Method for preparing oil-in-water emulsion by using D-phase emulsification method and application of method

A technology of oil-in-water emulsion and emulsification method, which is applied in the field of preparation of oil-in-water emulsion and oil-in-water emulsion by using D-phase emulsification method, which can solve the problems of dispersibility, poor stability, high emulsifier dosage, skin Irritation and other problems, to achieve good stability, reduce greasy, uniform size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

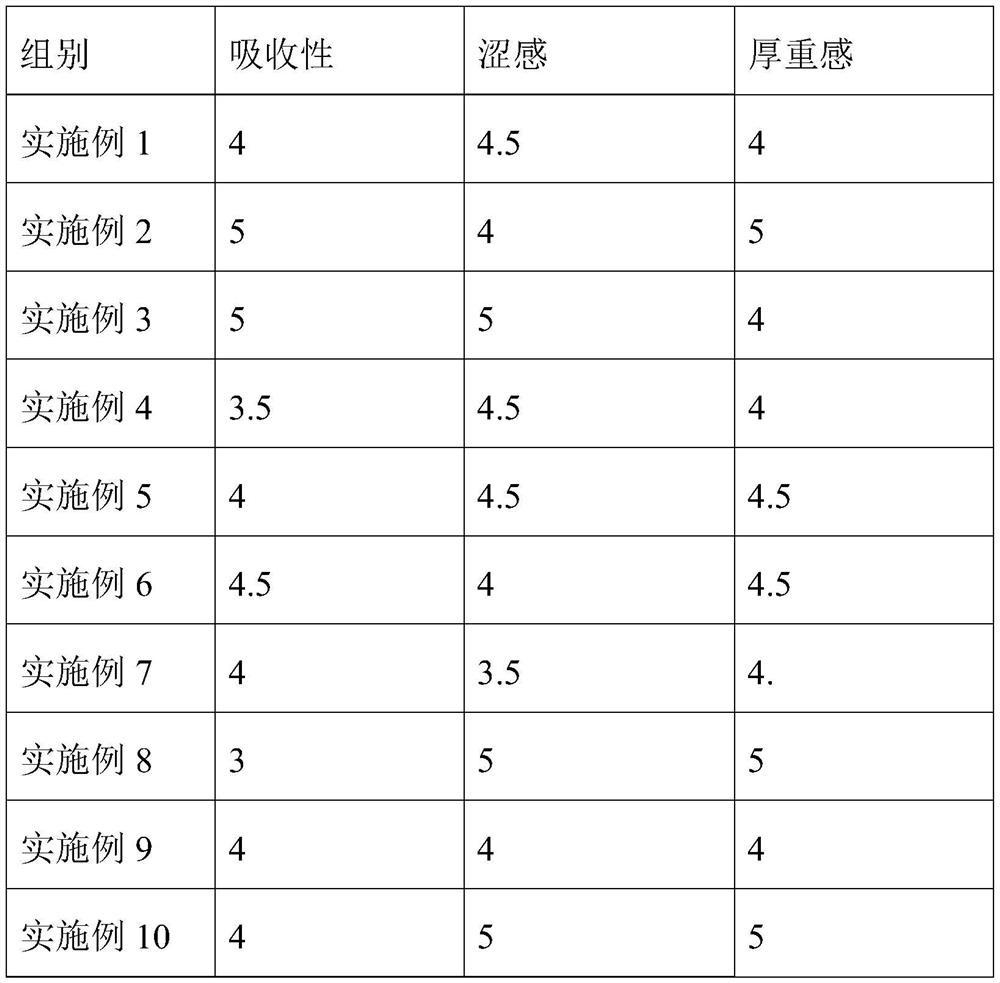

Examples

Embodiment 1

[0048] This embodiment provides an oil-in-oil emulsion, which prepares a material having a D-phase (4% butanediol, 3%, PEG40 hydrogenated castor oil 1%, pure water 2%), II phase (Hobham seed oil 16) %), Phase III (pure water 2%) and IV phase (pure water). The preparation method is as follows:

[0049] (1) Heat the D phase, II phase from 80 ° C to dissolve;

[0050] (2) Emulsified 8 min after the dissolved D phase, II phase mixed homogenization was carried out at 8000 rpm velocity and 70 ° C;

[0051] (3) The product of the step (2) is mixed with III at 5000 rpm velocity, stirred at 70 ° C for 15 min;

[0052] (4) The product was mixed with the IV phase at 5000 rpm velocity, stirred at 70 ° C for 15 min to give the water-filled emulsion.

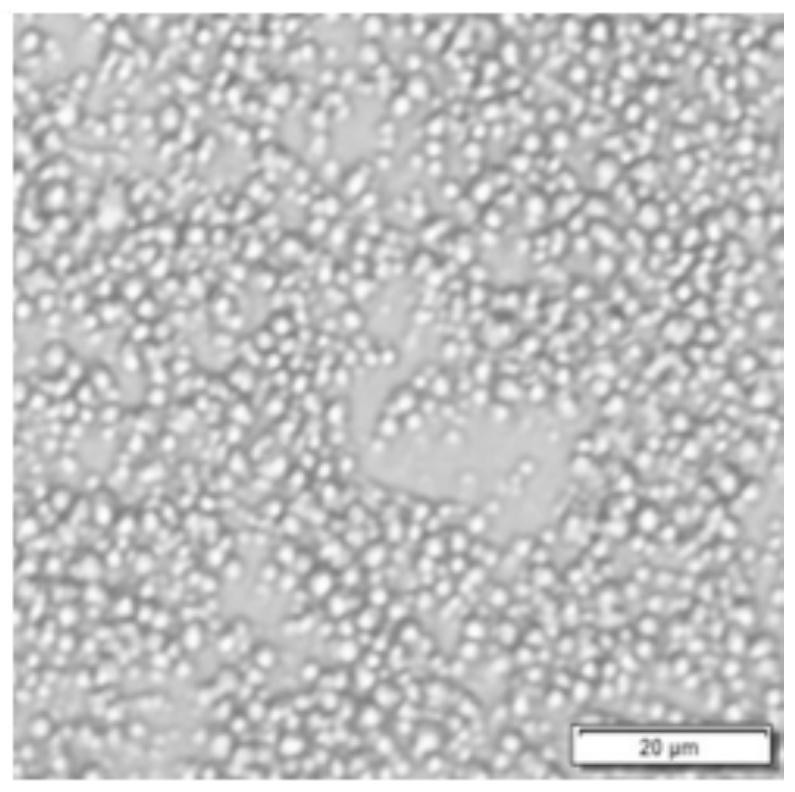

[0053] The obtained water-in-oil emulsion was observed with TEM, such as figure 1 As shown: Emulsified particles are uniform and the particle size is small.

Embodiment 2

[0055] This embodiment provides an oil-in-water type emulsion, and the difference between the preparation of the raw material and the first embodiment is only to replace the PEG40 hydrogenated castor oil to replace the IV phase (pure water) to IV phase (essence) The amount of liquid remaining), the other components and the content remain unchanged. The preparation method is the same as in Example 1.

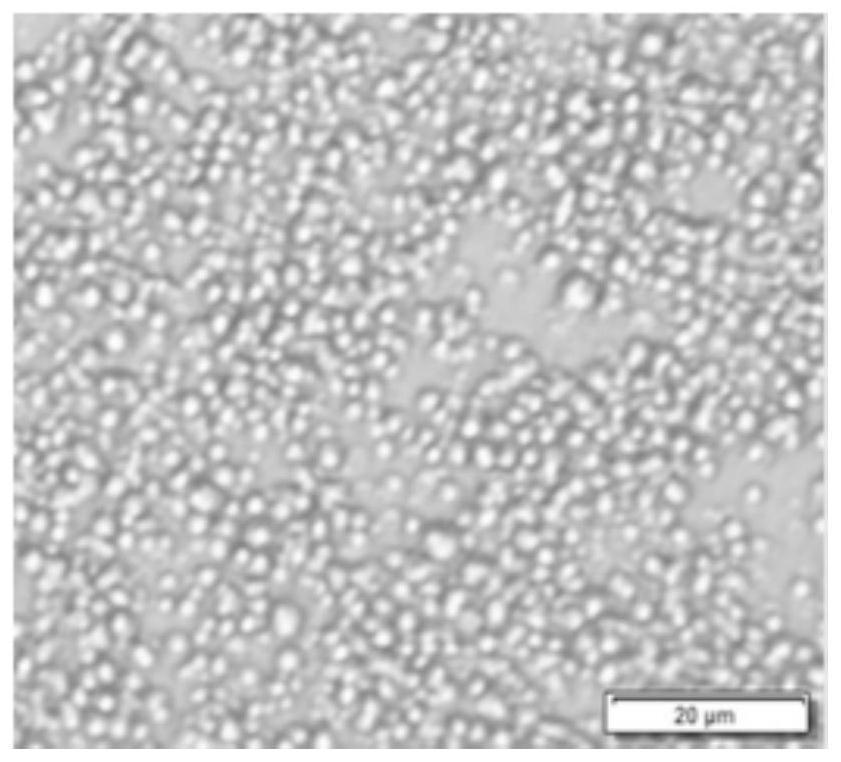

[0056] The obtained water-in-oil emulsion was observed with TEM, such as figure 2 As shown: Emulsified particles are uniform and the particle size is small.

Embodiment 3

[0058] This embodiment provides an oil-in-oil emulsion, and the difference in the preparation of the raw material and the first embodiment is only to replace the PEG40 hydrogenated castor oil to PEG80 hydrogenated castor oil, other components and content remain unchanged. The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com