Full-color SMD LED with enhanced waterproof performance

A LED chip and performance technology, applied in the direction of instruments, electrical components, electric solid devices, etc., can solve the problems of double-electrode chip electrode metal migration failure, colloid and substrate delamination, silver colloid delamination failure, etc., to achieve air tightness Good, the degree of delamination is reduced, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

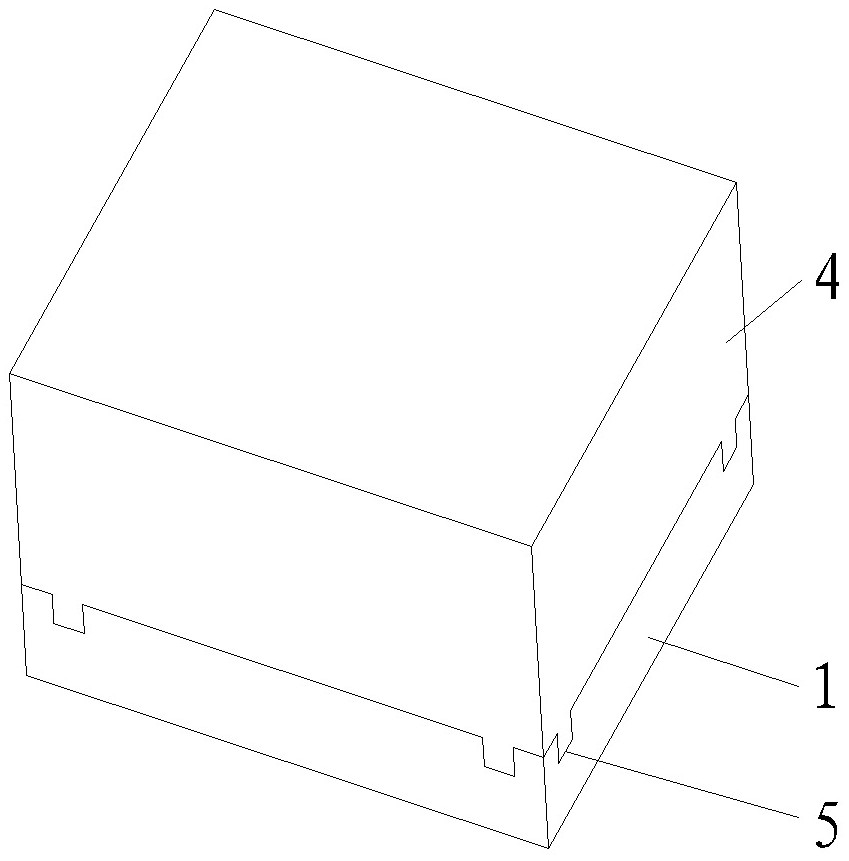

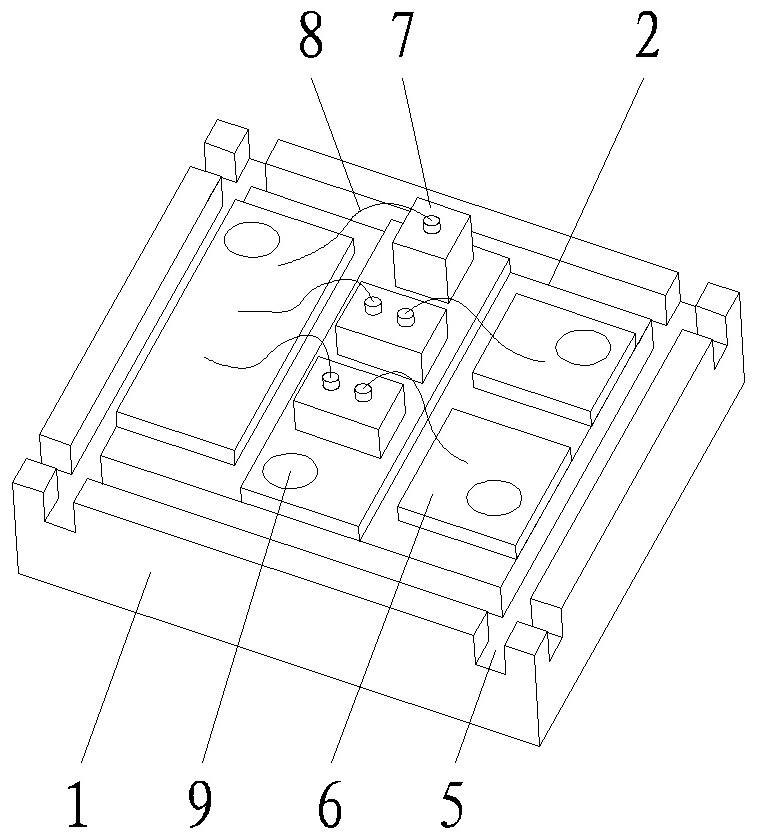

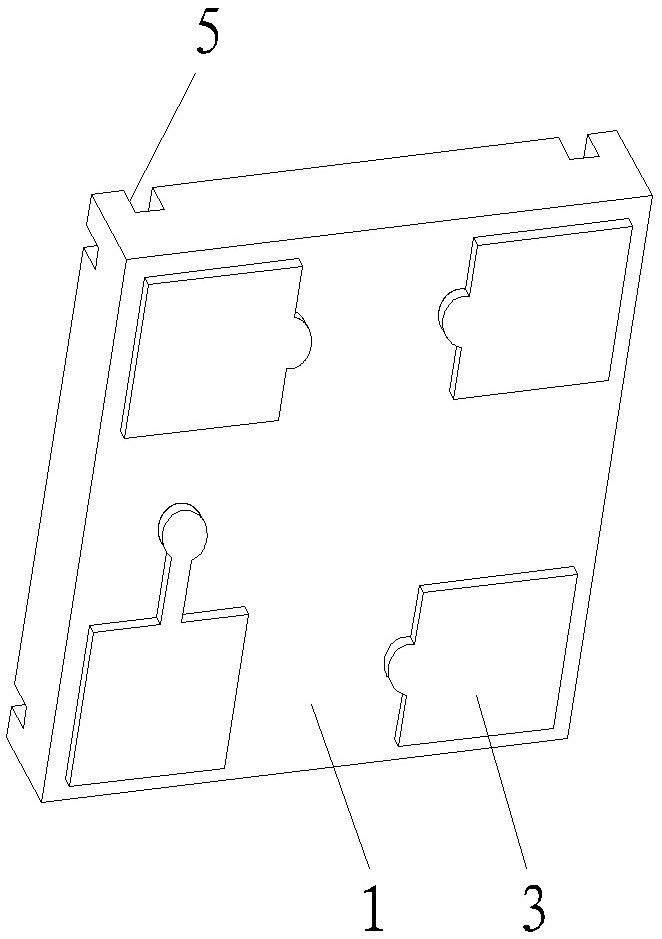

[0015] Such as Figure 1 to 3 As shown, a full-color SMD LED that enhances waterproof performance includes a substrate 1, and is provided on the LED function zone 2 on the upper surface of the substrate 1, and the electrode 3 is provided on the lower surface of the substrate 1, and the package colloid 4 is provided on the substrate 1. The substrate 1 is located at the upper surface of the LED functional region 2, and the waterproof groove 5 is provided, the waterproof groove 5 is a concave tank structure, which is lower than the LED function zone 2, so the functional zone is equivalent to a boss, and when the mold is packaged. The glue is combined with three faces of each groove, and the encapsulation colloid 4 is embedded in the waterproof groove 5 to form a waterproof structure, effectively preventing moisture from directly entering the row from the lamp beads directly into the functional region. The substrate 1 is provided with a through hole of the LED function zone 2, the elec...

Embodiment 2

[0017] Such as Figure 1 to 3 As shown, a full-color SMD LED, which enhances waterproof performance, as in the example, the only difference is that the blind hole 9 does not plug the hole treatment, and the encapsulation colloid is injected through the front of the hole, and finally fill the entire blind. Hole 9.

[0018] The type of lamp beads used in the present invention includes a single separation device, a plurality of integrated devices.

[0019] The process steps of the present invention are as follows:

[0020] Step 1: The substrate 1 is processed;

[0021] Step 2: Substrate 1 plasma cleaning treatment;

[0022] Step 3: Substrate 1 solid crystal, welding wire or flip chip solid crystal;

[0023] Step 4: Sprinkling or vacuum coating is performed on the surface of the semi-finished LED functional region 2 using the Presin Gabani inorganic material mixture coating. The film layer of spray or vacuum vapor deposition is first cured, and the film layer after curing is optical tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com