Biological reaction filler prepared by embedding microorganisms into microporous membrane

A biological reaction and microporous membrane technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as low activity, packing loss, clogging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1 Anti-nitrogenated bacteria was embedded in a hollow fiber membrane to produce bioreactic filler:

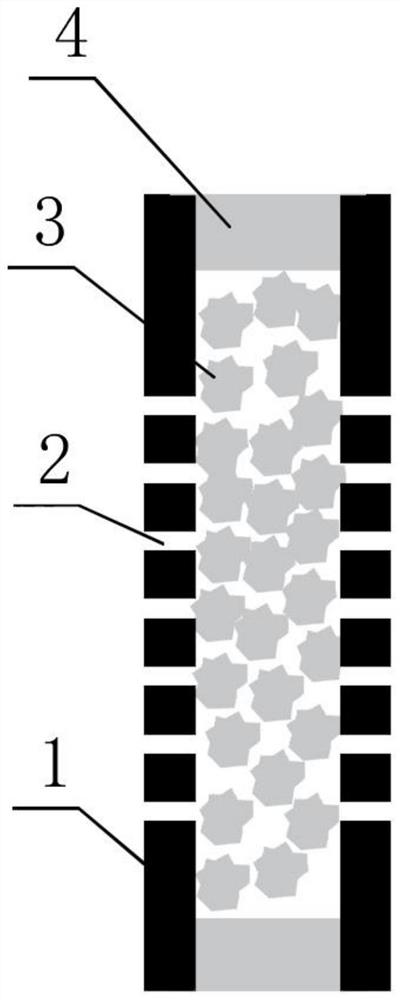

[0053] according to figure 1 The structure shown is embedded in a hollow fiber membrane (active sludge) containing contact with denitrifuginal. The hollow fiber membrane is made of PVDF, the inner diameter of 2 mm, the film thickness of the film is 0.5 mm, the aperture pore diameter on the outer wall is 320 nm, and the nitrogenation adhesive group (active sludge) particle size is about 400 nm (aperture and particle diameter ratio ratio) Set by the following proportion: set the average size of microporous membrane holes to D 1 , The average particle size of the bacteria colon is d. 2 Others 1 di 1 ≤ D 2 ≤n 2 di 1 Time, for the best ratio, where η 1 , Η 2 Constant, η 1 Take the value of 1.23, η 2 The value is 1.61), so that the nitroration group is wrapped by the microporous membrane will not be lost. According to the engineering application, a hollow fiber membrane i...

Embodiment 2

[0060] Example 2 Anti-nitrogenated bacteria was embedded in a hollow fiber membrane to produce bioreactic filler:

[0061] according to figure 1 The structure shown is embedded in a hollow fiber membrane (active sludge) containing contact with denitrifuginal. The hollow fiber membrane is made of PVDF, the inner diameter of 2 mm, the film thickness of the film is 0.5 mm, the aperture pore size on the outer wall is 240 nm, and the denitrification bacterial adhesive (active sludge) particle size is about 400 nm (aperture and particle size) The ratio is set in the following scale: set the average size of microporous membrane holes to D. 1 , The average particle size of the bacteria colon is d. 2 Others 1 di 1 ≤ D 2 ≤n 2 di 1 Time, for the best ratio, where η 1 , Η 2 Constant, η 1 Take the value of 1.23, η 2 The value is 1.61) so that the denitrifying bacteria is wrapped by microporous membranes. According to the engineering application, a hollow fiber membrane is selected in length, ...

Embodiment 3

[0081] Example 3 Anti-nitrogenated bacteria was embedded in a hollow fiber membrane to produce bioreactic filler:

[0082] according to figure 1 The structure shown is embedded in a hollow fiber membrane (active sludge) containing contact with denitrifuginal. The hollow fiber membrane is made of PVDF, the inner diameter is 2 mm, the film thickness of the film is 0.5 mm, the aperture pore size on the outer wall is 320 nm, and the denitrification bacteria (active sludge) particle size is about 400 nm (aperture and particle size) The ratio is set in the following scale: set the average size of microporous membrane holes to D. 1 , The average particle size of the bacteria colon is d. 2 Others 1 di 1 ≤ D 2 ≤n 2 di 1 Time, for the best ratio, where η 1 , Η 2 Constant, η 1 Take the value of 1.23, η 2 The value is 1.61) so that the denitrifying bacteria is wrapped by microporous membranes.

[0083] Substate (active sludge) was added to a neutral protease of 1 million u / g prior to use, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com