a...

Embodiment 3

[0050] A kind of efficient production method of glyphosate isopropylamine salt, comprises the steps:

[0051] S1. Weigh the following raw materials in parts by weight: 20 parts of glyphosate, 20 parts of isopropylamine and 40 parts of water;

[0052] S2. Add glyphosate and water into the stirring tank while stirring, and keep stirring to obtain material A;

[0053] S3, put isopropylamine into the reactor, and drop the material A obtained in step S2 into the reactor while stirring;

[0054] S4. When the stirring time is 2.5 hours, control the temperature in the reactor at 31°C through the condenser, and when the stirring time is 3 hours, control the temperature in the reactor at 40°C until the pH in the reactor is <7 , That is, glyphonium isopropylamine salt.

[0055] In step S2, glyphosate and water were simultaneously added into the stirring tank while stirring, and stirred at a temperature of 32° C. for 1.5 h.

[0056] In step S3, put isopropylamine into the reaction kett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com