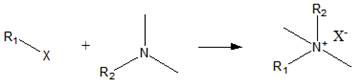

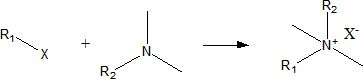

Synthesis process of dialkyl dimethyl ammonium chloride

A technique for the synthesis of dialkyl dimethyl ammonium halides, which is applied in the field of synthesis processes of dialkyl dimethyl ammonium halides, can solve problems such as low safety, complex processes, and high costs, and achieve increased safety and process The effect of simple process and equipment and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 157g of octyl dimethyl tertiary amine and 148g of 1-chlorooctane into the autoclave, seal it and place it in an oven raised to 130°C in advance, and react at a constant temperature for 4 hours. After cooling down, add 300g of it in a volume ratio of 5:1 The mixed solution of water and ethanol is diluted to obtain 605 g of dioctyldimethylammonium chloride aqueous solution with an active content of 49.64%. The conversion rate of reaction materials (calculated as tertiary amine) is 98.46% based on product activity (detected by tetraphenylborax titration colorimetric method), and the chloride ion content is 5.79%.

Embodiment 2

[0028] Add 213g of dodecyldimethyl tertiary amine and 204g of 1-chlorododecane into the autoclave, seal it and place it in an oven raised to 150°C in advance, and react at constant temperature for 4 hours. After cooling down, add 400g of volume ratio 3 : 1 water and ethanol mixed solution dilution, get active content and be 50.49% dioctyl dimethyl ammonium chloride aqueous solution 817g. The conversion rate of reaction materials (calculated as tertiary amine) is 98.92% based on product activity (detected by tetraphenylborax titration colorimetric method), and the chloride ion content is 4.30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com