Rust remover and preparation method thereof

A technology of rust remover and auxiliary agent, applied in the petroleum industry, lubricating composition and other directions, can solve the problems of insufficient output, complicated process, increase the time of rust remover, etc., to achieve less water leakage, reduce heat loss, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

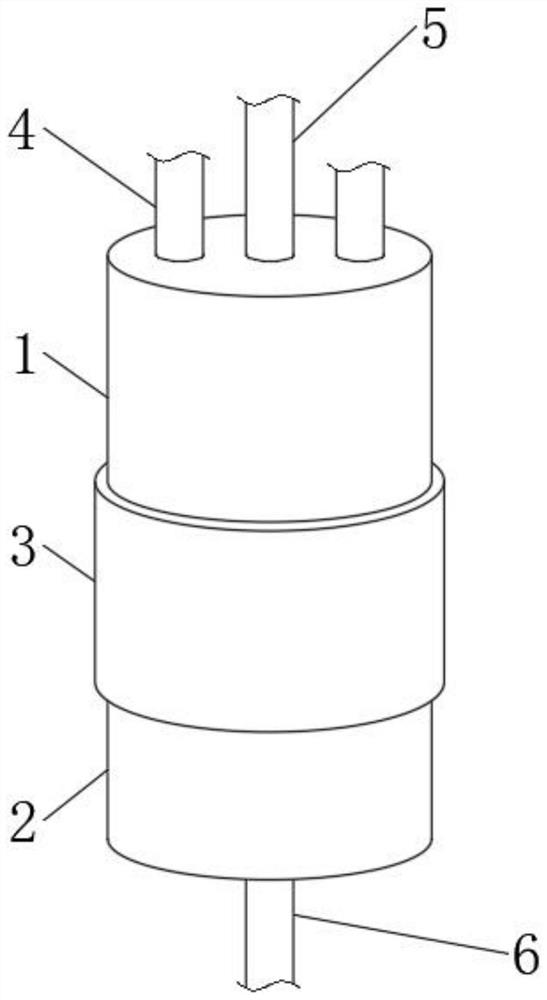

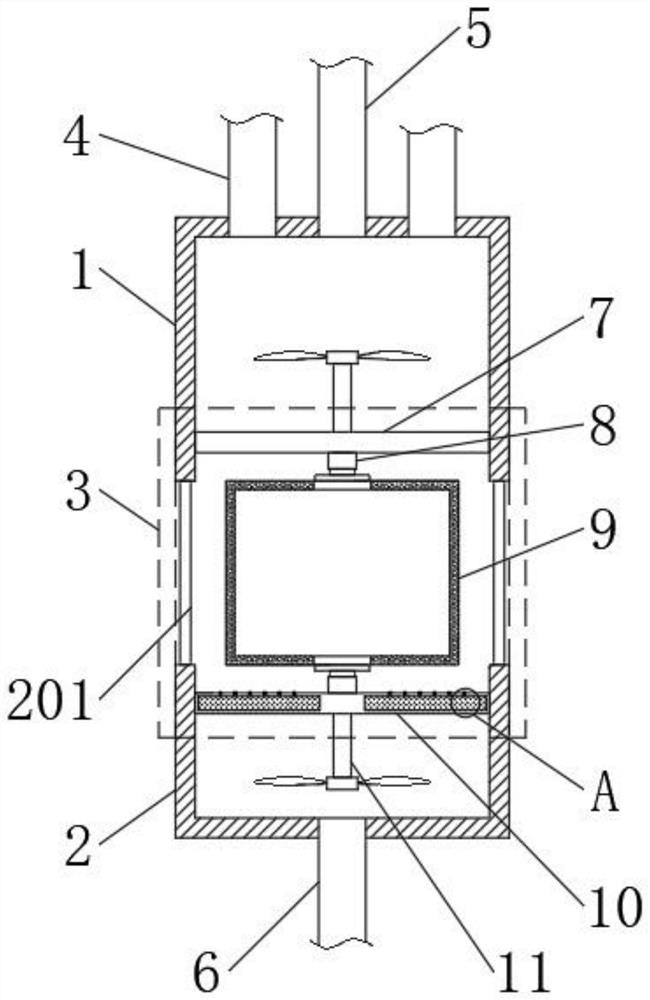

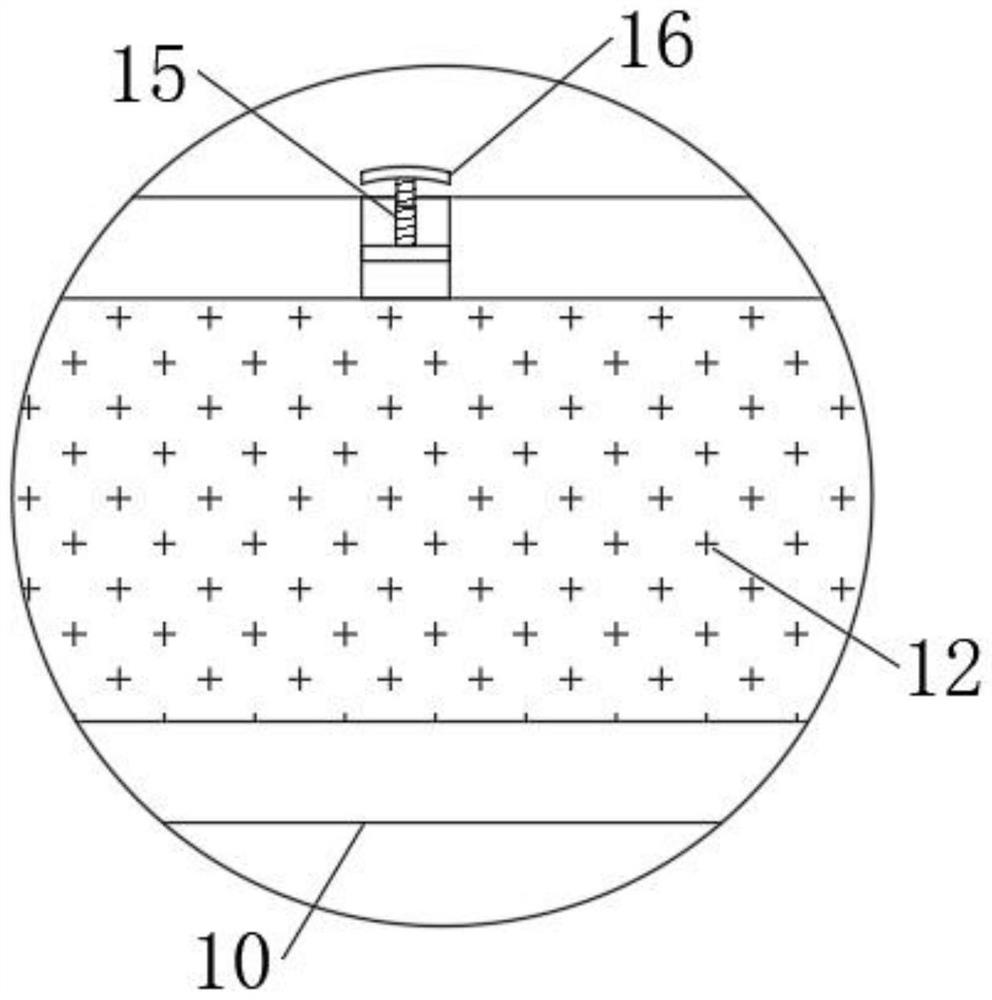

[0044] see Figure 1-6 , a rust remover, comprising molybdenum-containing compound, graphene composite material, biochar active matter, auxiliary agent, dispersant, polyaspartic acid and sodium citrate, the preparation method comprising the following steps:

[0045] S1. Set at 20°C, take 15 parts of molybdenum-containing compound, 8 parts of biochar active matter, 4 parts of auxiliary agent, and 25 parts of water in the potential energy reactor according to the number of parts by mass;

[0046] S2, and the mixture in S1 is warmed up to 50, adds 8 parts of dispersants, 20 parts of graphene composite materials;

[0047] S3. Mix and stir the mixture in S2 for 20 minutes, then cool to room temperature, adjust the pH, add 15 parts of polyaspartic acid and 6 parts of sodium citrate, disperse with ultrasonic waves for 30 minutes, and evaporate to 40% of the original volume under vacuum , that is, rust remover.

[0048] see Figure 1-2 , the potential energy reactor includes an upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com