A composite material hole processing pcd drilling and milling chamfering tool

A composite material and chamfering tool technology, which is applied in milling cutters, manufacturing tools, drilling accessories, etc., can solve problems such as poor shock absorption effect, and achieve the effects of avoiding drill bit damage, improving surface roughness, and maintaining precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

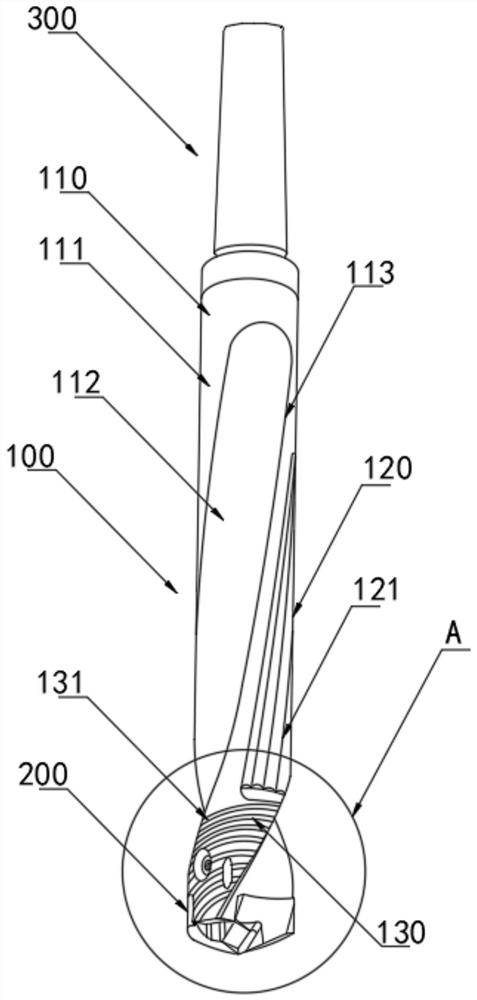

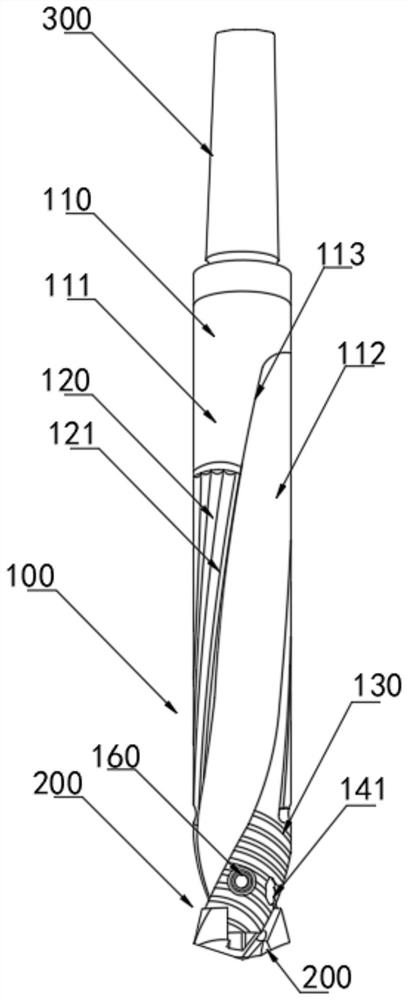

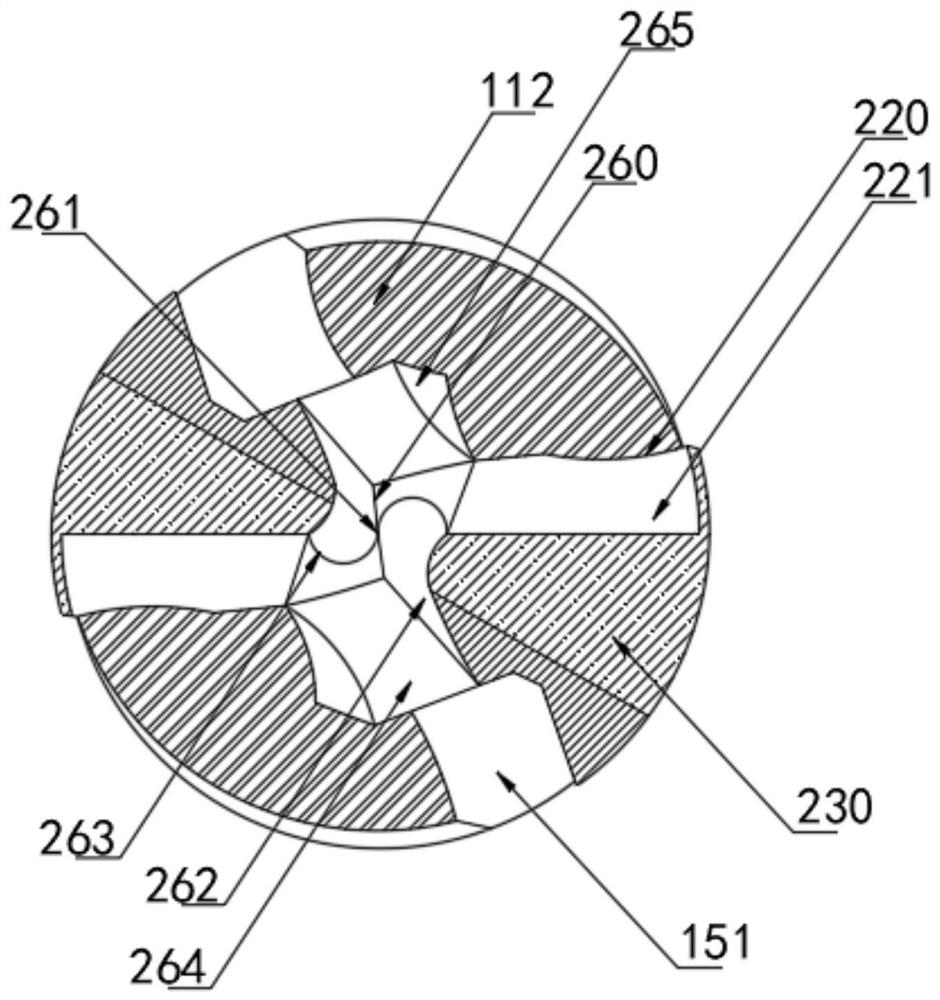

[0034] Embodiment 1, with reference to attached Figure 1-11 , a composite material hole processing PCD drilling and milling chamfering tool provided by the present invention includes a drill rod 100, a cutting head 200 and a tail handle 300. The outer wall of the drill rod 100 is spirally provided with a chip removal groove 112, and the chip removal groove 112 is provided with two There is a knife back 110 between the two groups of chip removal grooves 112, a limit groove 150 is provided on both sides of the bottom of the drill pipe 100, and the chip removal groove 112 extends downward to connect with the limit groove 150, and the bottom of the tool back 110 is fixedly installed with a convex Block 151, drill pipe 100 bottom is provided with through hole 170, and drill pipe 100 bottom is provided with cutting head 200, and cutting head 200 top is fixedly installed limit column 210, and limit column 210 two sides are provided with groove two 211, and cutting head 200 Limiting ...

Embodiment 2

[0045] Refer to the attached Figure 12 , a composite material hole processing PCD drilling and milling chamfering tool of this embodiment also includes an extended drill rod 180;

[0046] Further, the drill rod 100 also includes an extended drill rod 180, the outer wall of the extended drill rod 180 is spirally provided with chip guide grooves 181, and two sets of chip guide grooves 181 are provided. Specifically, according to the different hole depths, the extended drill rod 180 and the drill bit Choose according to the multiple diameter. When drilling on the CNC, the drill pipe 100 with a small multiple diameter ratio is more rigid. When the cutting head 200 drills to the bottom, the chips can be removed smoothly. If the length is not enough, the surface finish will deteriorate. , The problem of unequal hole diameter and drill bit breakage, chips will block the sub-flutes, and the extended drill rod 180 needs to be used to solve the problem.

[0047] The specific implement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com