Electric spark machining method for small-size spaceflight impact type turbine blade fatigue sample

A technology of impingement turbines and fatigue samples, which is applied in the direction of electric processing equipment, metal processing equipment, manufacturing tools, etc., to achieve the effect of simple experimental verification procedures, extensive manufacturing channels, and convenient control of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

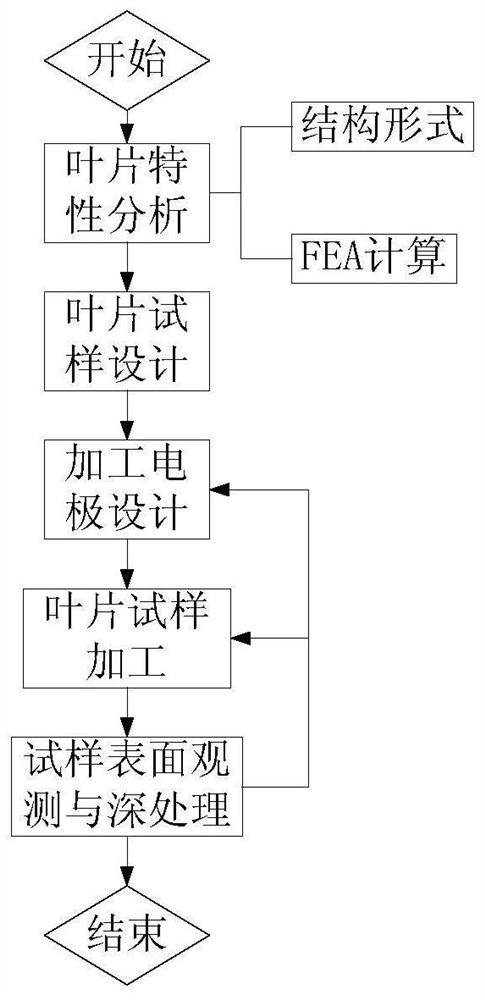

[0054] Such as figure 1 Shown, the electrical discharge machining method of the small size aerospace impact type turbine blade fatigue sample of the present invention, the step comprises:

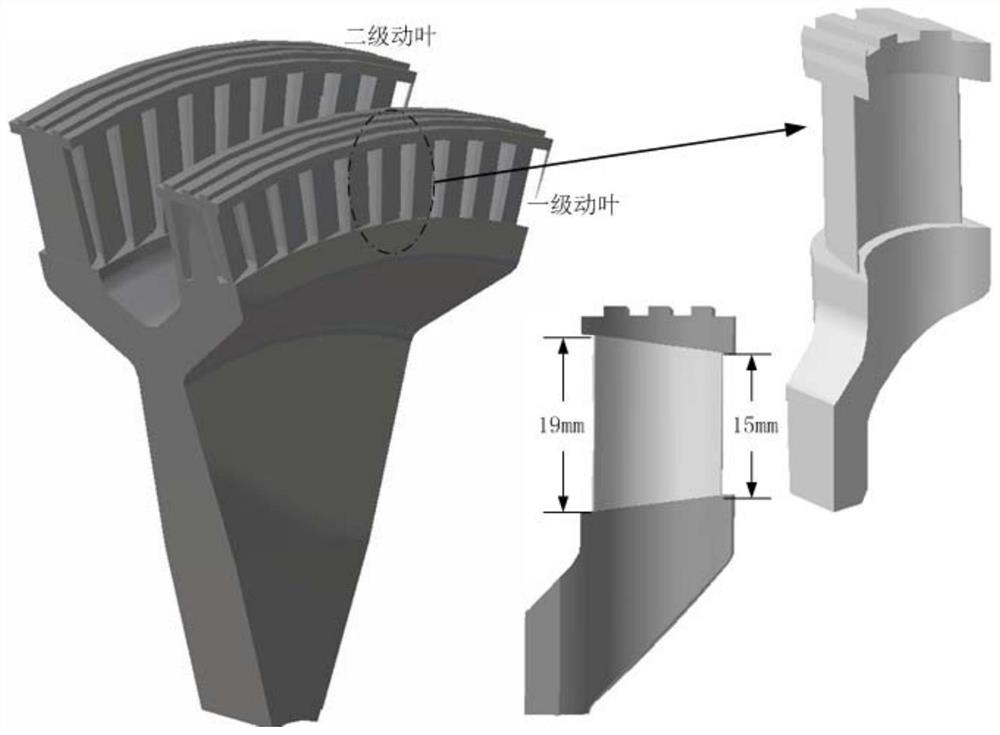

[0055] Step 1: Analyze the basic structure of the blade, understand the size and shape characteristics of each part of the blade, and the actual appearance of some blades is as follows figure 2 shown. Using the finite element method to calculate the mechanical response characteristics of the blade model, the mesh division is as follows Figure 7 As shown in (a), on this basis, the part of the leading edge of the blade close to the blade root is selected as the fatigue life assessment site.

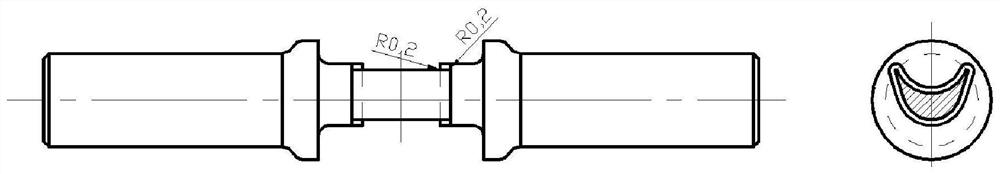

[0056] Step 2, use CATIA three-dimensional drawing software to draw the blade fatigue sample model, and use AutoCAD two-dimensional drawing software to complete the drawing design of the blade fatigue sample, such as image 3 shown.

[0057] When drawing the fatigue sample model, design the experim...

Embodiment approach

[0072] Its specific implementation is as follows:

[0073]The first step: Use a CNC lathe to process the metal bar into a workpiece directly used for EDM machining. The workpiece consists of three sections, the middle section is a cylindrical section, and there is a clamping section at each end. The cylindrical section and the clamping section There is a transition link between the sections, and the slope angle of the transition link is 45°, such as Figure 5 as shown in (a);

[0074] The second step: use the electric discharge machine tool to install the workpiece processed in the first step on the Figure 5 In the station shown in (b), it is used in the way of oil immersion processing Figure 4 The processing electrode for the transition section on the pressure side shown in (a-1) completes the machining of the transition section on the pressure side. For the specific forming process, see Figure 5 Medium (b-1);

[0075] Step 3: Keep the station in the second step, use t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com