Acceleration test profile optimization method and system, electromechanical product, medium and terminal

A technology for accelerated testing, electromechanical products, applied in design optimization/simulation, electrical digital data processing, computer-aided design, etc. It can solve problems such as failure to consider the impact of test results, inaccurate life evaluation, and inability to guide stress transition time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

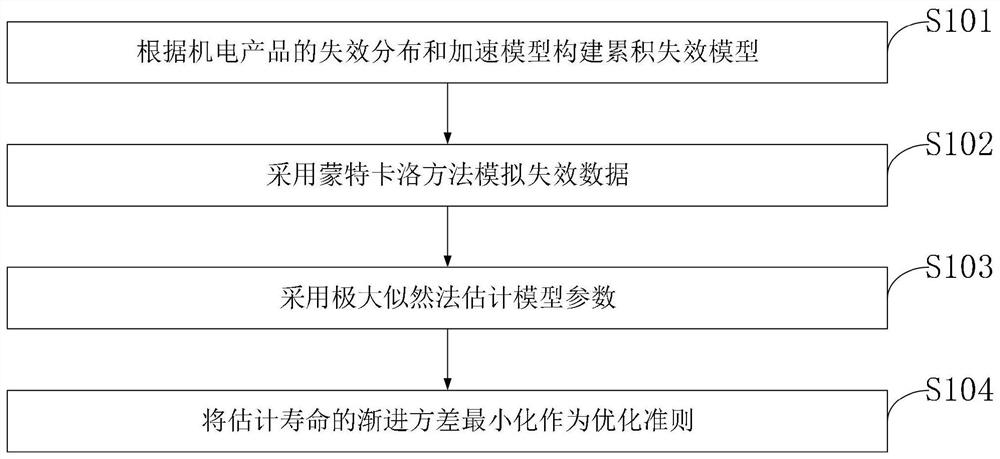

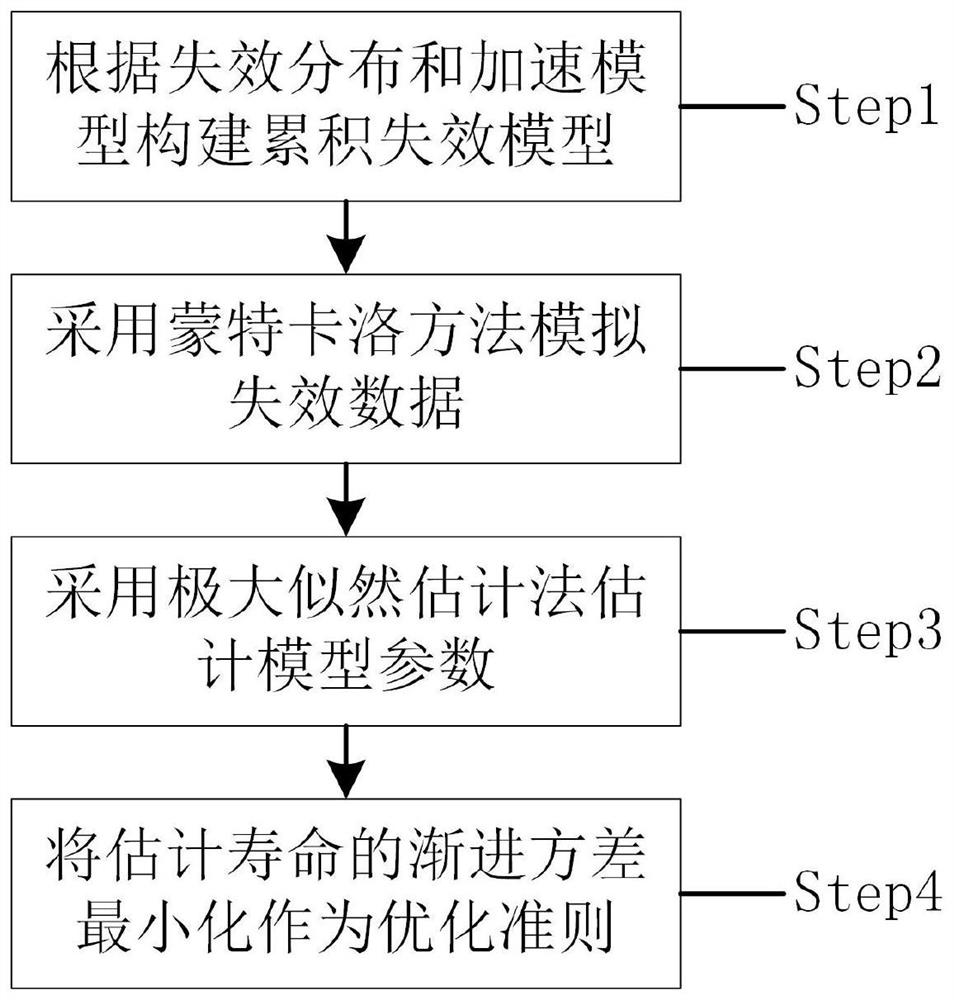

[0128] Such as figure 2 As shown, the present invention is specifically realized through the following process:

[0129] 1) Construct the cumulative failure model according to the failure distribution and acceleration model of electromechanical products:

[0130] 1 Determine the accelerated test profile and design variables

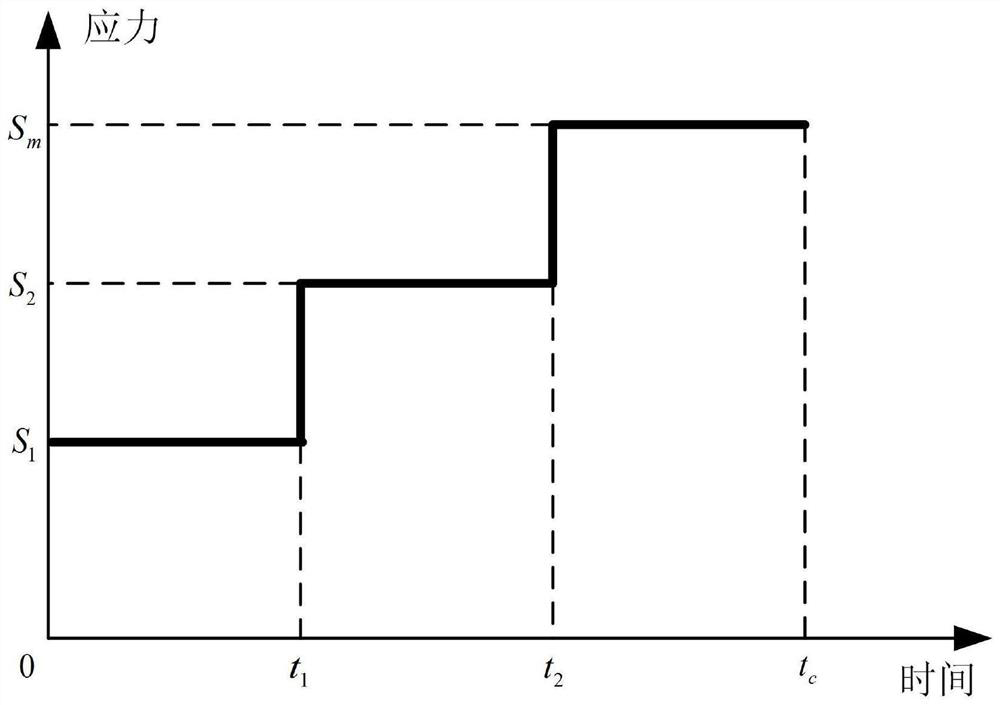

[0131] In order to facilitate the analysis, the present invention will optimize the design of the three-step acceleration test section. Such as image 3 Shown, S m In order not to change the maximum accelerated stress of the failure mechanism, it can be determined according to a small amount of preliminary tests or simulations; t c It is the cut-off time of the test, which can be determined according to engineering experience or a small amount of preliminary tests; S 1 and S 2 is the accelerated stress level; t 1 and t 2 is the stress conversion time; S 0 The normal working stress level for the product.

[0132] Due to the large number of param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com