Forming method capable of improving dimensional precision of carbon fiber filling core material

A molding method and dimensional accuracy technology, which is applied in the field of automatic composite material manufacturing, can solve problems such as excessive use of tooling and molds, affect manufacturing efficiency, and complex processing technology, and achieve improved compactness, smooth surface quality, and reduced porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

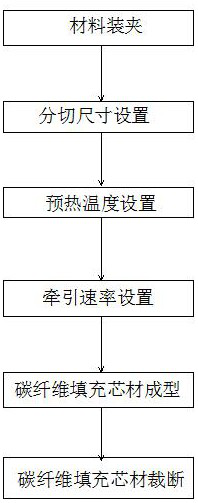

[0044] see figure 1 , a method for improving the dimensional accuracy of a carbon fiber filled core material, comprising the following steps:

[0045] a. Material clamping, select prepreg, and clamp the prepreg on the carbon fiber filled core material automatic forming equipment; transfer the remaining material and backing paper to the rotary mechanism for the remaining material of the lining paper, and transfer the lining film to the In the rotary mechanism of the lining film, the other end of the material is clamped by a chuck to form a traction state;

[0046]b. Cutting size setting, calculate the cross-sectional area of the carbon fiber-filled core material according to the length L, height H and radius of the carbon fiber-filled core material; then calculate the single-layer pre-preparation required for the carbon fiber-filled core material according to the cross-sectional area and material thickness h Dip material width W, and then set the cutting size with the width ...

Embodiment 2

[0053] see figure 1 , a method for improving the dimensional accuracy of a carbon fiber filled core material, comprising the following steps:

[0054] a. Material clamping, select prepreg, and clamp the prepreg on the carbon fiber filled core material automatic forming equipment; transfer the remaining material and backing paper to the rotary mechanism for the remaining material of the lining paper, and transfer the lining film to the In the rotary mechanism of the lining film, the other end of the material is clamped by a chuck to form a traction state;

[0055] b. Cutting size setting, calculate the cross-sectional area of the carbon fiber-filled core material according to the length L, height H and radius of the carbon fiber-filled core material; then calculate the single-layer pre-preparation required for the carbon fiber-filled core material according to the cross-sectional area and material thickness h Dip material width W, and then set the cutting size with the width...

Embodiment 3

[0063] see figure 1 , a method for improving the dimensional accuracy of a carbon fiber filled core material, comprising the following steps:

[0064] a. Material clamping, select prepreg, and clamp the prepreg on the carbon fiber filled core material automatic forming equipment; transfer the remaining material and backing paper to the rotary mechanism for the remaining material of the lining paper, and transfer the lining film to the In the rotary mechanism of the lining film, the other end of the material is clamped by a chuck to form a traction state;

[0065] b. Cutting size setting, calculate the cross-sectional area of the carbon fiber-filled core material according to the length L, height H and radius of the carbon fiber-filled core material; then calculate the single-layer pre-preparation required for the carbon fiber-filled core material according to the cross-sectional area and material thickness h Dip material width W, and then set the cutting size with the width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com